Automotive & Aerospace Microscopy Solutions

The automotive and aerospace industry relies on microscopy imaging solutions for quality control, failure analysis and innovation. Leica products provide insights into materials and components used in automotive and aerospace, as well as other transportation sectors like railway and shipbuilding.

Our imaging and inspection solutions help you to meet your current and future needs in automotive and aerospace production – allowing you to concentrate on innovation and remain competitive.

Please contact us for personal advice on microscopy solutions for automotive and aerospace.

Select your field of application

How are optical microscopes used in quality control?

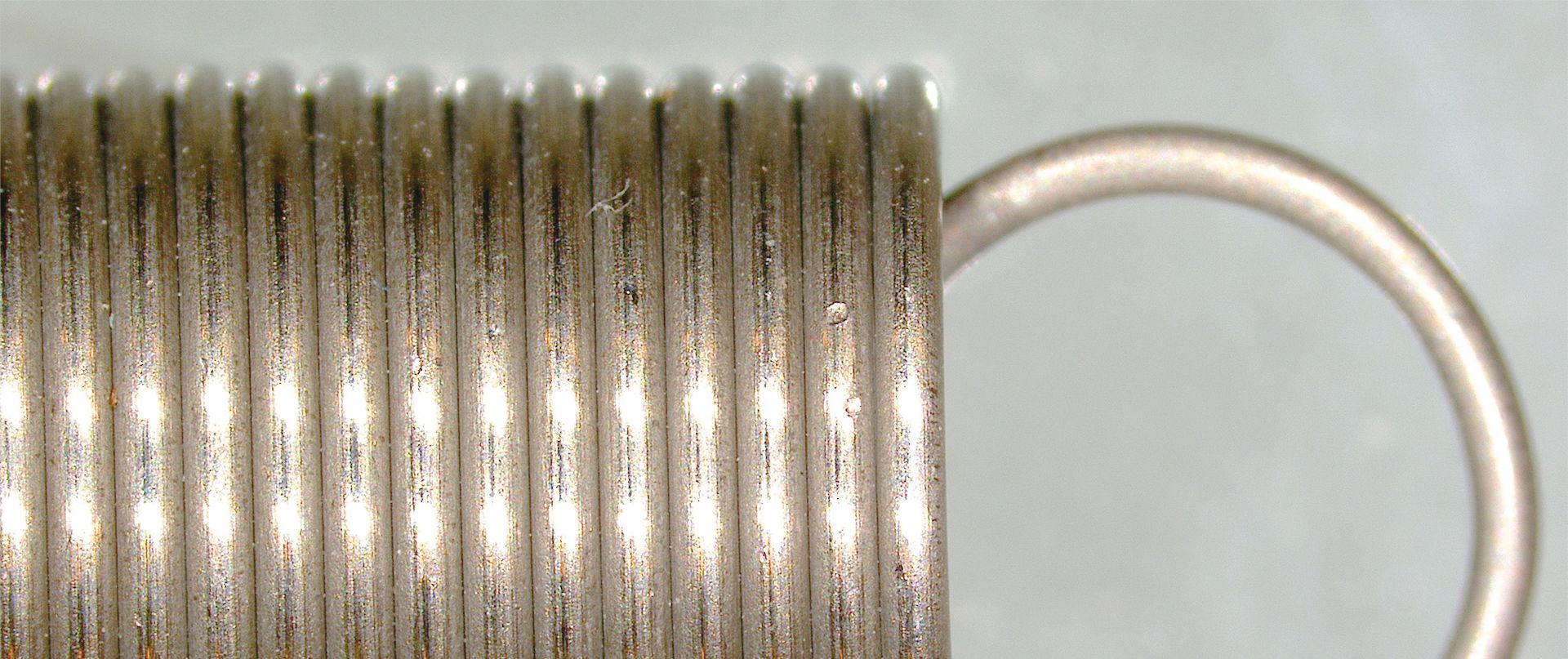

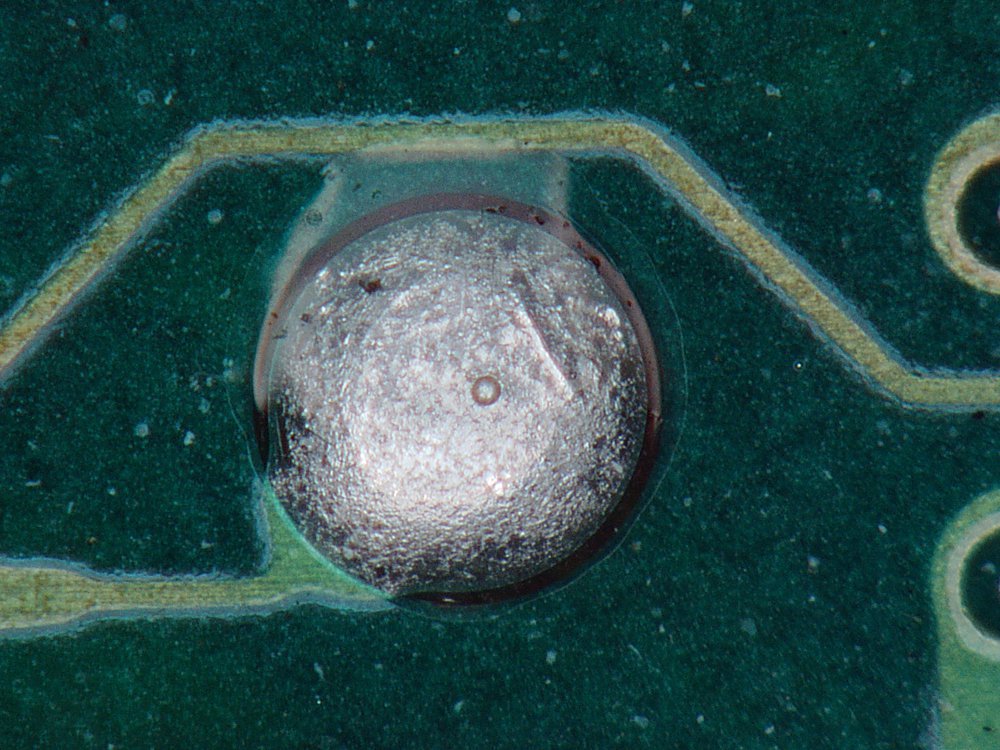

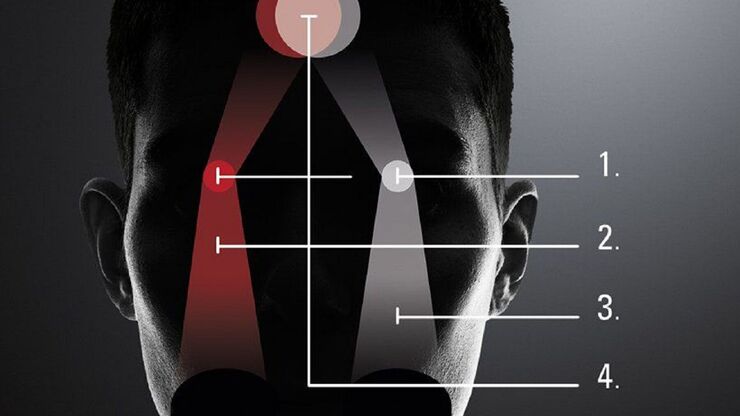

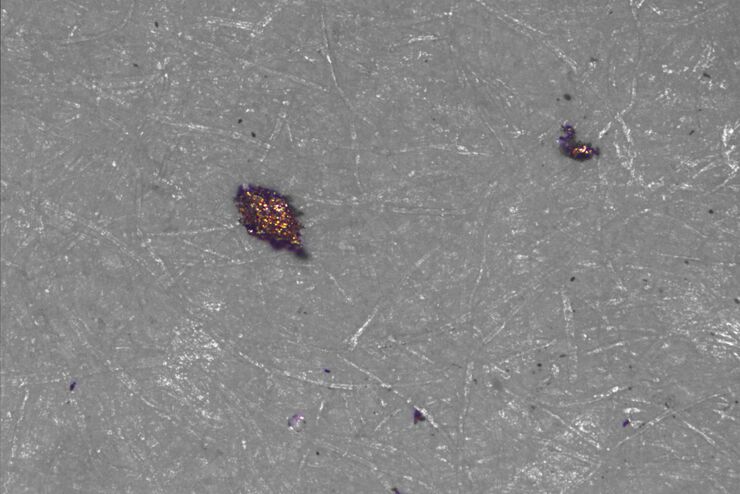

In quality control for automotive and aerospace, defects like cracks and impurities can lead to catastrophic failures. However, inspection of hard-to-see details is often challenging due to reflections, cavities, varying heights or different focal planes.

Leica microscopes offer high-resolution analysis of the microstructure and layers to detect defects. With the right illumination and contrast settings, they can also be optimized for a great variety of sample types.

