Metal Industry Microscopy Solutions

The metal industries mine, produce, and process ferrous and non-ferrous metals for alloys, such as iron and steel, aluminum, copper, titanium, magnesium, cobalt, nickel, lead, and zinc. They also produce precious metals like gold, silver, and platinum. Over the years, metal recycling plays an always-increasing important role.

To ensure that customers from metalworking industries, such as automotive and transportation, electronics, or construction, receive high-quality materials, microscopy plays an important role along the value chain. Inspection microscopes play a crucial role in assessment, quality control, failure analysis, as well as research and development.

Please contact us if you would like to have personal expert advice on our microscopy solutions for metal industries.

Select your field of application

Assess

Find out which mineralogical samples you have via qualitative compositional assessment of cross sections, before you go through the trouble and expense of detailed quantitative chemical analysis.

Evaluate

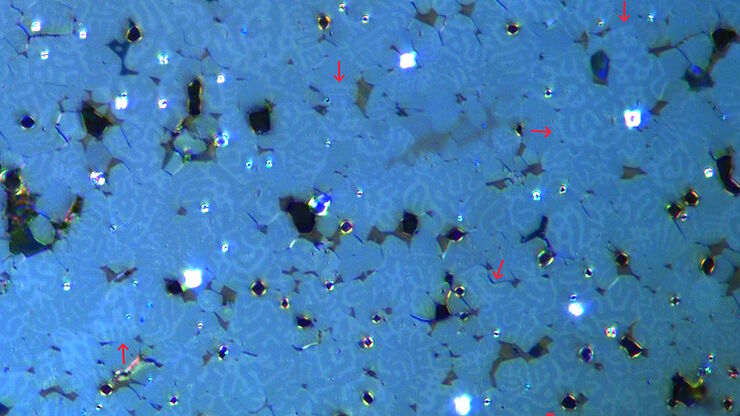

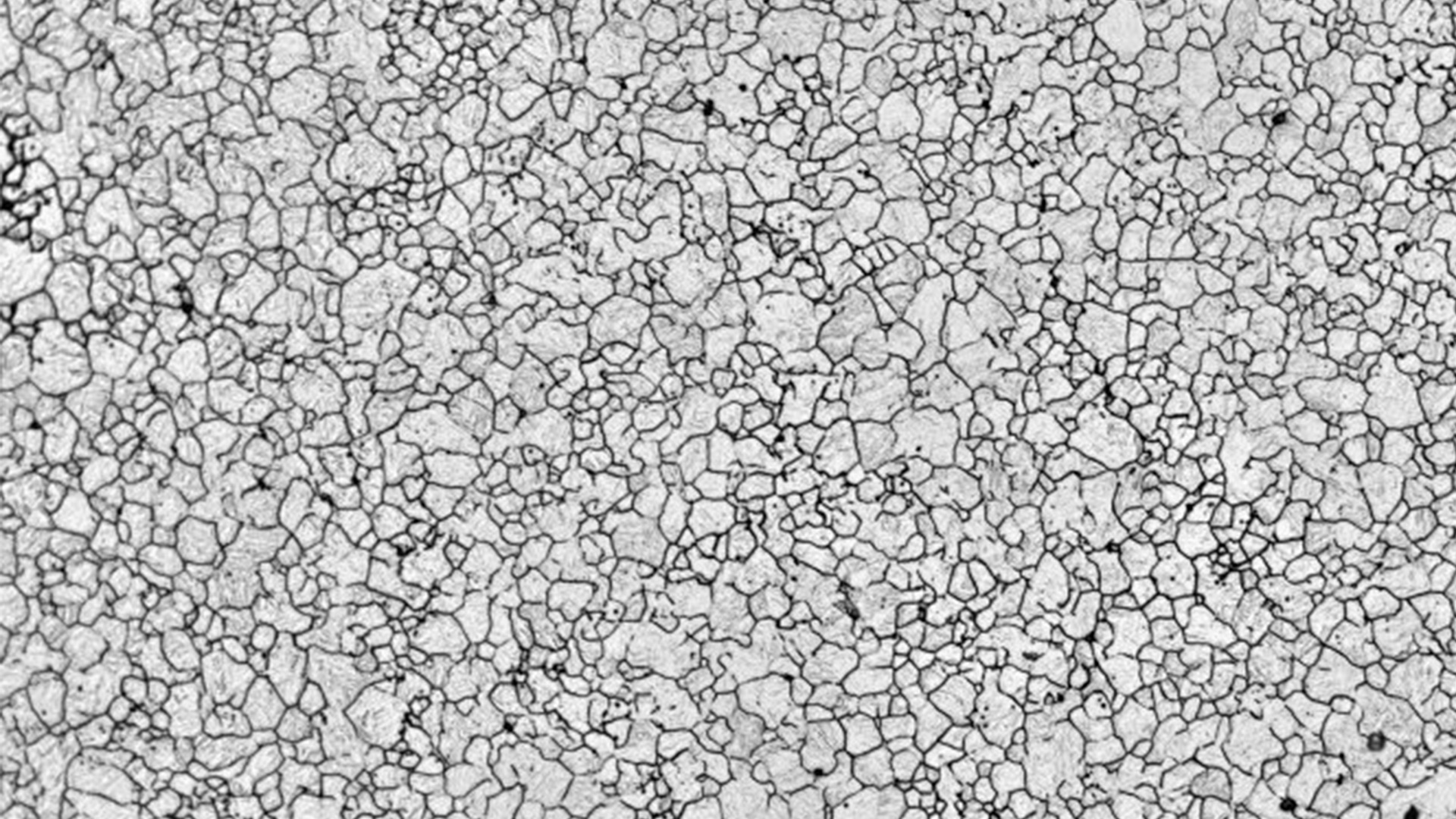

Evaluate your samples quantitatively to ascertain purity, non-metallic inclusions, grain size, phases, and microstructure components. More information

Inspect

Inspect metals and alloys during production and testing for quality assurance and failure analysis.

