Leica DM4 M & DM6 M

Microscopios verticales

Microscopios ópticos

Productos

Inicio

Leica Microsystems

Leica DM4 M & DM6 M Microscopios verticales de materiales

Sin olvidar ni un solo ajuste

Lea nuestros últimos artículos

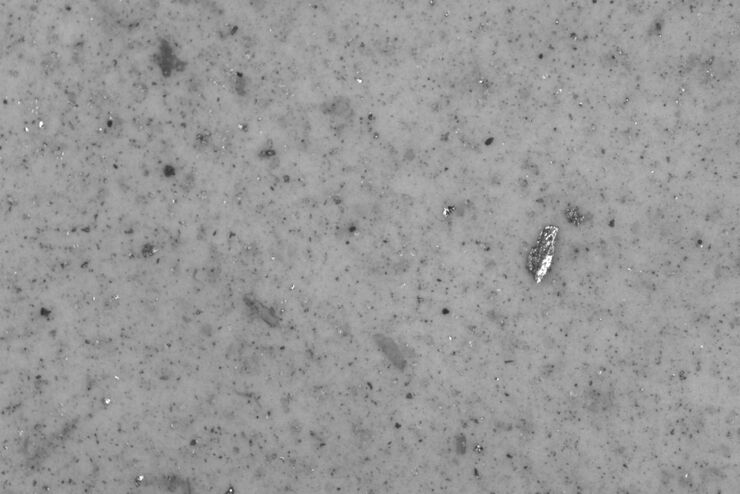

Visualizing Photoresist Residue and Organic Contamination on Wafers

As the scale of integrated circuits (ICs) on semiconductors passes below 10 nm, efficient detection of organic contamination, like photoresist residue, and defects during wafer inspection is becoming…

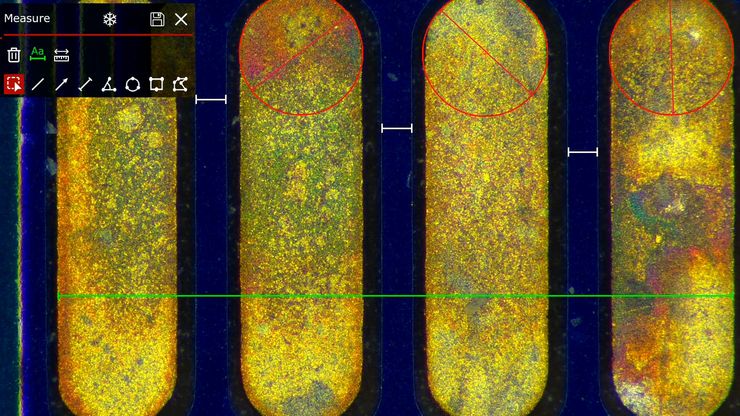

6-Inch Wafer Inspection Microscope for Reliably Observing Small Height Differences

A 6-inch wafer inspection microscope with automated and reproducible DIC (differential interference contrast) imaging, no matter the skill level of users, is described in this article. Manufacturing…

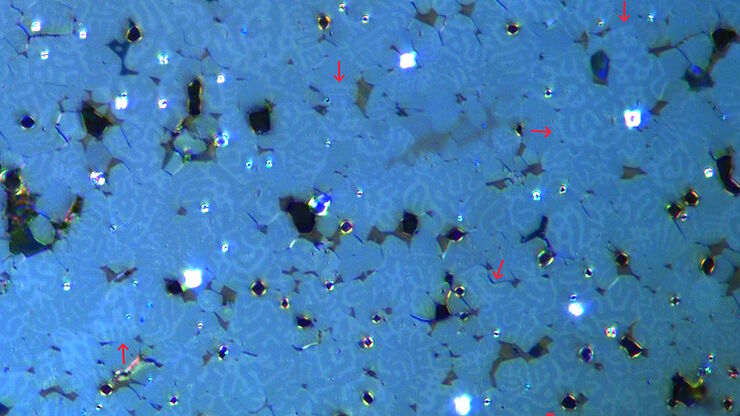

Rapidly Visualizing Magnetic Domains in Steel with Kerr Microscopy

The rotation of polarized light after interaction with magnetic domains in a material, known as the Kerr effect, enables the investigation of magnetized samples with Kerr microscopy. It allows rapid…

