Measurement Microscopes

Measurement microscopes are useful for determining dimensions of sample features. They are key for efficient quality control (QC), failure analysis, and research and development (R&D).

The performance of the optics, sample stage, illumination, and accessories determine the ability of the microscope to make accurate measurements at the macroscale (>0.2 mm), mesoscale (~10 µm to 0.2 mm), or microscale (~0.3 µm to 50 µm).

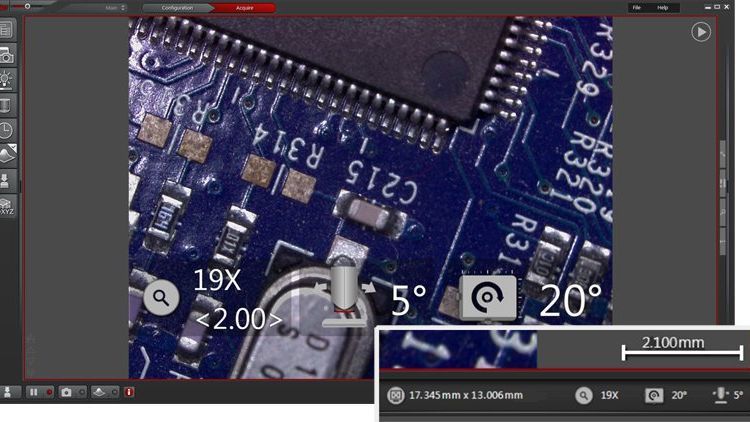

Measurements can be done manually, the old-fashioned way, with a reticle in the eyepieces. However, today many users perform measurements digitally with a microscope camera, monitor, and software. Find out more about Leica measurement microscopes below.

Contact us for expert advice on the measurement microscopes for your needs and budget.

Why use a microscope to make measurements?

Measurement of sample features and structures can be made quickly and accurately with a microscope. This ability is useful for a variety of fields like life and material science, QC, failure analysis, R&D, etc. Additionally, with digital microscopy, measurement data can be efficiently recorded and shared.

How are the sizes of sample features measured using a microscope?

In the past, the size of sample features was measured manually via the eyepieces using a reticule with a ruler. Today, the measurements are often done digitally using a microscope camera, monitor, and software.

How is resolution different from magnification?

For microscopy, resolution is the ability to distinguish sample features or structures which are close together. A higher resolution provides more resolving power and clear visualization of fine details. Magnification is the enlargement of sample structures as seen in a microscope image. It is the ratio of a structure size in the image to its actual size.

Challenges when making microscope measurements

When measuring with microscopes, there can be certain challenges:

- Optical microscopy provides mainly 2D measurements

- Measurements performed with an eyepiece reticule (non-digital) are very time-consuming and achieving accuracy is difficult

- To ensure accurate measurements, proper calibration must be done using an appropriate measurement standard

- Reliable and reproducible measurements depend on microscope performance, user experience, and defined measurement methods

- Depending on the scale required for measurements, users need to choose the correct optics with appropriate resolution, microscope camera, software, and microscope accessories

- 3D measurements are possible, but it is more time-consuming and accuracy depends strongly on magnification

- The microscope magnification with fixed optics (e.g. compound) is precisely known, but with zoom optics (e.g. stereo and digital) it may have to be determined if the optics are not encoded.

Factors to consider when measuring with a microscope

To perform accurate measurements with a microscope, several important factors need to be considered:

- Calibration: Has the calibration of the microscope been done appropriately?

- Resolution: Is the resolution or resolving power high enough to reveal the necessary details?

- Microscope optics: Are the optics corrected for chromatic and spherical aberrations as well as image flatness?

- Camera pixel resolution: Does the microscope camera have the proper pixel size and number of pixels?

Why use Leica’s microscopes for measurement?

Leica Microsystems' microscopes are designed to tackle the specific challenges mentioned above for microscopic measurements.