Document

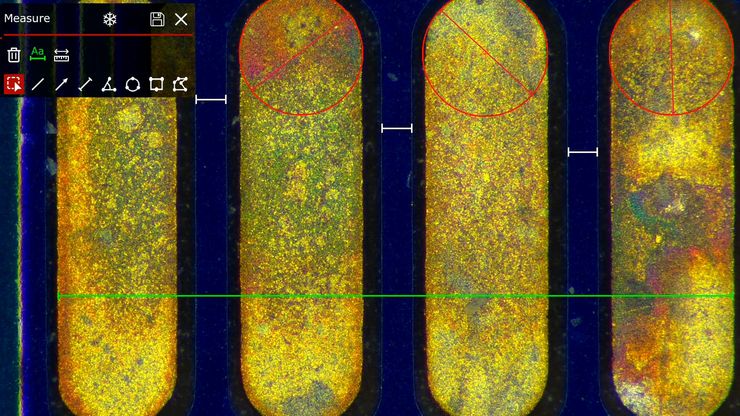

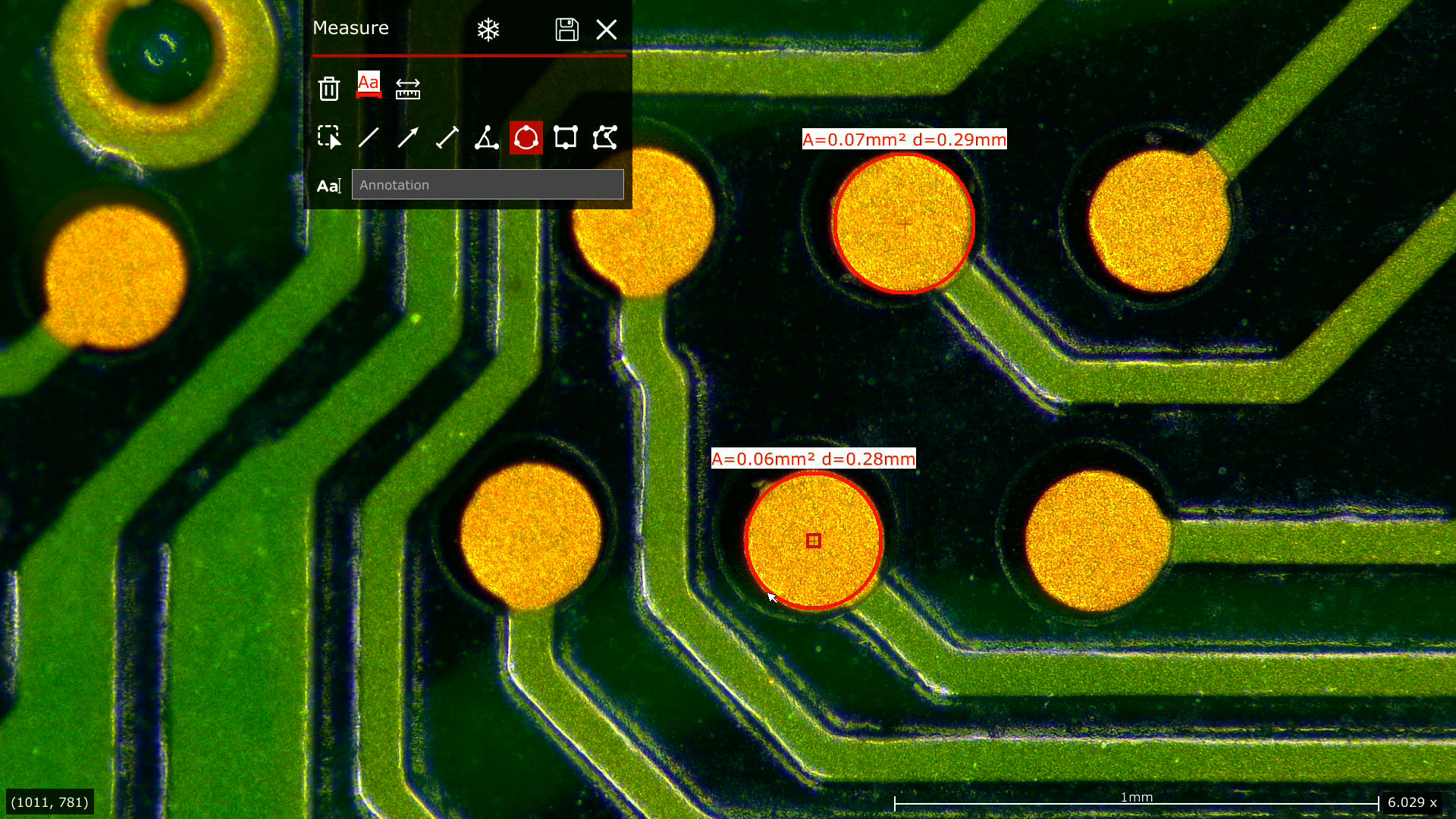

Document every step of your tasks, including measurements and annotations, to confirm that metals and alloys adhere to quality standards relevant for customer requirements and regulatory affairs.

Workflow efficiency

Metals and metal alloys need to meet customer expectations both in terms of quality and price. Therefore, time is of the essence for all microscopy tasks. The more smoothly microscope systems can be operated, the more time can be saved. Leica Microsystems designs its microscopes, cameras, and software with this demand for efficiency in mind, so that all steps of a workflow require as little effort as possible.