How to Select the Right Measurement Microscope

With a measurement microscope, users can measure the size and dimensions of sample features in both 2D and 3D, something crucial for inspection, QC, failure analysis, and R&D. However, choosing the…

Microscope Calibration for Measurements: Why and How You Should Do It

Microscope calibration ensures accurate and consistent measurements for inspection, quality control (QC), failure analysis, and research and development (R&D). Calibration steps are described in this…

Key Factors for Efficient Cleanliness Analysis

An overview of the key factors necessary for technical cleanliness and efficient cleanliness analysis concerning automotive and electronics manufacturing and production is provided in this article.

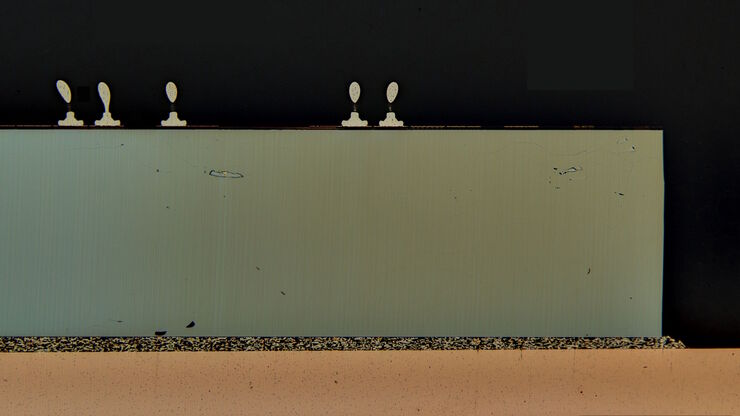

Structural and Chemical Analysis of IC-Chip Cross Sections

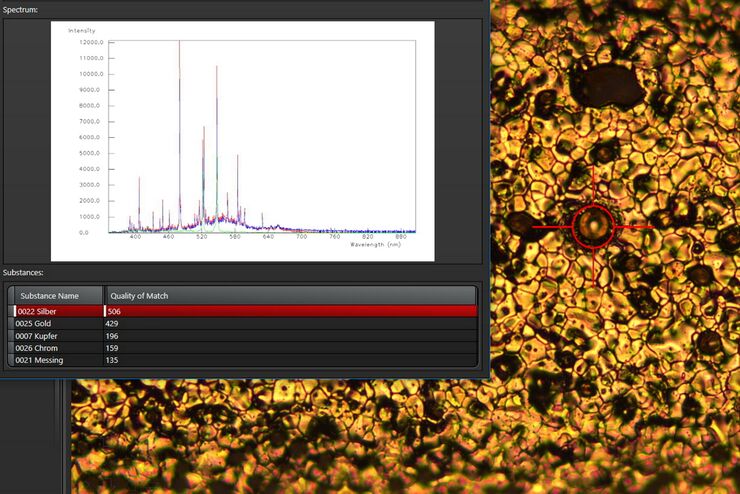

This article shows how electronic IC-chip cross sections can be efficiently and reliably prepared and then analyzed, both visually and chemically at the microscale, with the EM TXP and DM6 M LIBS…

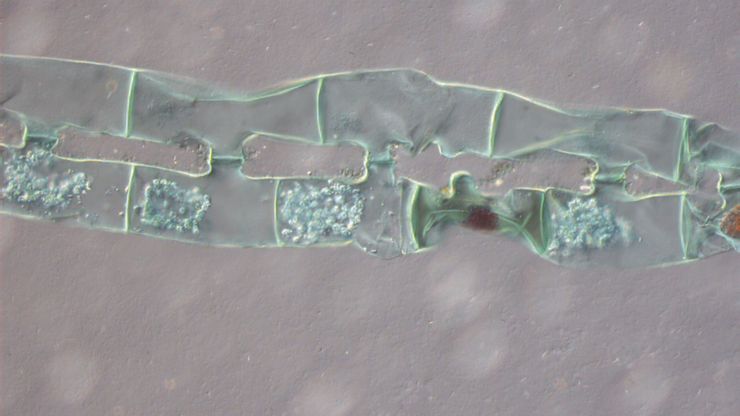

Differential Interference Contrast (DIC) Microscopy

This article demonstrates how differential interference contrast (DIC) can be actually better than brightfield illumination when using microscopy to image unstained biological specimens.