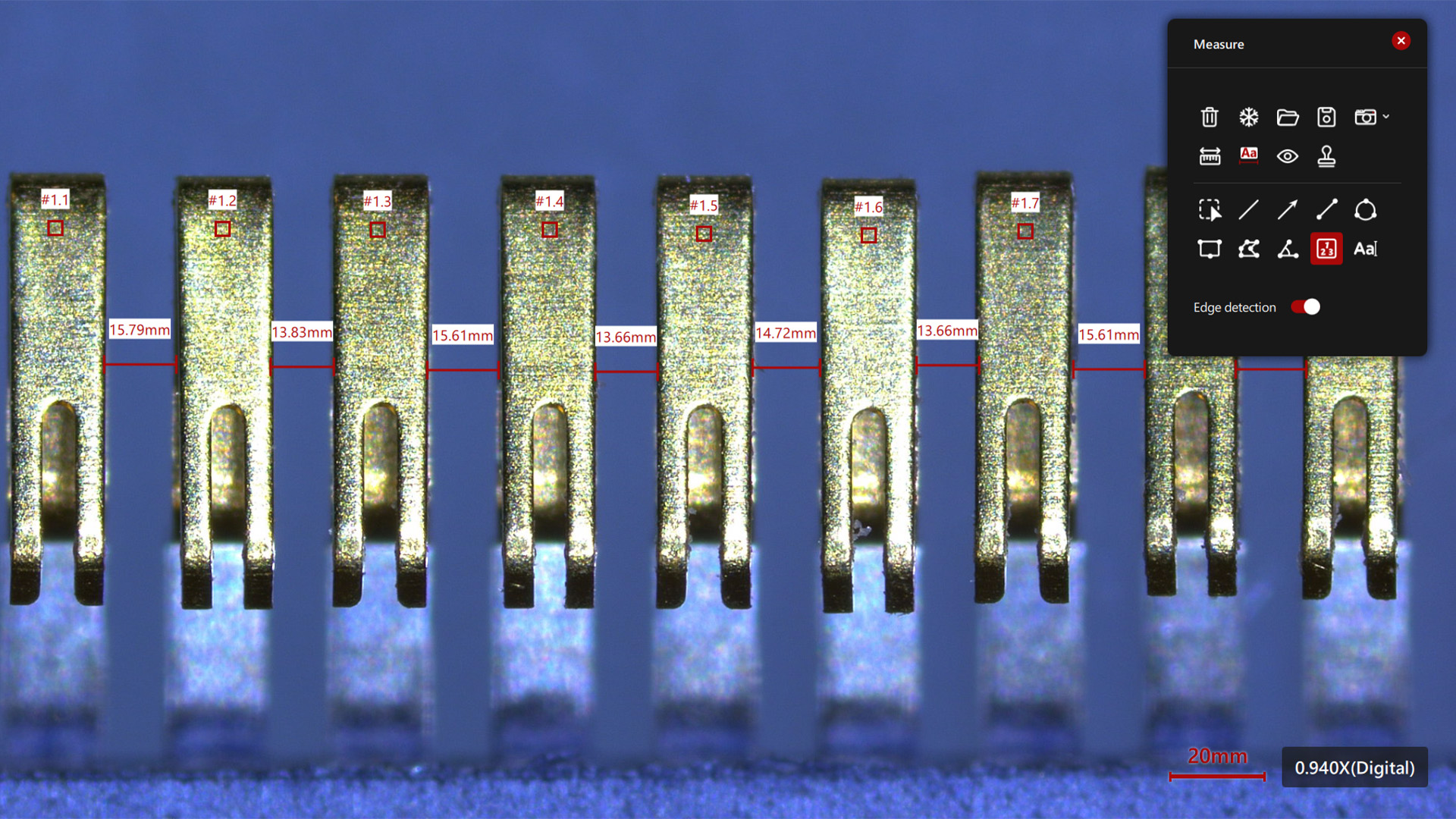

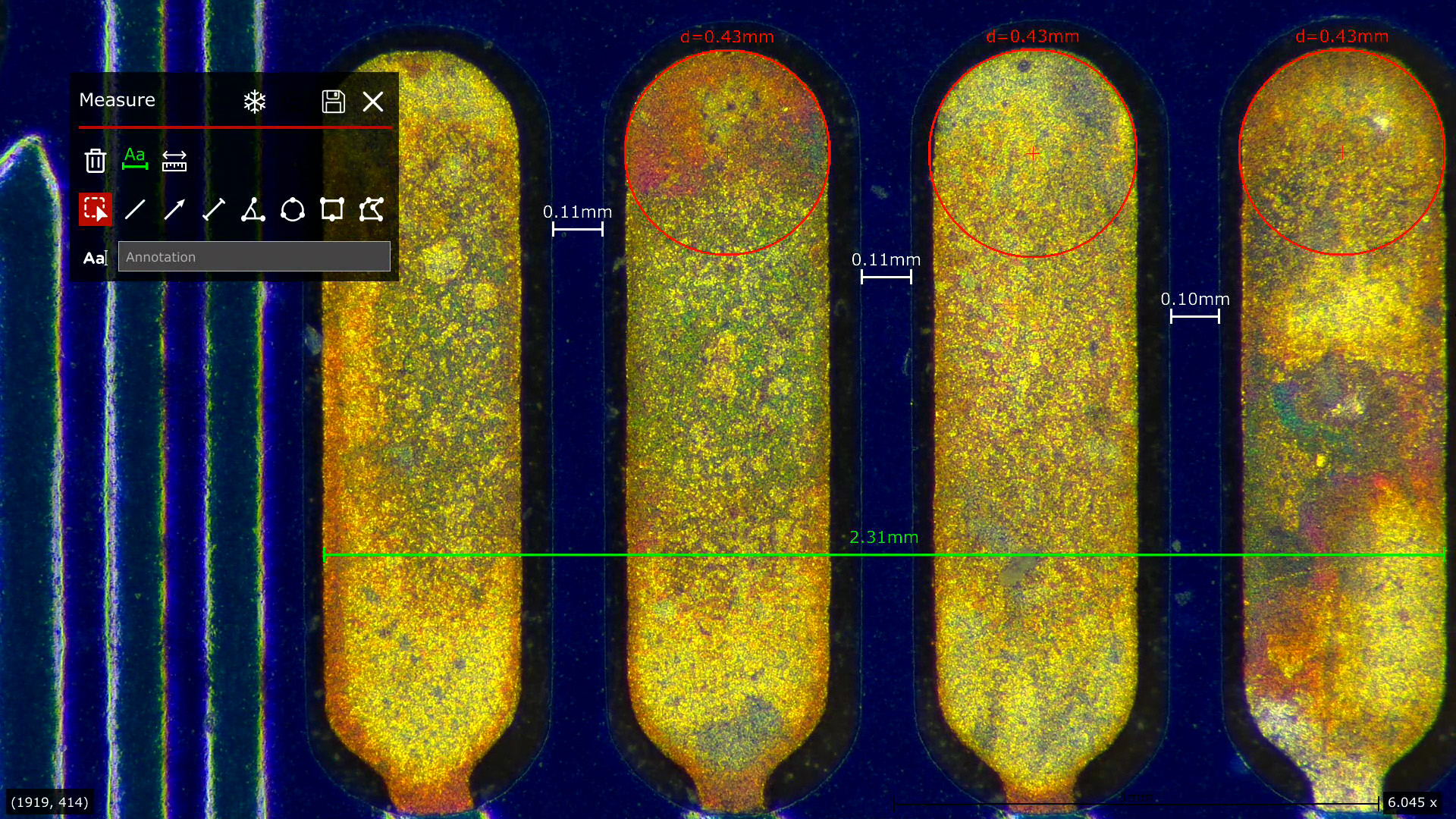

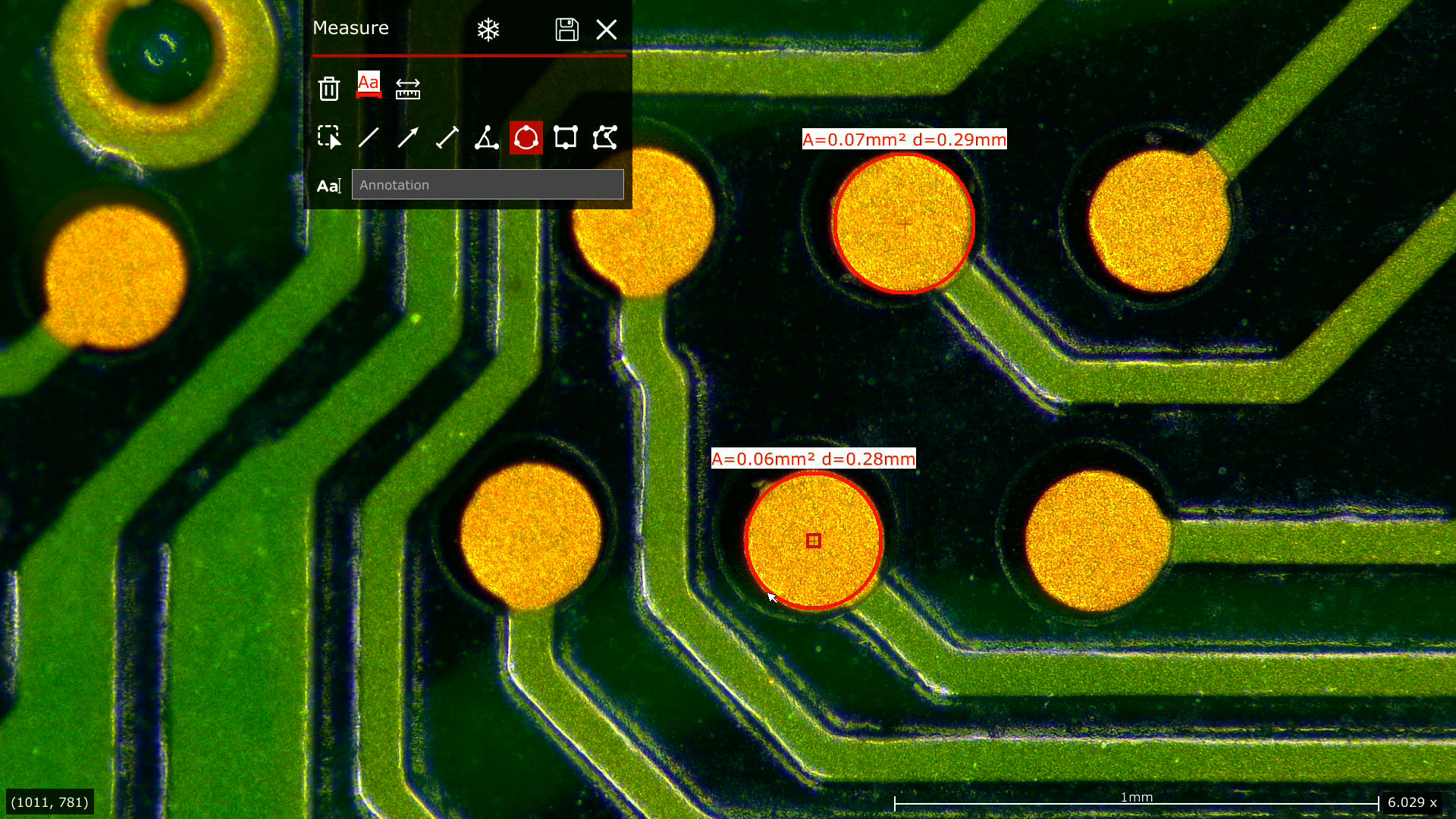

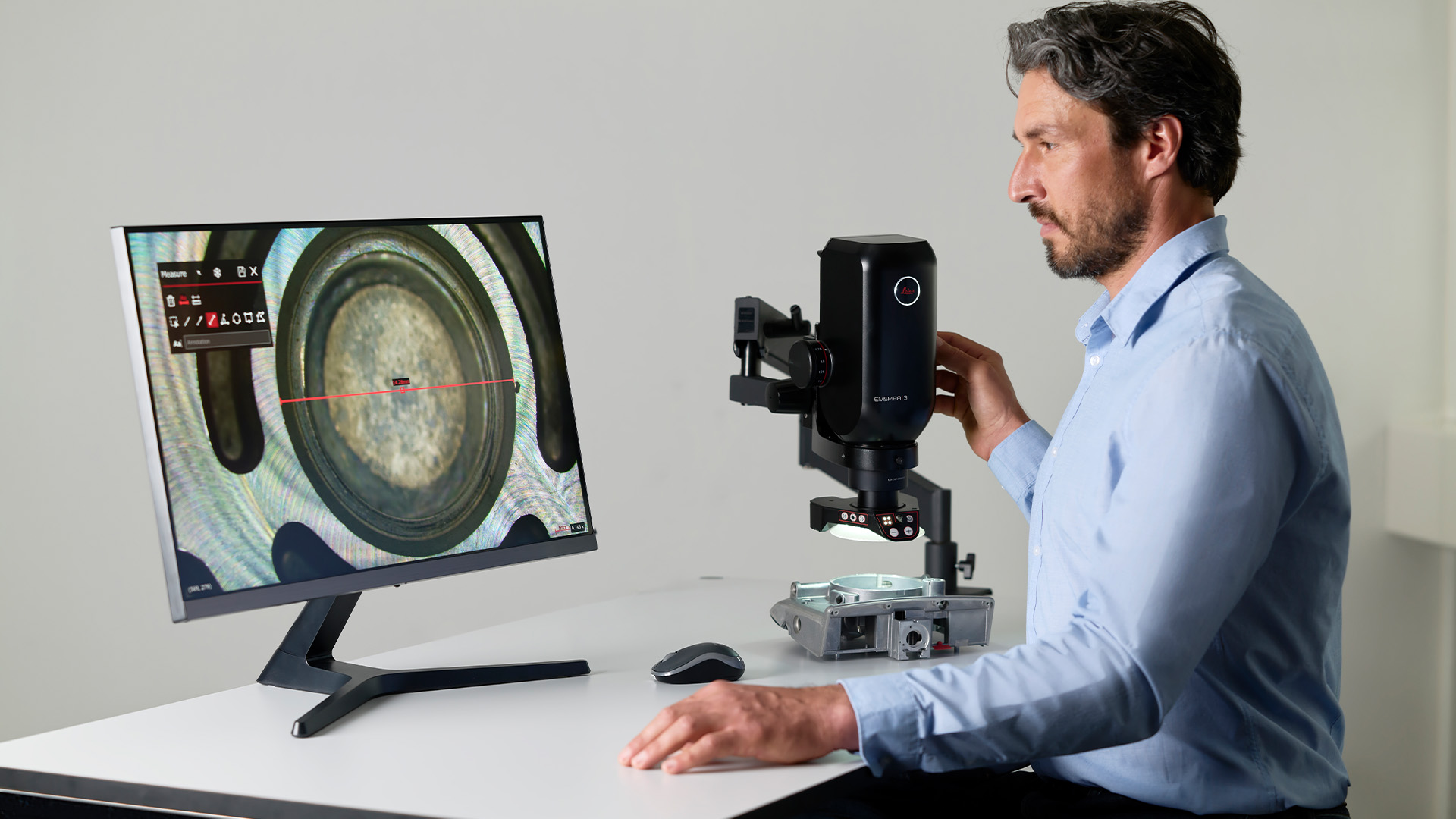

Efficient inspection and measurement

All members of your team can use the all-in-one Enersight software solution to compare, measure, and share data easily. You can make measurements directly on your monitor or mobile device during visual inspections. The measurement tools include distances between points and lines, angles, areas, etc.

