DM6 M LIBS

Upright Microscopes

Light Microscopes

Products

Home

Leica Microsystems

DM6 M LIBS Material Analysis Microscope

90% time savings: Visual & chemical material inspection 2-in-1

Read our latest articles

Battery Particle Detection During the Production Process

How battery particle detection and analysis is enhanced with optical microscopy and laser spectroscopy for rapid, reliable, and cost-effective QC during battery production is explained in this…

Quality Control via Cross Sections of PCBs, PCBAs, ICs, and Batteries

Why cross sections of printed circuit boards (PCBs) and assemblies (PCBAs), integrated circuits (ICs), and battery components are useful for quality control (QC), failure analysis (FA), and research…

Structural and Chemical Analysis of IC-Chip Cross Sections

This article shows how electronic IC-chip cross sections can be efficiently and reliably prepared and then analyzed, both visually and chemically at the microscale, with the EM TXP and DM6 M LIBS…

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

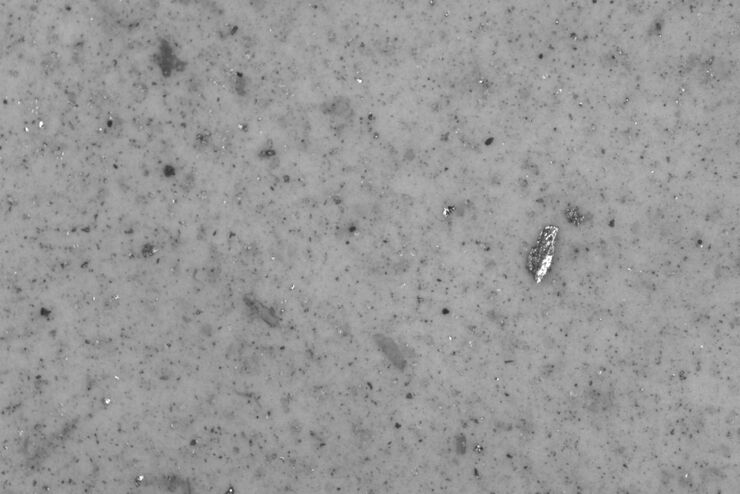

Efficient Particle Counting and Analysis

This report discusses particle counting and analysis using optical microscopy for cleanliness of parts and components. Particle counting and analysis is a critical part of quality assurance in the…

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Cleanliness of Automotive Components and Parts

This article discusses the ISO 16232 standard and VDA 19 guidelines and briefly summarizes the particle analysis methods. They give important criteria for the cleanliness of automotive parts and…

Keeping Particulate Contamination Under Control in Pharmaceutical Products

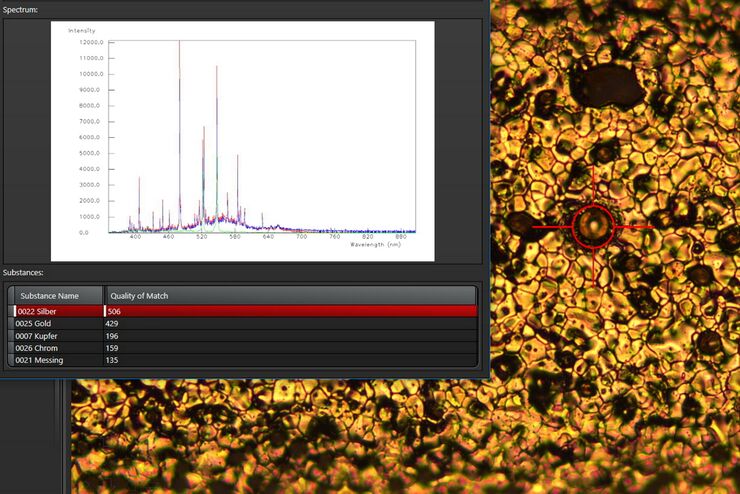

This article describes how a 2-methods-in-1 solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) can be utilized for identification of particulate contaminants in the…