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

Efficient Particle Counting and Analysis

This report discusses particle counting and analysis using optical microscopy for cleanliness of parts and components. Particle counting and analysis is a critical part of quality assurance in the…

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Cleanliness of Automotive Components and Parts

This article discusses the ISO 16232 standard and VDA 19 guidelines and briefly summarizes the particle analysis methods. They give important criteria for the cleanliness of automotive parts and…

How Industrial Applications Benefit from Fluorescence Microscopy

Watch this free webinar to know more about what you can do with fluorescence microscopy for industrial applications. We will cover a wide range of investigations where fluorescence contrast offers new…

Challenges Faced When Manually Rating Non-Metallic Inclusions (NMIs) to Determine Steel Quality

Rapid, accurate, and reliable rating of non-metallic inclusions (NMIs) is instrumental for the determination of steel quality. This article describes the challenges that arise from manual NMI rating,…

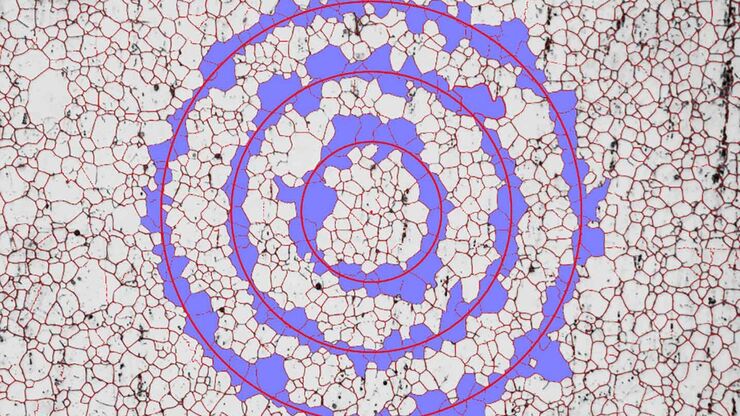

Inverted Microscopes for Grain Size Analysis: Three Factors to Consider

Microscopic steel grain size analysis is useful in determining the quality of steel alloys for a given purpose such as building bridges vs railroad rails. This webinar will describe the preparation of…

Top Issues Related to Standards for Rating Non-Metallic Inclusions in Steel

Supplying components and products made of steel to users worldwide can require that a single batch be compliant with multiple steel quality standards. This user demand creates significant challenges…

Rate the Quality of Your Steel: Free Webinar and Report

This webinar and report describe optimal microscopy solutions for rating steel quality in terms of non-metallic inclusions and reviews the various international and regional standards concerning…

Metallography – an Introduction

This article gives an overview of metallography and metallic alloy characterization. Different microscopy techniques are used to study the alloy microstructure, i.e., microscale structure of grains,…

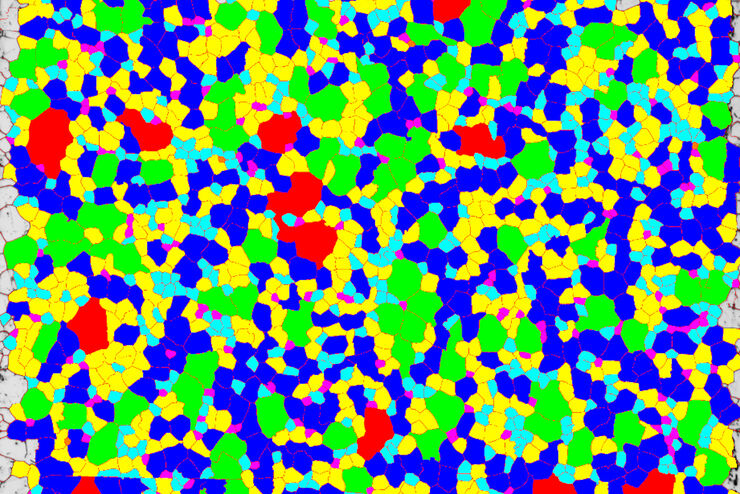

How to Adapt Grain Size Analysis of Metallic Alloys to Your Needs

Metallic alloys, such as steel and aluminum, have an important role in a variety of industries, including automotive and transportation. In this report, the importance of grain size analysis for alloy…