Advanced analysis and documentation

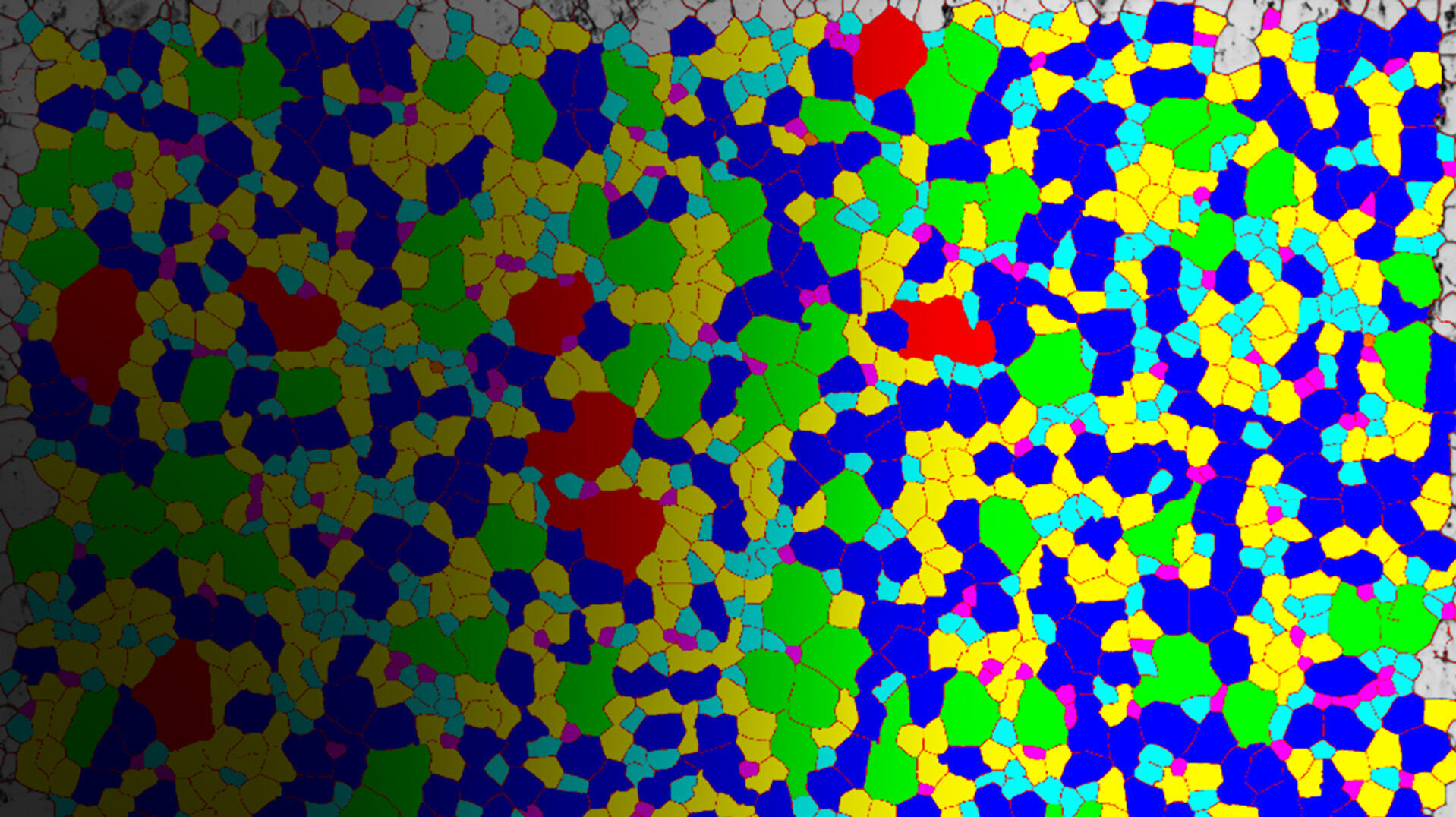

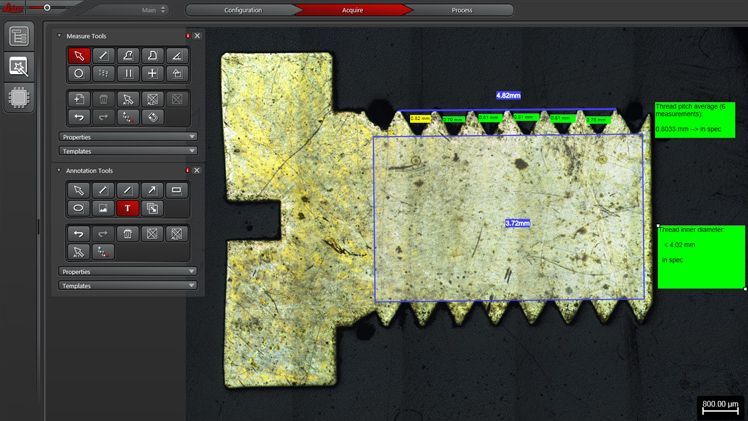

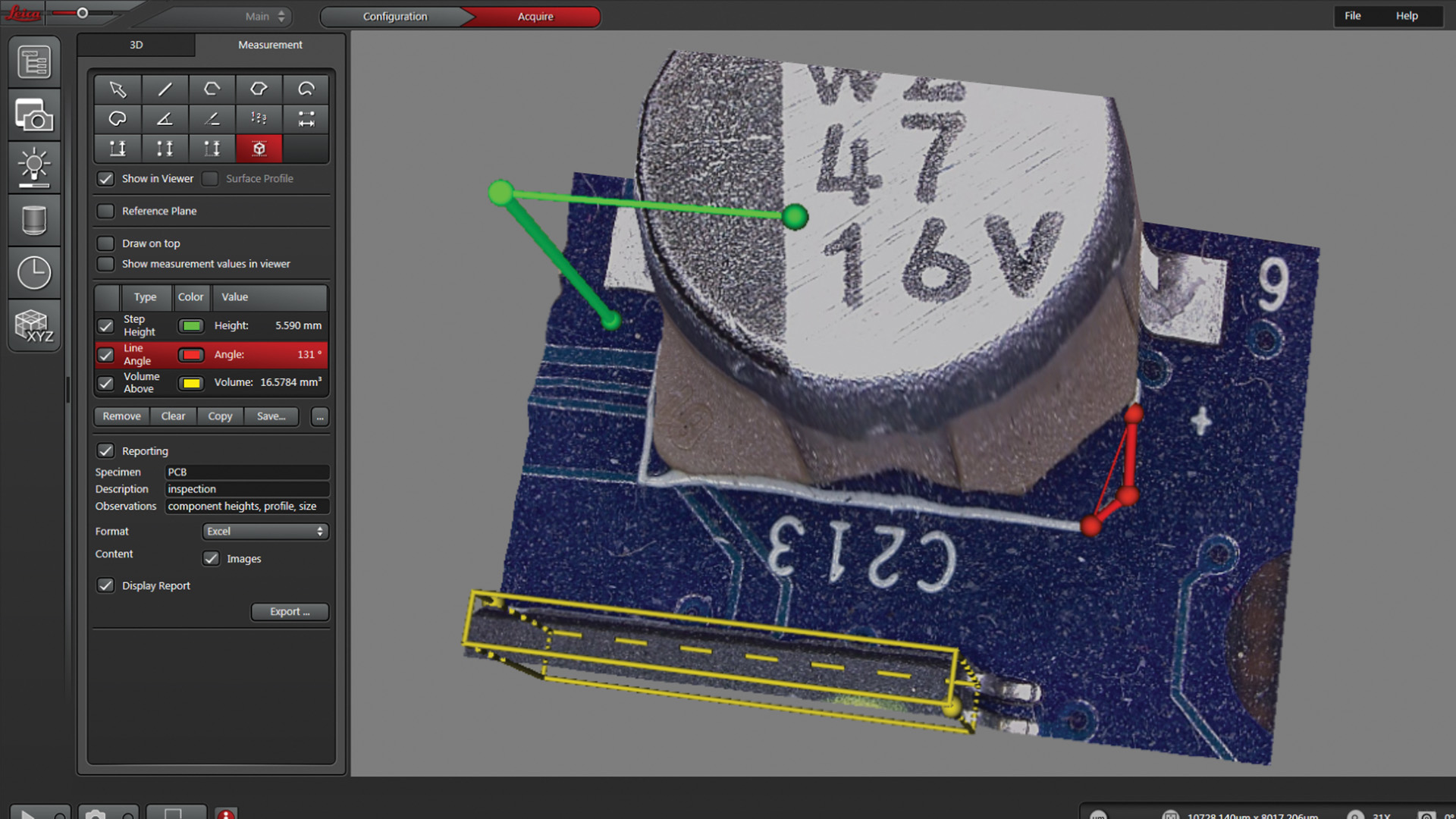

For industrial quality control and materials research, the Leica Application Suite X (LAS X) for Industry software enables rapid 3D measurements, repetitive, and automated analysis. For applications like metallography, the analysis is done in accordance with organizational, regional, and international standards.

Fast, reliable, and reproducible

For repetitive inspection tasks, like measurements, using a microscope with zoom optics, you can set an accurate zoom factor quickly and reliably thanks to encoding and knob click stops. This capability helps ensure reproducible measurements.

Comparison of measurement products & measurement software

Emspira 3 | M50/60/80 | DM2700 M | |

| Features of Interest | External structure | External structure | External & internal structure |

| Measurement during… | Inspection | Inspection and Rework | Inspection |

| Zoom / Objective turret | 8:1 zoom, Coded | Up to 8:1 zoom, Zoom steps (M50), Click stops (M60/M80) | 5-fold objective nosepiece |

| Total maximum magnification (with 2x / magn. changer) | Up to 1027x (digital) | up to 480x | Up to 2000x |

| Working distance (1x objective) | 97 mm | 90 mm (achromatic) | n/a |

| Illumination / contrast options | Ring light, Near Vertical, Spotlight, Diffuse, Multi-contrast, Backlight | Ring light, Near Vertical, Spotlight, Diffuse, Multi-contrast, Backlight, Coaxial | BF, DF, DIC, Pol, Fluo |

Enersight | LAS X | |

| Visual comparison of samples features vs. overlay, reticule | Yes | Yes |

| Routine 2D measurements | Yes | Yes |

| Routine 3D measurements | No | Yes |

| Measurements with advanced analysis (e.g. statistical trends) | No | Yes |

| Automated analysis | No | Yes |

| Automated metallographic analysis according to standards | No | Yes |

Emspira 3 allows us to rapidly make measurements and comparisons concerning dimensional outputs. For development tasks, this gives us almost instantaneous feedback and helps us save a lot of time.