Can we improve compliance with automotive standards?

Meeting industry guidelines and standards are important for all transportation segments in order to secure the safety, reliability, and performance of materials and components, especially when operating under high stress or extreme environmental conditions.

Leica solutions help ensure compliance with manufacturing guidelines and standards by enabling precise analysis of material properties and microstructure and detection of defects.

Can documentation and reporting be made easier?

Accurate documentation is necessary for audits and quality assurance along the value chain. Consistent, traceable records are often required to support quality assurance for automotive and aerospace manufacturing processes.

Leica solutions facilitate comprehensive reporting and documentation features which aid in maintaining thorough records during the inspection process.

Why use Leica microscopes for automotive and aerospace sectors?

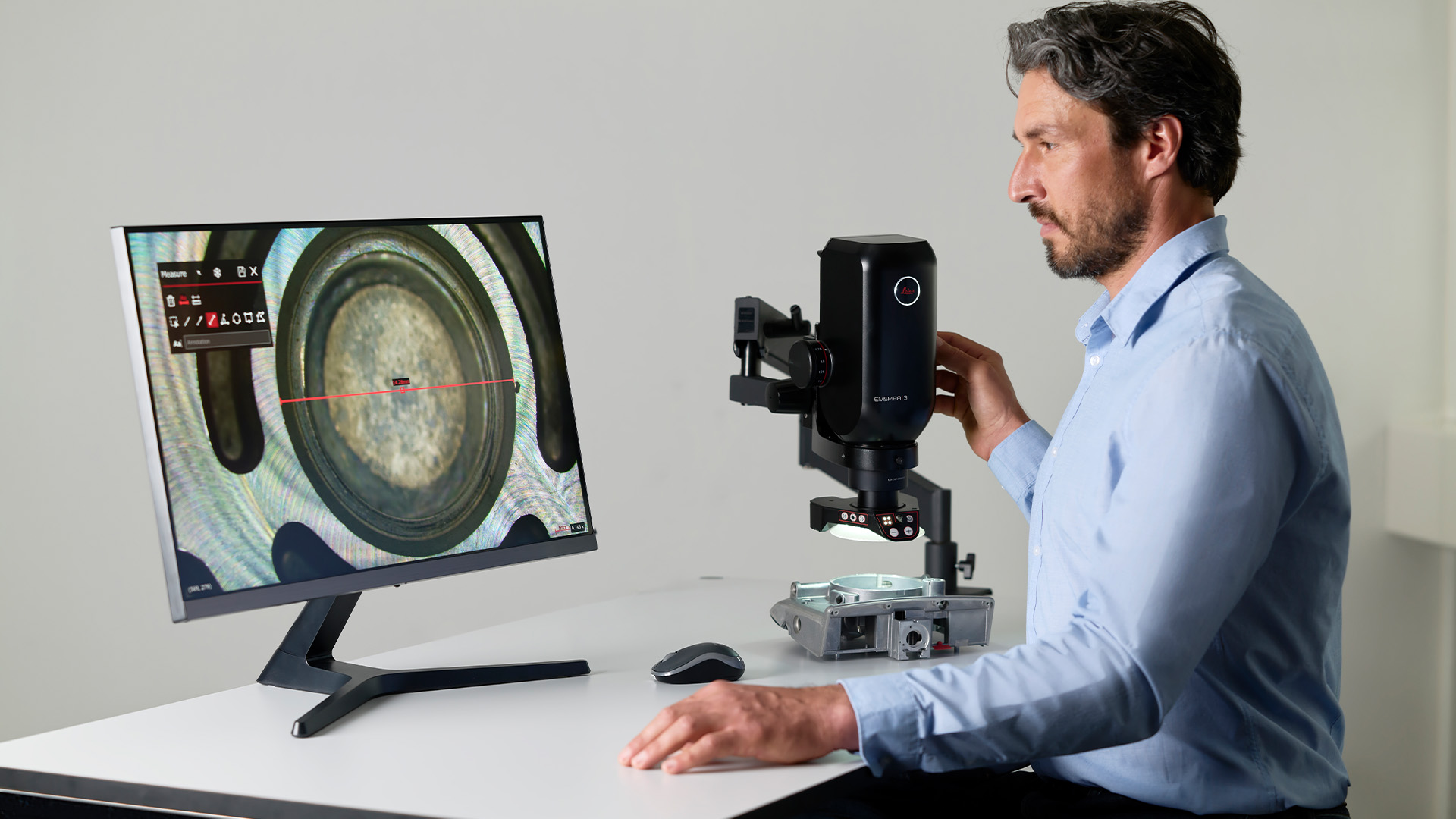

Leica Microsystems' microscopes provide high-resolution imaging, which is essential for detailed analysis and offer several advantages that address the challenges in the automotive and aerospace sectors.