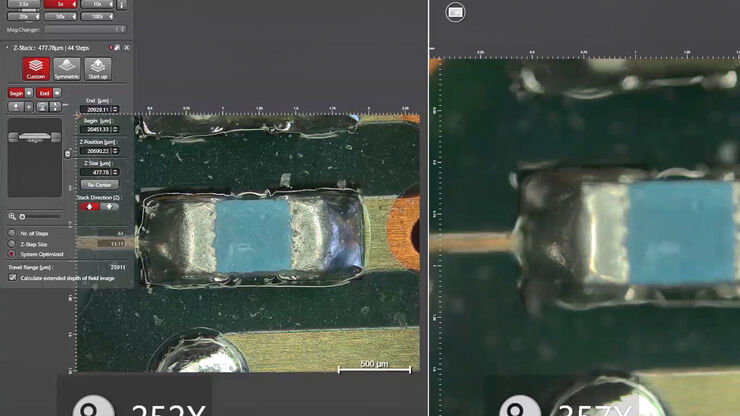

How To Create EDOF (Extended Depth of Focus) Images

Watch this video to see how you can rapidly record sharp optical microscope images of samples with a large height variation. This is done with the optional Extended Depth of Focus (EDOF) function of…

See the Structure with Microscopy - Know the Composition with Laser Spectroscopy

The advantages of a 2-in-1 materials analysis solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) for simultaneous visual and chemical inspection are described in…

Fabricación de baterías

La fabricación de baterías presenta varios retos clave en lo que respecta a la inspección. Se necesitan soluciones para la preparación de muestras y el análisis microscópico visual y químico .

Ciencia y análisis de materiales

Los microscopios desempeñan un papel fundamental para la ciencia y el análisis de materiales. Se utilizan para analizar aleaciones metálicas, cerámicas y polímeros con fines de investigación y control…

Fields of Application

Microscopios para la industria del automóvil y el transporte

Nuestras soluciones inteligentes para la captura y procesamiento de imágenes le ayudan a dirigir aplicaciones especiales con las que satisfacer sus necesidades, tanto presentes como futuras, lo que le…

Clasificación de la calidad del acero

La eficiencia mejorada para la clasificación de inclusiones no metálicas permite a los proveedores de acero y a los fabricantes industriales verificar la calidad del acero en menos tiempo a fin de…

Microscopios forenses

Como científico forense, sus microscopios y su equipo de adquisición de imágenes deben aportar exactitud, calidad, precisión y reproducibilidad de los resultadospara examinar las pruebas con plenas…

Metalografía

El análisis microestructural de metales, aleaciones y otros materiales puede optimizarse aprovechando un microscopio metalográfico de Leica.

Limpieza técnica

For industrial and electronics manufacturers as well as non-regulated pharma applications, solutions for an efficient technical cleanliness offer significant advantages.

Mercados de microscopía industrial

Maximizar el tiempo de actividad y alcanzar los objetivos de forma eficiente ayudan a su cuenta de resultados. Las soluciones de microscopía de Leica le permiten conocer hasta el más mínimo detalle de…

Industria metalúrgica

Los microscopios de Leica para la industria metalúrgica son útiles para evaluar la calidad de los materiales y garantizar el cumplimiento con la normativa aplicable.

Fabricación de baterías

La fabricación de baterías presenta varios retos clave en lo que respecta a la inspección. Se necesitan soluciones para la preparación de muestras y el análisis microscópico visual y químico .

Microscopios de medición

Los microscopios de medición son útiles para determinar las dimensiones de características de la muestra durante controles de calidad, análisis de fallos e investigación y desarrollo. Averigüe más…