UC Enuity

전자현미경 시료 전처리

제품소개

홈

Leica Microsystems

UC Enuity 울트라마이크로톰

최첨단 자동화 및 정밀도 경험

최신 기사를 읽어 보세요

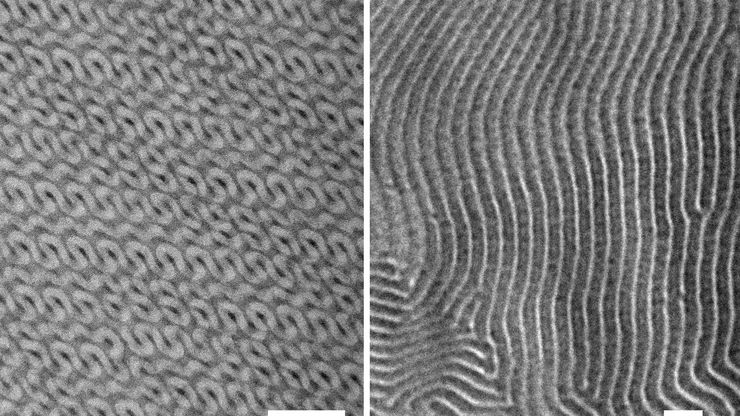

Ultramicrotome Sectioning of Polymers for TEM Analysis

We demonstrate the capabilities of the UC Enuity ultramicrotome from Leica Microsystems for preparing ultrathin sections of polymer samples under both ambient and cryogenic conditions. By presenting…

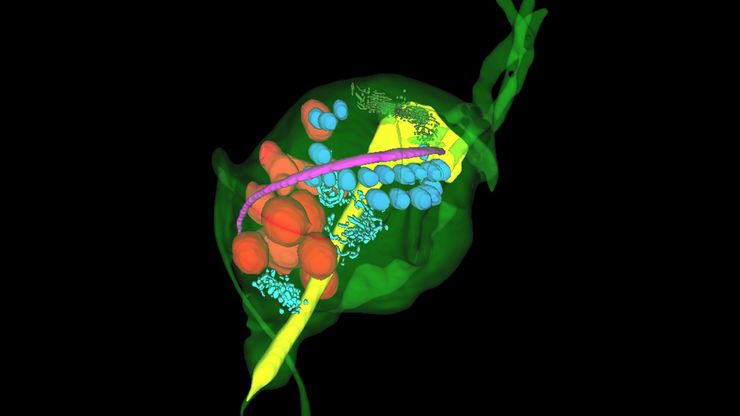

Volume EM and AI Image Analysis

The article outlines a detailed workflow for studying biological tissues in three dimensions using volume-scanning electron microscopy (volume-SEM) combined with AI-assisted image analysis. The focus…

Integrated Serial Sectioning and Cryo-EM Workflows for 3D Biological Imaging

This on-demand webinar explores how integrated tools can support electron microscopy workflows from sample preparation to image analysis. Experts Andreia Pinto, Adrian Boey, and Hoyin Lai present the…

신경과학 연구

신경변경 질환에 대해 더 잘 이해하기 위해 노력하고 있거나 신경계 기능을 연구하고 계십니까? 라이카마이크로시스템즈의 이미지 솔루션을 통해 발전을 이룰 수 있는 방법을 알아보세요.

Mastering Polymer Sectioning with Helmut Gnaegi

When it comes to ultramicrotomy, few names carry the weight of Helmut Gnaegi. As co-founder of Diatome, a global leader in diamond knife technology, Helmut has spent decades refining the art and…