Tailored to sample types

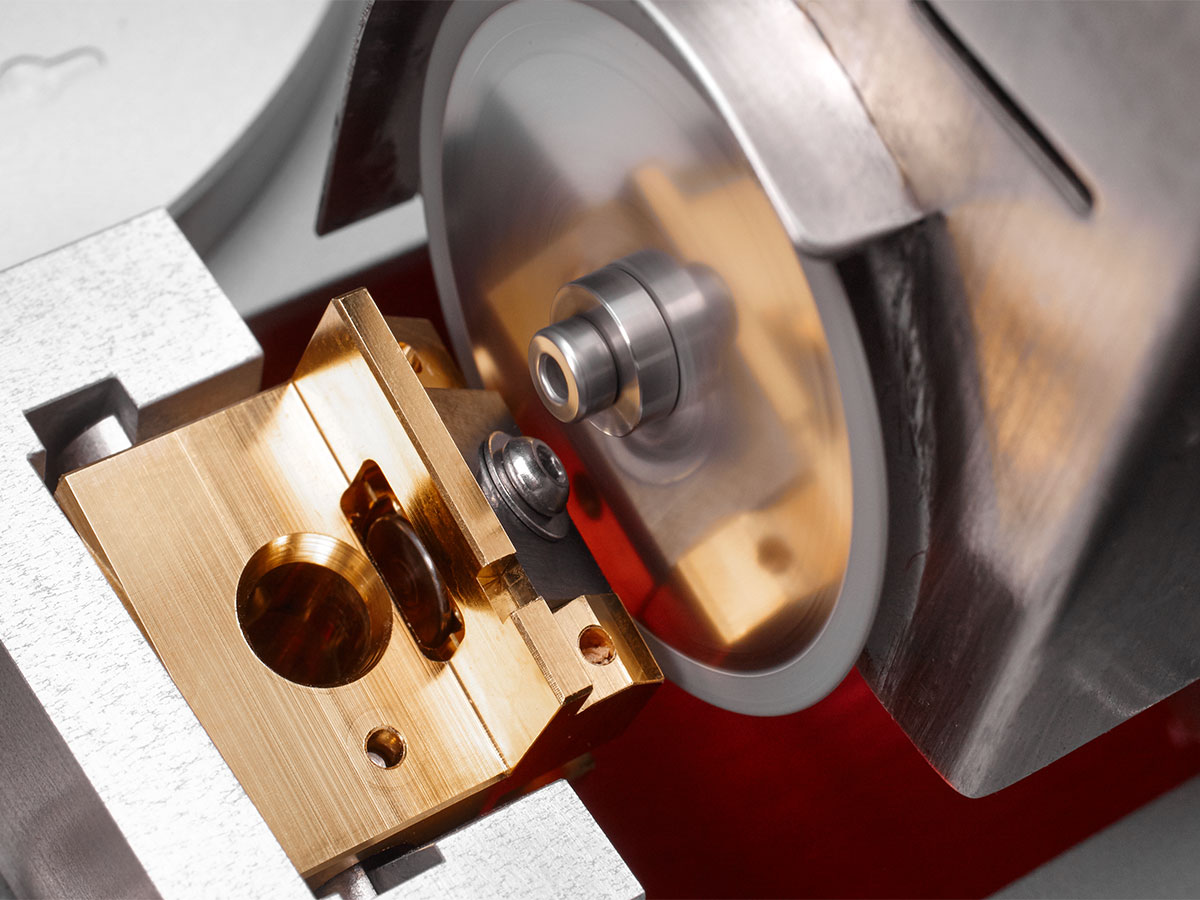

Leica microscopes are highly versatile with an extensive range of illumination and contrast options, such as BF, DF, Pol, DIC, UV and oblique. This range of configurations allows them to be used across various applications and sample types, from material science to component inspection, and ensures that key features can be seen in detail.

Agreement with standards & norms

Leica solutions comply with relevant standards and norms used in the automotive and aerospace industries, such as VDA19, ISO16232, ASTM E112, ASTM E45 or ISO 4967. You can choose dedicated solutions for technical cleanliness as well as particle counting for hydraulic fluids. For metallographic analysis, a full range of solutions from manual to motorized are offered.