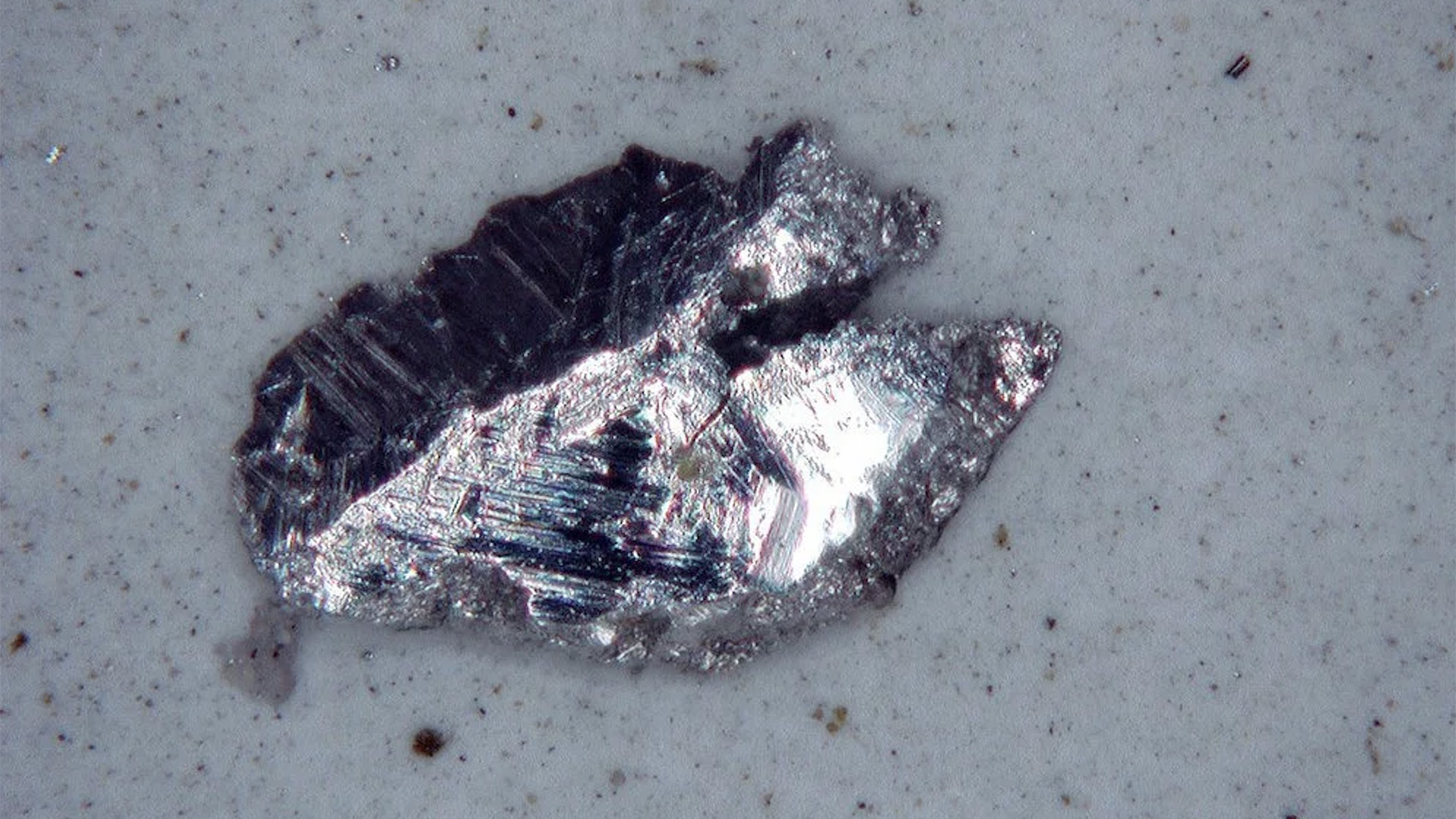

Mining

For mining, microscopy helps you assess quickly which materials a drill core contains. Depending on the information, you may decide whether it’s worth mining at a specific place.

Digital microscopes, such as the Emspira 3, help users inspect samples fast and obtain a quick overview. For more insights, a polarization microscope like the DM2700 P reveals more details.