Basic 2D measurements

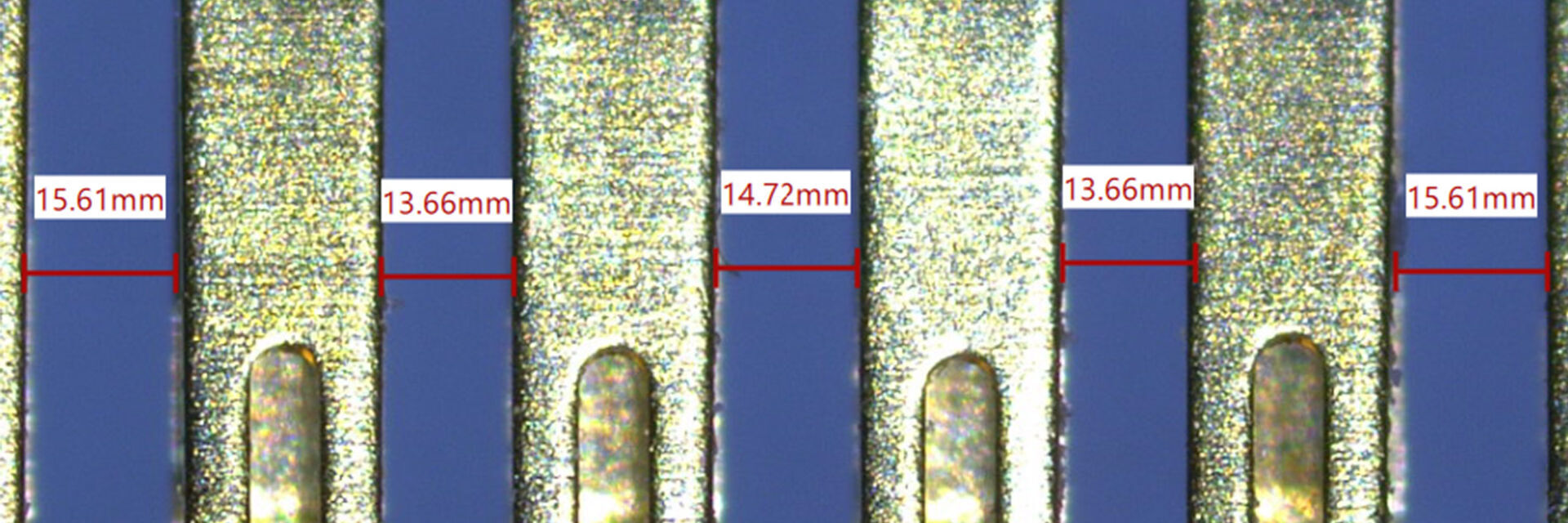

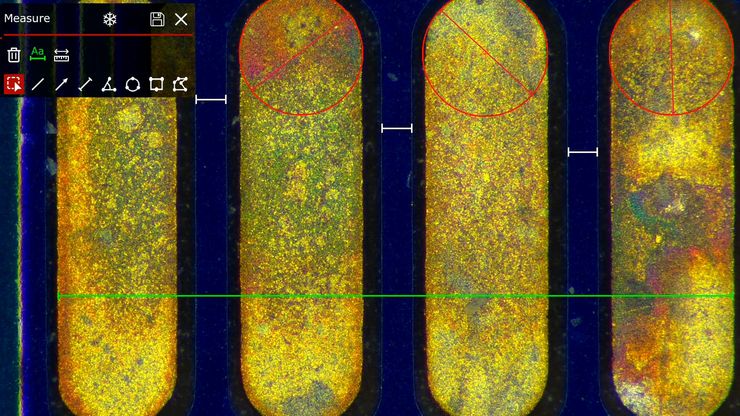

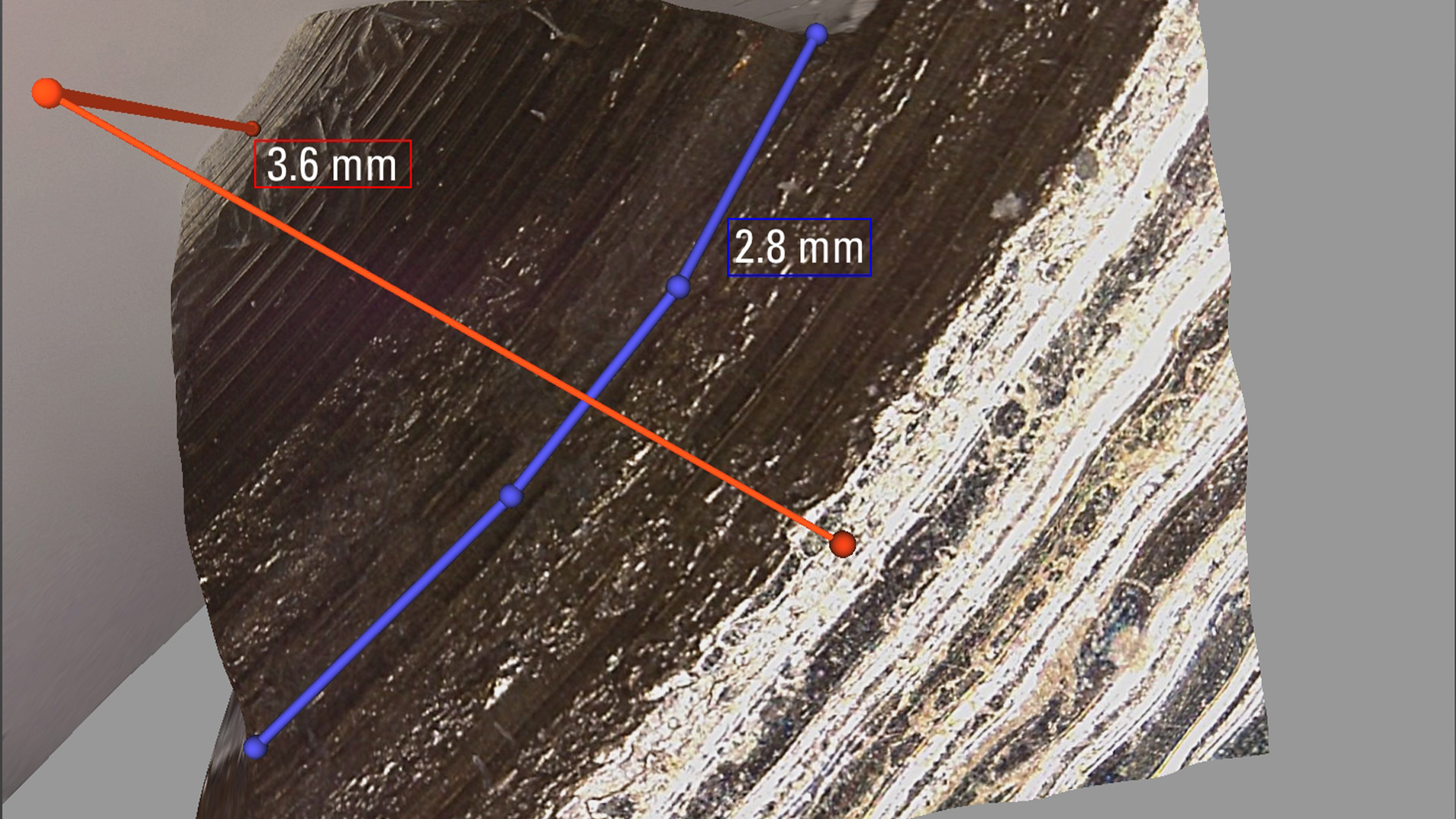

When using a microscope, basic 2D measurements can be performed using either a live or saved image.

- Distances between any points, lines, or edges of geometrical shapes.

- Areas of squares, rectangles, circles, and ellipses.

- Angles between intersecting lines.

Advanced 3D measurements

With digital microscopy even advanced 3D measurements can be performed.

- Heights of sample features, e.g. a component on an industrial part.

- Height measurement with optical microscopy requires a Z-stack of images.

- Z-stack can be recorded more precisely and easily with a motorized microscope solution.

Automated measurements

For efficiency and reliability, users can take advantage of automated measurements with the appropriate software.

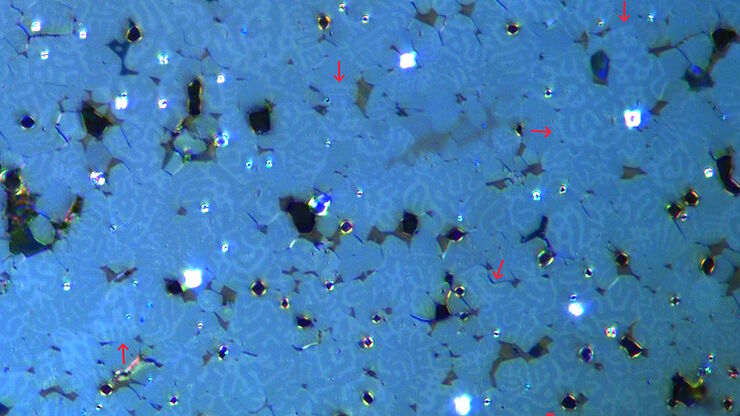

Automated measurements can be customized to users’ needs to rapidly analyze the geometrical and morphological properties of samples, i.e. features such as particles, fibers, pores, etc.

In the case of metal alloys, automated analysis of the microstructure in terms of grains and phases helps users save time.

For more examples of how automated analysis can benefit metallographic applications.

Related Articles

Frequently asked questions measurement microscopes

To calibrate a microscope with digital camera and software, use a stage micrometer or other measurement reference with a precise scale. Then follow these steps:

- Focus on the scale of the micrometer or reference

- Make a distance measurement along the scale

- Then enter the exact corresponding length value with correct units.

In order to ensure accurate microscope measurements:

- Make sure the microscope is properly calibrated