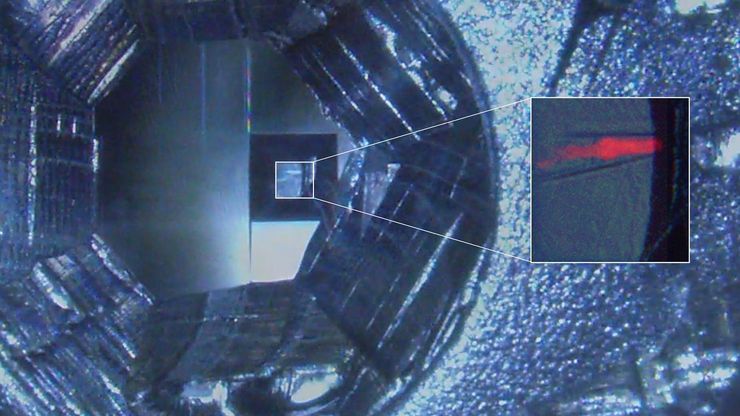

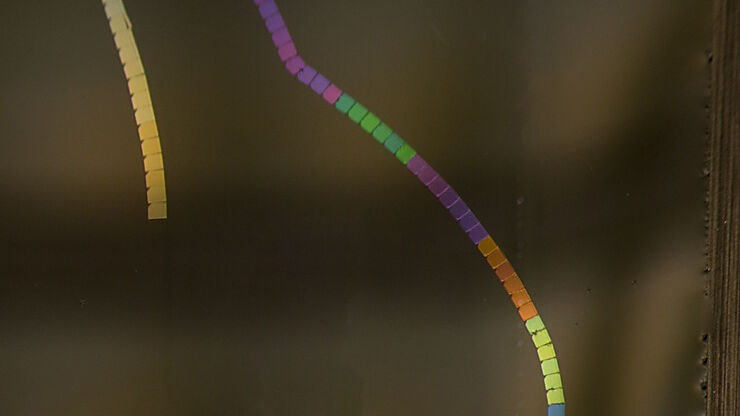

How Fluorescence Guides Sectioning of Resin-embedded EM Samples

Electron microscopes, including transmission electron microscopes (TEM) and scanning electron microscopes (SEM), are widely utilized to gain detailed structural information about biological samples or…

How to Save Time and Samples by Automated Ultramicrotomy

This article describes how 3D micro-CT data of a resin-embedded electron microscopy sample can be used to trim the specimen down to a defined target plane prior to sectioning. The interactive and…

Essential Guide to Ultramicrotomy

When studying samples, to visualize their fine structure with nanometer scale resolution, most often electron microscopy is used. There are 2 types: scanning electron microscopy (SEM) which images the…

How to Automatically Obtain Fluorescent Cells of Interest in a Block-face

Block-face created by automatic trimming under fluorescence.

Mammalian cells of interest, stained with CellTrackerTM Green are visualized within the block-face using the UC Enuity equipped with the…

Improve Your Ultramicrotomy Workflow with Automated Sectioning

Discover advanced digital ultramicrotomy tools for fast and accurate automated sectioning. Learn about autoalignment, and efficient sample trimming leveraging 3D µCT data. See application examples…

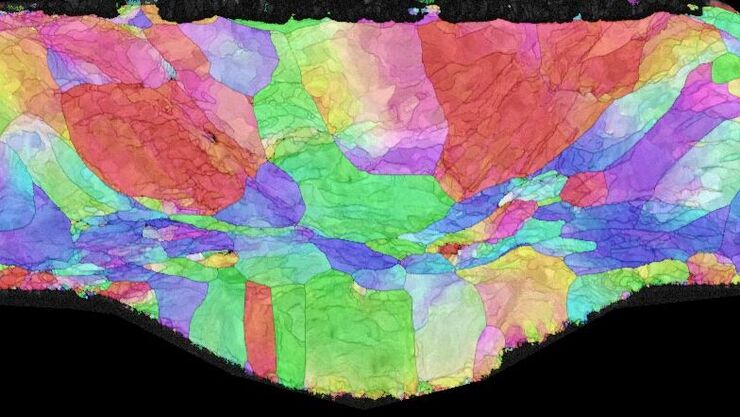

Workflow Solutions for Sample Preparation Methods for Material Science

This brochure presents and explains appropriate workflow solutions for the most frequently required sample preparation methods for material science samples.

Automatic Alignment of Sample and Knife for High Sectioning Quality

Automatic alignment of sample and knife on the ultramicrotome UC Enuity, enabling even untrained users to create ultrathin sections with reduced risk of losing precious sections.

High Quality Sectioning in Ultramicrotomy

Discover the significance of achieving high-quality uniform sections with ultramicrotomy for precise imaging in electron microscopy.

Ultramicrotomy Techniques for Materials Sectioning

Learn about ultramicrotomy for materials sectioning when investigating polymers and brittle materials with transmission (TEM) or scanning electron microscopy (SEM) or atomic force microscopy.

Fields of Application

생명 과학 연구

라이카사의 생명과학사업부는 미세구조의 시각화 및 분석을 위한 혁신 기술 및 기술 전문성을 원하는 scientific community 를 충족시키는 imaging을 지원할 수있습니다. 라이키의 고객을 과학분야의 선두자로 이끌어내는것에 관심이 있습니다.