Metal alloy development

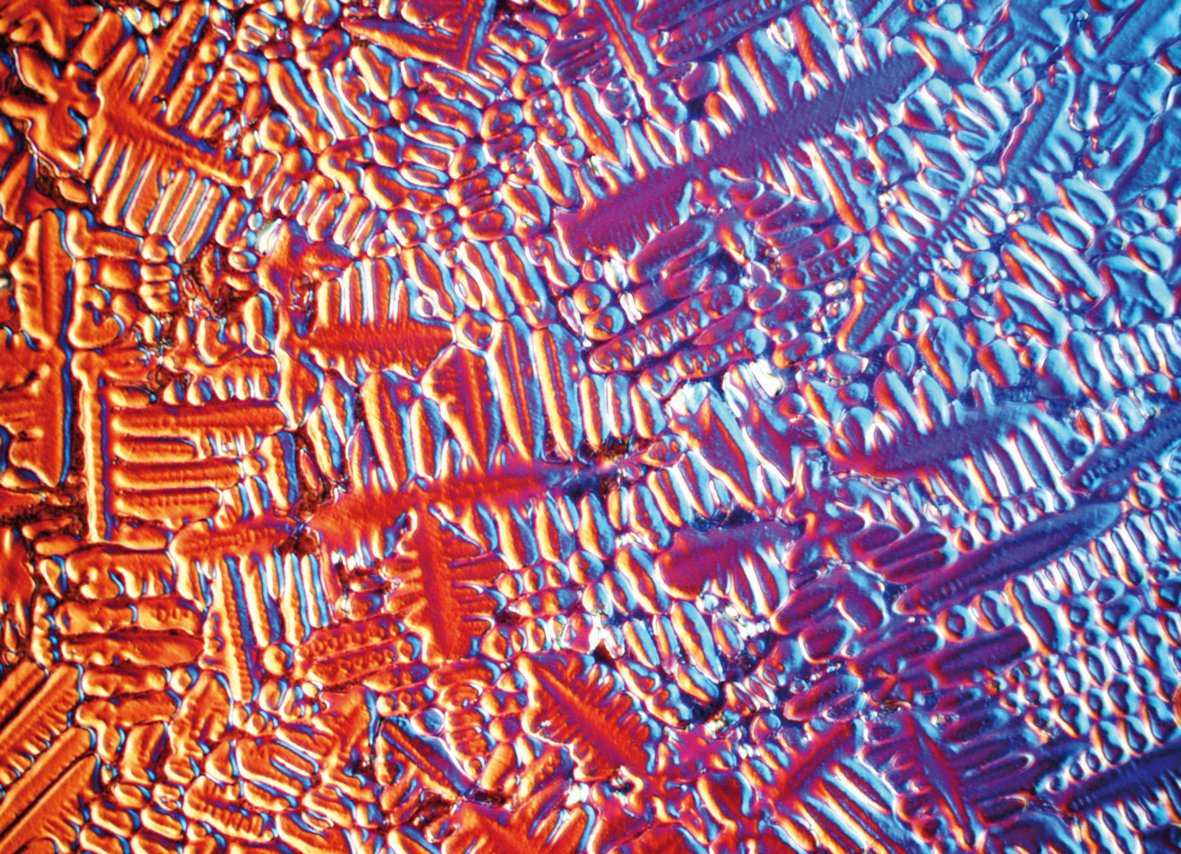

Metal alloys are essential for most metal-working industries. While thousands of standard metal alloys, such as steel or brass, are in use today, new ones with better performance are being developed regularly. For research and development, you rely on microscopy for characterization of alloy microstructure, i.e., grains, phases, and inclusions.

Upright or inverted material microscopes, such as the DM6 M or DMi8 A, are helpful tools for metal alloy development.

