Inspection Microscopes

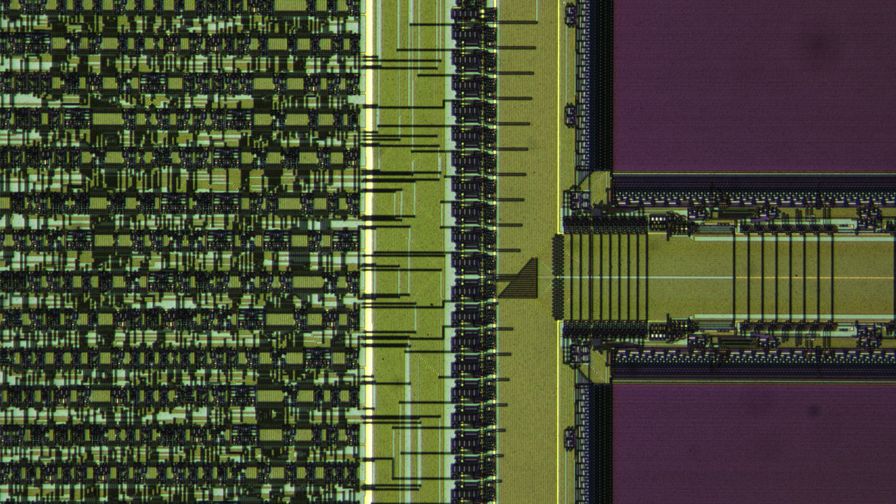

Suppliers and manufacturers need to inspect parts and components to ensure and optimize performance and lifetime. But inspection must also be carried out in an efficient and cost-effective way. The goal is to optimize workflow efficiency for quality control including inspection and rework, failure analysis, and research and development (R&D).

Many different challenges can occur when performing inspection with a microscope. Some of the most critical relate to workflow optimization, efficient reporting of results, training of users, and user comfort. Inspection microscopes from Leica Microsystems can help overcome these challenges.

Contact us for expert advice on the right inspection microscope for your needs and budget.

What are your inspection microscope needs?

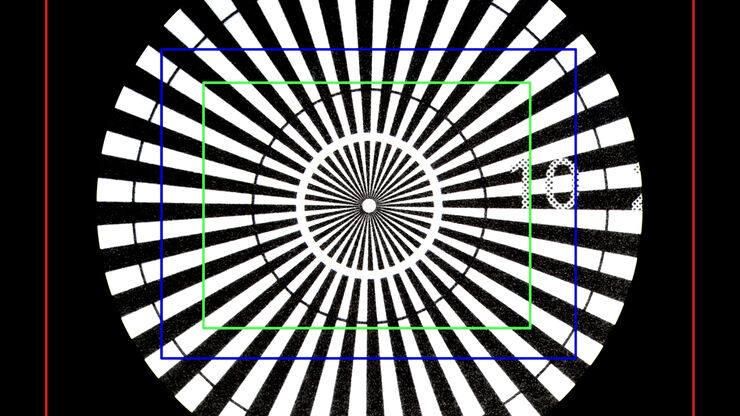

During inspection, your microscope should allow precise analysis, including comparison with reference images and standards, as well as efficient and consistent documentation. A microscope for inspection and assembly & rework should offer good 3D perception and a long working distance for sample handling under the objective. Optimal 3D perception with both high resolution and large depth of field is attained with FusionOptics.

What should you observe and document with the inspection microscope?

Leica inspection microscopes cover your needs, whether it is to have an overview of a part or component or visualize fine details. Integration with Leica cameras and the Enersight software allows for efficient, consistent analysis and documentation of results.

What is your budget for the inspection microscope?

Modular microscopes may look like a higher investment initially, but in the long run they save you money thanks to the variety of accessories making them versatile and adaptable. Due to the modularity, Leica microscopes can accommodate the needs of different types of inspection and users.

How many different people need to use the inspection microscope? How many hours will they work with it?

When using the inspection microscope for many hours, it is important to consider ergonomic accessories and modularity as they allow microscopes to be adjusted for each user helping to achieve fatigue-free work while greatly enhancing productivity. Modular designs allow configurations for individual inspection needs to increase efficiency and help maintain a high quality of work.

Find the Right Inspection Solution for You!

Dedicated configurations are available for your specific needs. Answer the short questionnaire to find the right solution for your needs. If you would rather have a representative contact you, then please click here to fill out your contact information.

Contact us{{ question.questionText }}

Please select an answer!

Best Match

{{ resultProduct.header }}

{{ resultProduct.subheader }}

{{ resultProduct.description }}

{{ resultProduct.features }}

Request Your Information Package

Why use Leica’s microscopes for Inspection?