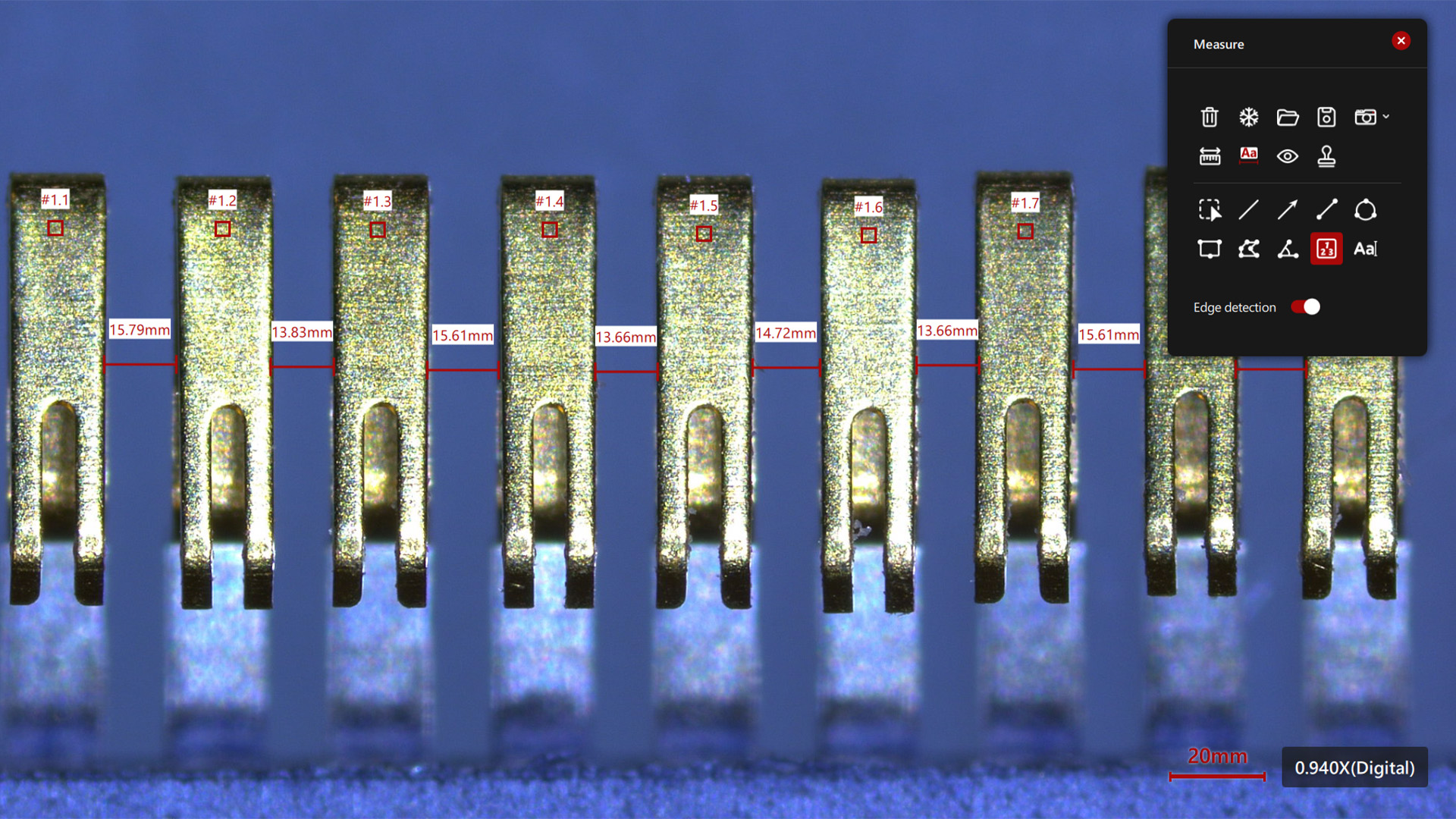

Easy-to-use documentation software

The Enersight software is designed to support routine inspections and offers integrated documentation and sharing capabilities. In addition, LAS X Expert modules offer advanced automation features to reduce human error and increase productivity, even for complex tasks.

We chose an instrument from Leica Microsystems, because with all other microscope suppliers the instrument operation was much more complicated.