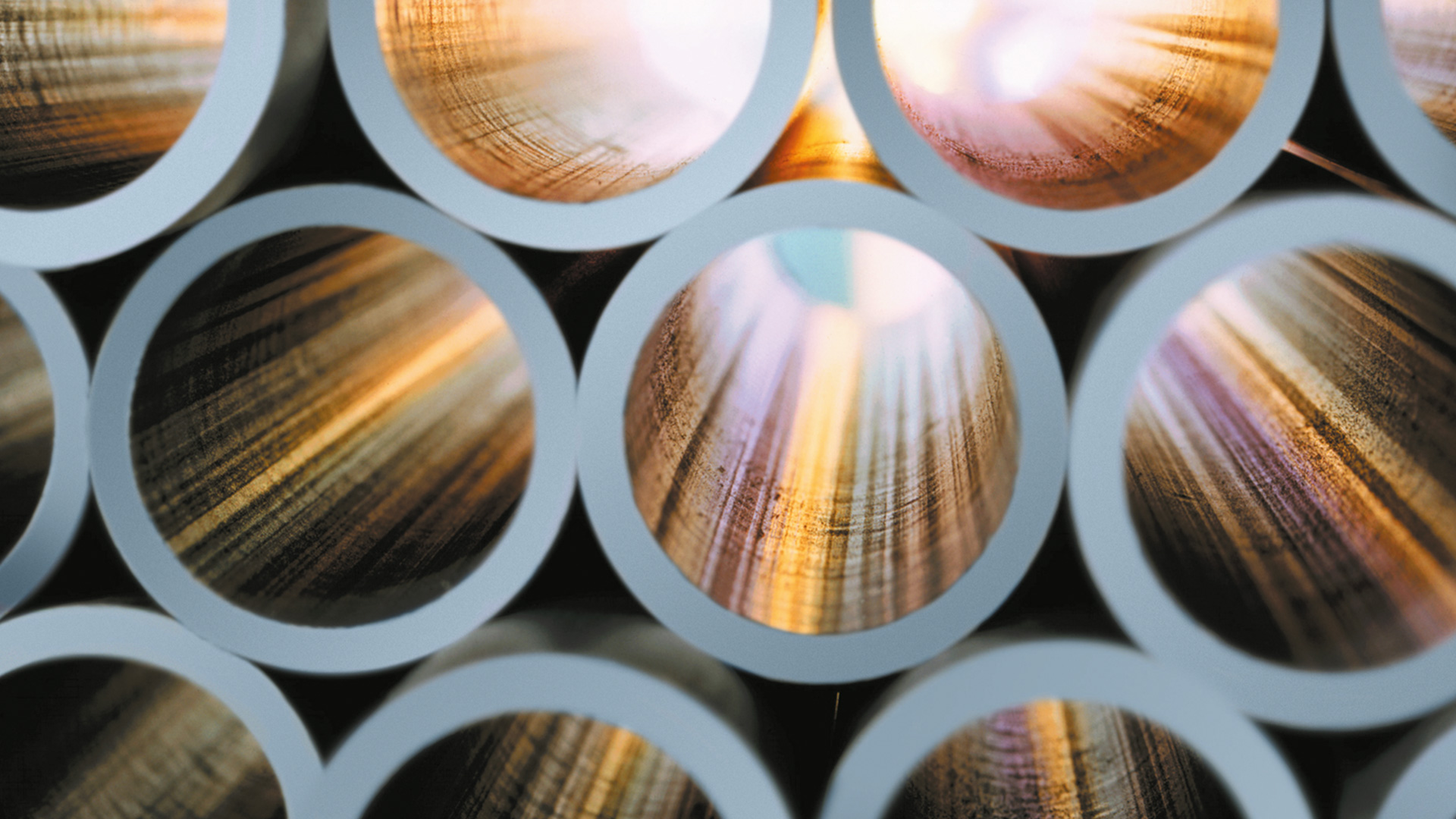

Foundries and metal casting

During smelting, quality analysis is essential as you need to make sure metals and alloys adhere to applicable norms and standards as well as customer specifications. Once your products are finished, their quality needs to be evaluated. If specifications are not met, microscopy helps reveal the root cause.

Compound microscopes are most commonly used for assessments needed in foundries, either as an upright version, such as the DM6 M, or inverted version, such as the DMi8 A.

Metal recycling

Recycling has become increasingly important in metal production to reduce costs by saving on resources and energy. Microscopes can help you assess used metals to determine quality and decide if they can be used for new metal production.

For a first assessment, a digital microscope or routine stereo is recommended. For more detailed analyses, compound microscopes can serve you best.