- Use high-quality optics corrected for aberrations

- Focus sharply on the sample area of interest

- Choose the proper illumination for clear visualization

- Verify that measurements are made in a way consistent with accepted norms or standards.

For digital microscopy, there are no eyepieces and the image is displayed on a monitor. For measurements, the objective is a major factor concerning resolution and magnification. At lower magnification, telecentric optics become crucial. For a microscope with zoom optics rather than fixed optics, then the zoom factor is also important.

The unit depends on the size of the sample features or structures to be measured. Common distance units are millimeters (mm), micrometers (µm), or even nanometers (nm). Common area units are mm or µm squared (mm2 or µm2). For angles, normally degrees (°) are used.

Common sources of error when measuring with a microscope are:

- Inaccurate microscope calibration

- Optical aberrations like spherical or chromatic

- Improper focusing

- Inadequate illumination

- Sample with an uneven surface

- Inconsistent ways of making measurements

- User errors.

First, the microscope should be carefully calibrated. Then, a sharply focussed image of the sample region with the feature or structure of interest using an appropriate magnification should be obtained. Different standard measurements, like lengths of structures or distances between them, areas, and angles can be performed.

Depending on the size scale, different microscopes are used. For measurements needing high accuracy at the macroscopic scale (mm or cm), then a stereo or digital microscope with a stage capable of precise horizontal and vertical movements could be used. For measurements at the microscopic scale (µm or sub-µm), then a high-performance compound or confocal microscope is a possible solution.