Automotive & Aerospace

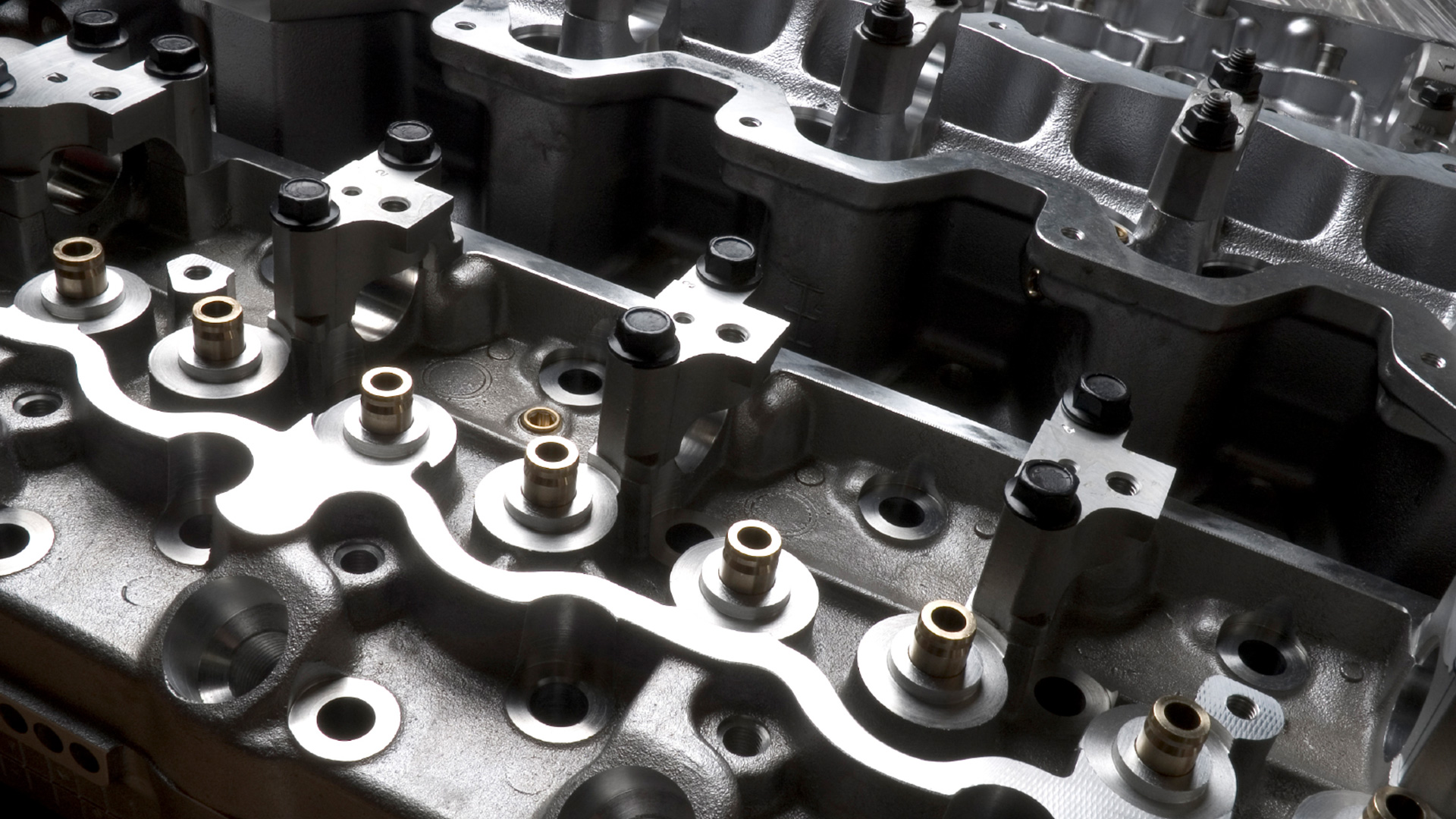

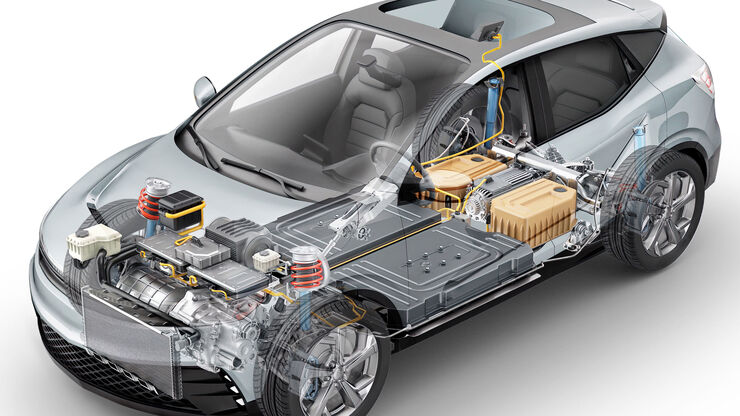

In the automotive sector, microscopy is widely used for inspecting engine and power train parts or electronic components along the value chain. Applications encompass inspection including 2D and 3D measurement, metallographic analysis, and technical cleanliness.