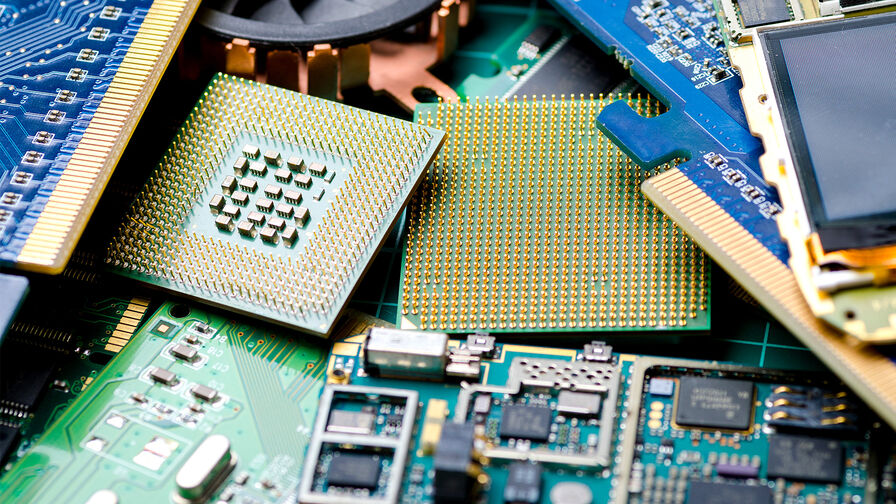

Electronic component recycling

If you are interested in reusing electronic components, it is important to have deeper insights into the materials used. For simultaneous visual and qualitative chemical analysis, a Leica 2-methods-in-one solution combines optical microscopy and laser-induced breakdown spectroscopy (LIBS).

This system can also be used when specific phases or inclusions have been detected in the microstructure and then require further analysis.

Additive manufacturing

For reasons of reducing production time and costs, additive manufacturing processes are considered more and more often, also for metal parts and components. Whether for prototype creation or actual production, microscopes support your QC/QA, failure analysis, as well as your R&D teams in ascertaining that parts produced from additive methods adhere to standards, norms, and customer requirements just as well as those produced with subtractive manufacturing.

Digital or routine stereo microscopes come in handy for a first assessment. Compound microscopes are helpful for more detailed analyses.

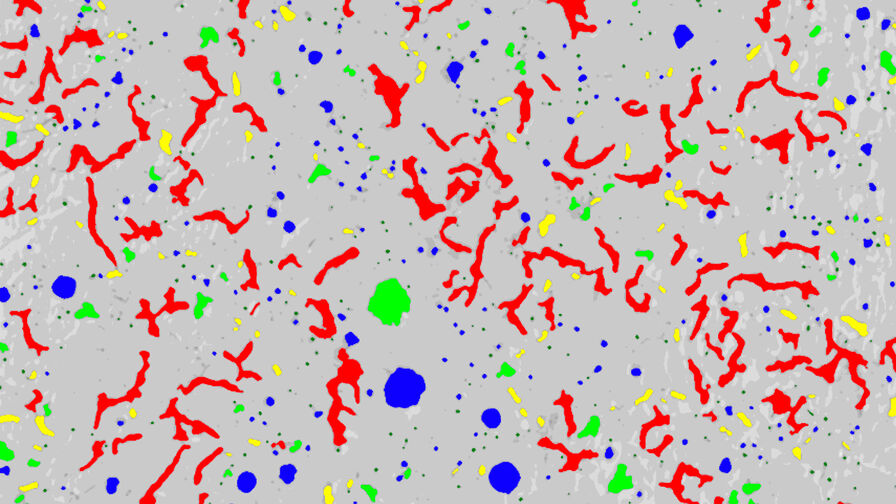

Image acquisition and analysis

Cameras and software are mandatory for image acquisition and analysis with microscopes. For many tasks performed in the metal industries, quantitative analysis is needed. This requirement is made more efficient with software modules which can automatically recognize phases, measure grain sizes, and count inclusions.

An optimal camera ensures that images reveal the relevant details which should be analyzed with software. A variety of microscope cameras is available, so the imaging task at hand can be perfectly matched with the proper microscope solution.

Frequently asked questions Metal Industry

Depending on the task, correct sample preparation is crucial for revealing and evaluating the microstructure of a metal, especially for quantitative analysis. To be able to see important fine details, e.g., grains, phases, etc., the performance of a microscope solution needs to be taken into consideration.

A metallographic microscope is optimized for imaging the microstructure of metals and alloys. Samples can be analyzed quantitatively by using a variety of different illuminations and contrast methods. For more information, please refer to the articles: Metallography with Color and Contrast & Metallography – an Introduction

For routine sample observation, the DM2700 M upright materials microscope is a great choice. It provides LED illumination and multiple contrast methods which can optimally reveal the microstructure.

If the sample throughput must be high, then opting for the DM4 M or DM6 M upright materials microscope will help you work efficiently. It will also give you peace of mind, as all settings can be saved and recalled at the push of a button.

Inverted microscopes, such as the DMi8 A / C / M, give users more flexibility and can be easier to use than upright microscopes. Read about the benefits of inverted microscopes for metallography in this Science Lab article: Five Advantages of Inverted Over Upright Microscopes in Industrial Applications