Science Lab

Science Lab

Das Wissensportal von Leica Microsystems bietet Ihnen Wissens- und Lehrmaterial zu den Themen der Mikroskopie. Die Inhalte sind so konzipiert, dass sie Einsteiger, erfahrene Praktiker und Wissenschaftler gleichermaßen bei ihrem alltäglichen Vorgehen und Experimenten unterstützen. Entdecken Sie interaktive Tutorials und Anwendungsberichte, erfahren Sie mehr über die Grundlagen der Mikroskopie und High-End-Technologien - werden Sie Teil der Science Lab Community und teilen Sie Ihr Wissen!

Filter articles

Tags

Berichtstyp

Produkte

Loading...

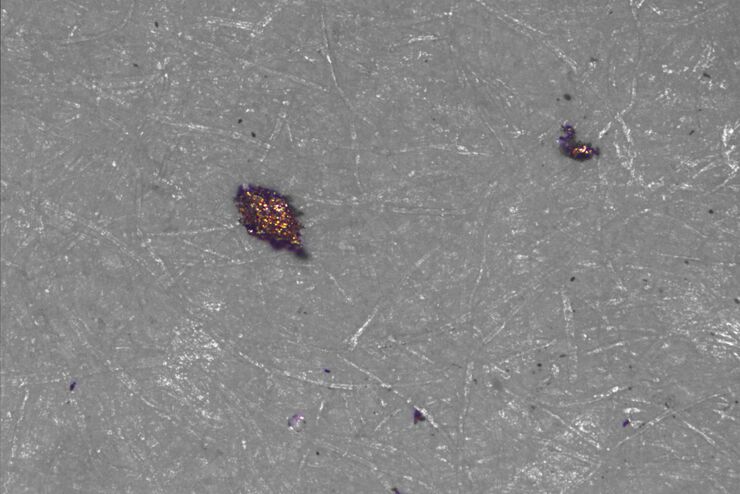

Erkennung von Batteriepartikeln während des Produktionsprozesses

In diesem Artikel wird erläutert, wie die Partikelerkennung und -analyse von Batterien mit optischer Mikroskopie und Laserspektroskopie für eine schnelle, zuverlässige und kostengünstige…

Loading...

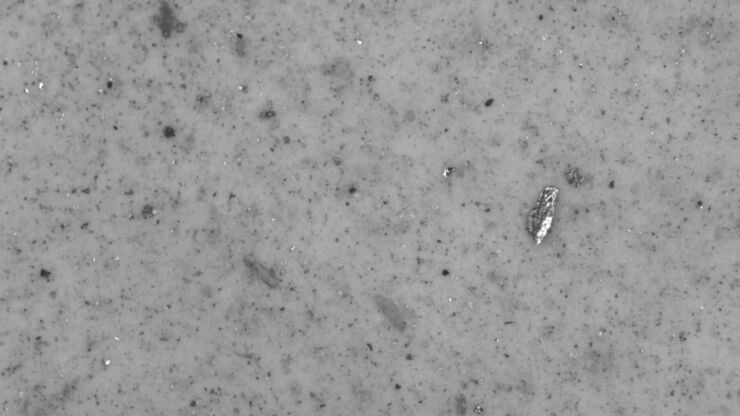

Key Factors for Efficient Cleanliness Analysis

An overview of the key factors necessary for technical cleanliness and efficient cleanliness analysis concerning automotive and electronics manufacturing and production is provided in this article.

Loading...

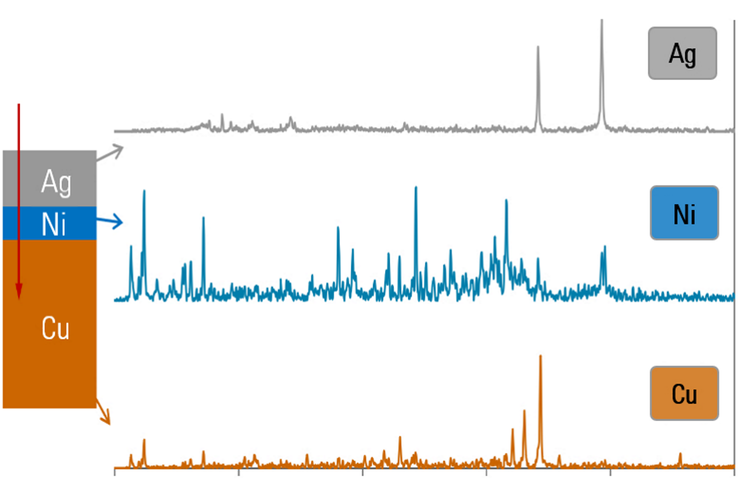

Structural and Chemical Analysis of IC-Chip Cross Sections

This article shows how electronic IC-chip cross sections can be efficiently and reliably prepared and then analyzed, both visually and chemically at the microscale, with the EM TXP and DM6 M LIBS…

Loading...

3 Factors Determine the Damage Potential of Particles

This article discusses the 3 factors for determining the potential of a particle to cause damage to parts and components in the automotive and electronic industry. These factors include the…

Loading...

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

Loading...

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Loading...

Technische Sauberkeit von Automobilkomponenten und -teilen

In diesem Artikel werden die ISO-Norm 16232 und die VDA 19-Richtlinien erläutert und die Verfahren zur Partikelanalyse kurz zusammengefasst. Diese liefern wichtige Kriterien für die Sauberkeit von…

Loading...

Keeping Particulate Contamination Under Control in Pharmaceutical Products

This article describes how a 2-methods-in-1 solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) can be utilized for identification of particulate contaminants in the…

Loading...

Depth Profiling and Layer Analysis for Inspection of Materials with a 2-In-1 Solution Combining Optical Microscopy and Laser Spectroscopy

In addition to simultaneous visual and chemical inspection, a 2-methods-in-1 materials analysis solution, which combines optical microscopy and laser induced breakdown spectroscopy (LIBS), can also be…