Leica imaging solutions capture important details

Using our optics, you can reproduce faithfully the part’s or sample’s true colors with good resolution and rich contrast. The performance of our imaging solutions and optical measurement systems help you to reliably achieve the targeted performance.

Applications in automotive industry

- Inspection of parts

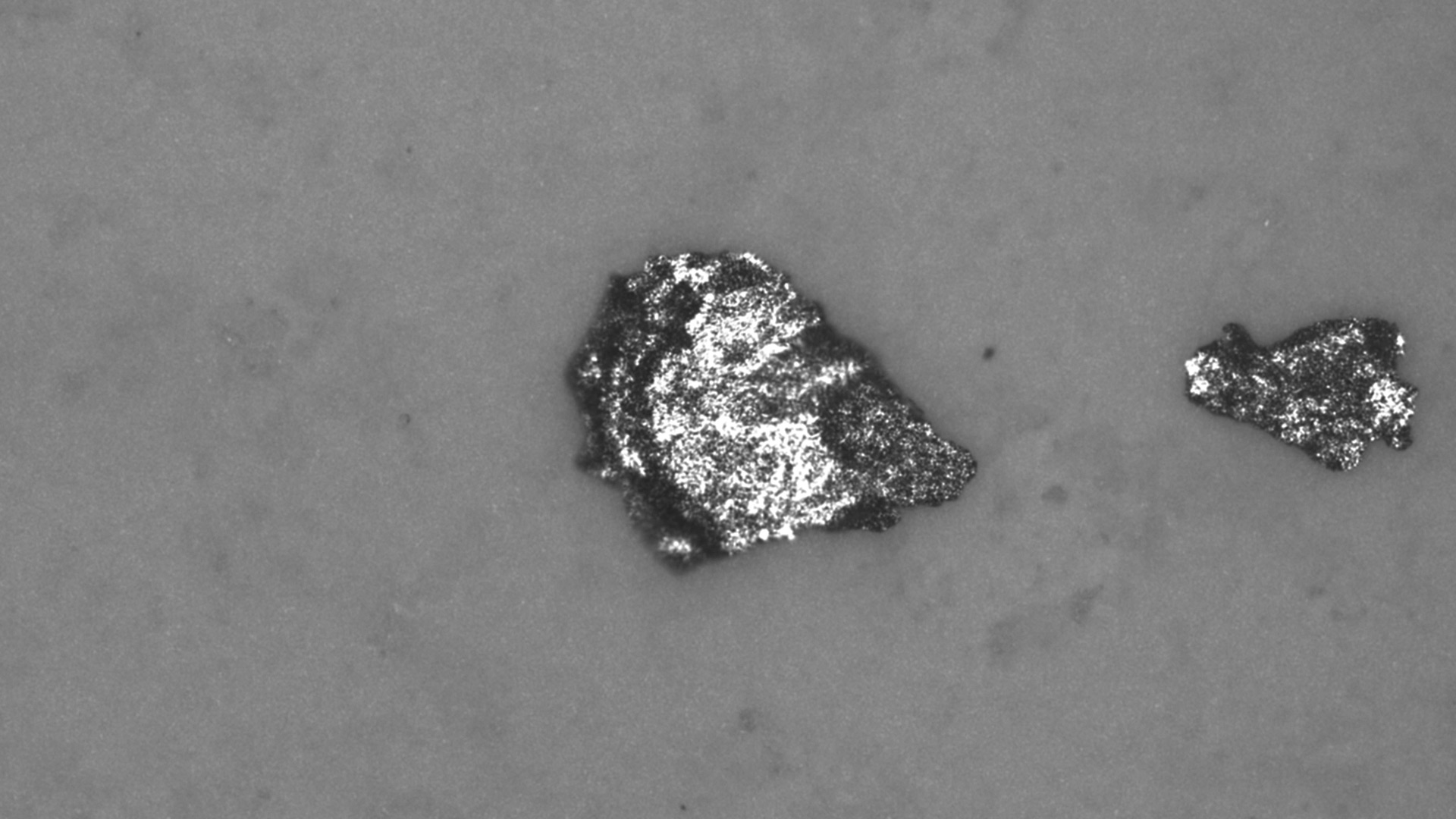

- Determination of engine component cleanliness

- Evaluation of steel alloy inclusion rates.