Leica Microsystems' Inspection microscopes provide several advantages that address the aforementioned challenges.

Inspect, measure, and share with Enersight

The all-in-one integrated software solution, Enersight, can improve your routine inspection efficiency by helping you compare, measure, and share data easily. All your team members can use it intuitively to acquire images during inspection. The result is reduced need for training and less time spent supervising users doing inspection.

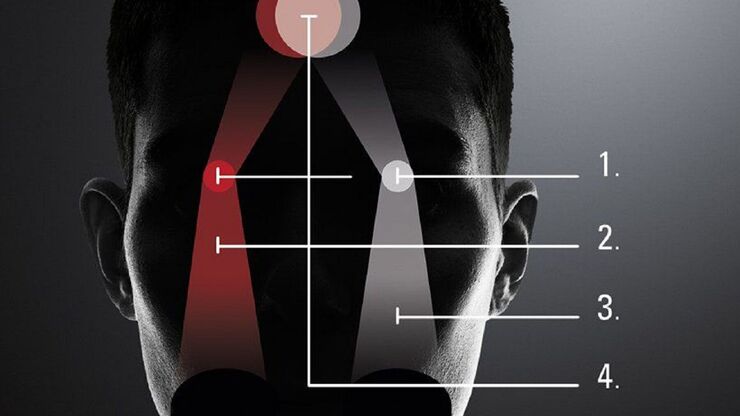

Ergonomic Design

The ergonomic design of the inspection microscopes and variety of ergonomic accessories reduces operator strain, promoting high-quality work over longer periods of time. A microscope can be seamlessly adjusted so that multiple users operate it in a comfortable way.

The right illumination for your samples

Different illumination and contrast options offered by the inspection microscope ensure that key sample features are revealed. Inspection of components and parts in different industries, such as electronics, automotive, and medical devices, can require various types of lighting and contrast.

Comparison Table

Emspira 3 | Ivesta 3 | M Series | Visoria M | |

| Sample feature of interest | Surface structure | Surface structure | Surface structure | Surface & internal structure |

| Task | Inspection | Inspection and Rework1 | Inspection and Rework1 | Inspection |

| Measurement | Yes | (Yes) | Yes | Yes |

| Ergonomics | Yes via display | Fixed 35° viewing angle | Wide range of ergonomic accessories to seamlessly fit multiple users, variable viewing angle 10°– 50° | Wide range of ergonomic accessories to seamlessly fit multiple users |

| Documentation | Yes with Enersight | Optional with Enersight | Optional with Enersight, LAS X | With Enersight |

| Digital Magnification range | 2 Up to 1027x | - | - | 3 Up to 1700x (digital version) |

| Optical Magnification range | - | 4 Up to 110x | 4 Up to 1280x | 4 Up to 3000x |

| Illumination / contrast options | Ring light, Near Vertical, Spotlight, Diffuse, Multi-contrast, Backlight | Same as to the left + Coaxial | Brightfield, Darkfield, DIC, Oblique, Polarization, Fluorescence, Incident and transmitted light methods | |

1 Rework tasks include e.g., solder joints, through-holes, connections, etc.

2 Digital magnification depends on objective used and monitor size; assumed image displayed on 28" monitor.

3 Digital magnification depends on objective used and on working distance from the 10" tablet screen while using a Flexacam i5 camera with 0.5x built-in lens and 8 mm diagonal camera sensor.

4 Optical magnifications.

The simple way in which we could reliably and accurately document our work with Emspira 3 convinced us to buy the microscope.

Our inspection work is made more efficient with Emspira 3 due to the quick start of the instrument and [...] fast zooming, focus, and image acquisition. […] Images can be directly uploaded to our network.

Frequently Asked Questions Inspection Microscopes

A Leica microscope and camera which are compatible with the microscope software allow you to share data without the need for a PC. You can directly save images on your local network and share them via email.

No, a computer is not essential to operate an inspection microscope. The microscope software, working with a compatible microscope and camera, allows you to inspect in stand-alone mode without the need for a PC. However, you can also perform inspection with a PC if desired.

The microscope software allows you to customize user-interface functions, adapting them to individual user needs. With clearly defined user roles, managers can protect the system from unwanted changes and ensure a lean user interface that supports the user skill level.

Leica microscopes are shipped in the configuration that best fits your stated inspection needs. In case your needs change later, you can always upgrade your solution by adding available accessories.

There is a wide variety of ergonomic accessories for Leica stereo microscopes. For more details, please contact your local Leica sales representative. You can also visit: Ergonomic Accessories for Stereo Microscopes

Illumination is an important factor that determines what you can see with your microscope. Here you can find an overview discussing which illumination you can use to achieve optimal inspection results: Microscope Illumination for Industrial Applications