Image quality is always crucial for these applications, because if you do not detect something important, then it may cause trouble.

Confidence in image results

Leica imaging solutions deliver reliable data and results, giving you peace of mind during data acquistion and analysis.

You must have confidence in your imaging data and measurement results, otherwise the conclusions may be doubtful.

Innovative technologies in automotive industry

The implementation of more innovative technologies in automobiles has required more electronics and electrical interconnections. As a result, inspection of auto electronic parts has steadily grown.

Aerospace

In the aerospace industry, microscopes play an essential role in safeguarding the integrity of critical components. Microscopes can be used for material analysis, metallography for materials such as special alloys, coatings, composite materials, or turbine blades, and examining critical electronic components through inspection and measurement.

Electric Vehicle and Batteries

Batteries are key for the successful transformation from the internal combustion engine to electric vehicles (EVs). For R&D and reliable manufacturing, microscopes play an important role for electrode and burr inspection, cross-section analysis, as well as cleanliness analysis.

Analyze and report results easily, no matter the expertise level

Our encoded microscopes are smart imaging solutions which will ensure that you and every one in your team will meet documentation standards, like ISO 16232 or VDA 19, on the fly.

Meet documentation standards

The auto-storing of all relevant parameters with the image every time, in part, enables you to achieve this goal. All your reports will include reliable data and, whenever needed, the stored parameters can be recalled for review and verification of the results.

Railway and Shipbuilding

For railway and shipbuilding, microscopy helps in analyzing the integrity of marine building materials. Applications include the inspection of propulsion components and metallographic analysis of weld seams and structural alloy components to prevent failures and enhance safety.

See more details with versatile illumination

We offer you imaging systems that allow you to see with less effort difficult-to-image details, due to the versatile illumination and high quality optics.

Stay focused on innovation

For you to stay focused on innovation, efficient, reliable inspection and evaluation of auto parts is a sginificant advantage. Inspection, quality control, and failure analysis often require imaging solutions where the illumination mode, lighting intensity and angle, influences dramatically the detail seen.

Frequently asked questions Automotive & Aerospace

Common optical microscopes in the automotive industry include upright microscopes for surface analysis, inverted microscopes for heavy sample inspection, stereo microscopes for 3D inspection, and digital microscopes for high-resolution imaging, documentation, and automated analysis.

Microscopy in transportation manufacturing ensures material quality, analyzes coatings, and detects microstructural defects in metals, composites, and alloys. Applications include failure analysis, weld inspections, contamination detection, and evaluating wear-resistant coatings across passenger and commercial vehicles, aerospace, railway, and shipbuilding, ensuring safety, reliability, and performance in critical applications.

Microscopy for quality control in automotive enhances safety by detecting material defects, analyzing microstructures and conducting failure analysis. This ensures materials and components meet stringent manufacturing safety standards and will perform reliably, even under extreme conditions.

Microscopy for quality control in aerospace checks the quality of materials, detects microstructural defects, and verifies coatings on materials. It aids in failure analysis, weld inspection, and composite analysis. Microscopy helps to ensure lightweight but safe construction in adherence to strict safety industry standards.

Optical microscopy in aerospace faces common challenges like complex sample preparation for the high-resolution imaging and analysis of parts. Industry experts need to ensure accurate and repeatable results under strict industry standards, and must also be able to interpret the data to assess safety and material performance effectively.

Leica microscopes can analyze a variety of components, including engine parts and components, electronic circuits, composite materials, and structural welds.

Yes, Leica microscopes are highly versatile and designed to meet the needs of both research & development (R&D) and failure analysis in laboratories as well as quality control (QC) close to the production line (at-line) or off-line.

Leica solutions allow users to work with a wide range of guidelines and standards for technical cleanliness or metallographic analysis, such as VDA19, ISO16232, ASTM E112, EN10247, ASTM E45 or ISO 4967. A list of supported standards is available on these application pages: Technical Cleanliness and Metallography.

Leica microscopy solutions include cameras and software which can be used for immediate image documentation with annotations made during the inspection process. For technical cleanliness or metallographic analysis, a full report is automatically generated, in accordance with international standards and norms.