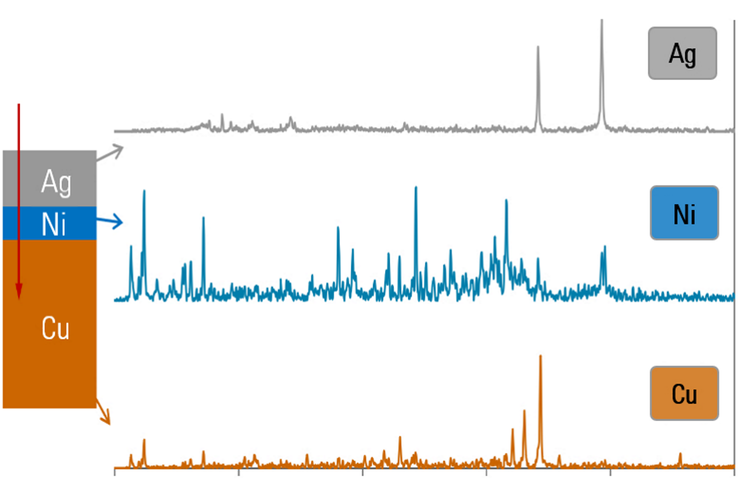

Depth Profiling and Layer Analysis for Inspection of Materials with a 2-In-1 Solution Combining Optical Microscopy and Laser Spectroscopy

In addition to simultaneous visual and chemical inspection, a 2-methods-in-1 materials analysis solution, which combines optical microscopy and laser induced breakdown spectroscopy (LIBS), can also be…

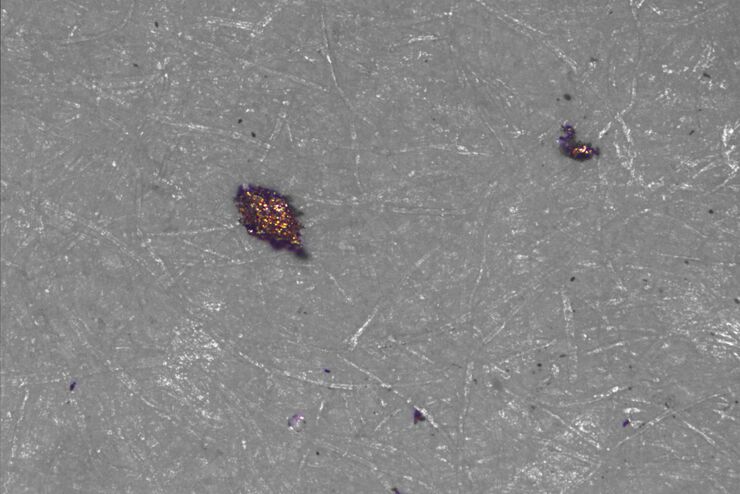

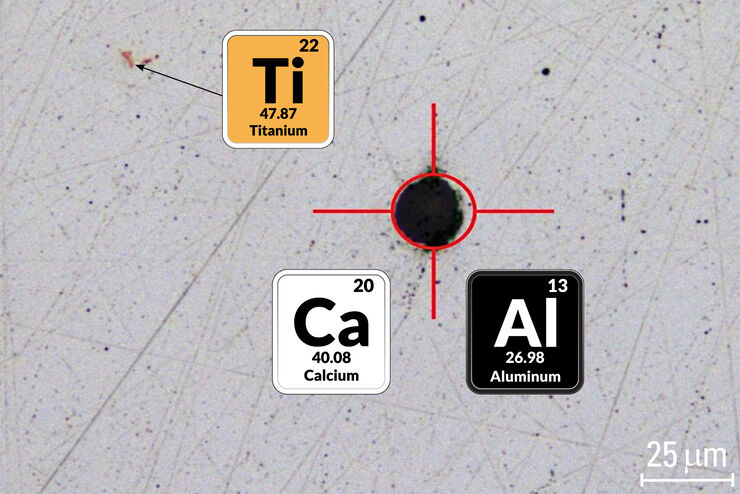

Visual and Chemical Analysis of Steel Microstructure: Faster Rating of Steel Quality

Simultaneous visual and chemical analysis of steel non-metallic inclusions with a 2-methods-in-1 solution, using optical microscopy and laser induced breakdown spectroscopy (LIBS), is described in…

See the Structure with Microscopy - Know the Composition with Laser Spectroscopy

The advantages of a 2-in-1 materials analysis solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) for simultaneous visual and chemical inspection are described in…

Battery Manufacturing Microscopy Solutions

Battery manufacturing has several key challenges concerning inspection. Solutions for sample preparation and microscopic visual and chemical analysis are needed.

Fields of Application

Metallography

The microstructural analysis of metals, alloys, and other materials can be optimized by taking advantage of a Leica metallographic microscope solution.

Automotive & Aerospace Microscopy Solutions

Discover advanced microscopy solutions from Leica Microsystems for quality control, failure analysis, and innovation in automotive, aerospace, railway, and shipbuilding.

Technical Cleanliness Microscopes

For industrial and electronics manufacturers as well as non-regulated pharma applications, solutions for an efficient technical cleanliness offer significant advantages.

Automated Microscopes

Automated microscopes are very useful for applications which require many repetitious observations over a long period of time. Examples are live-cell imaging or high-throughput analysis for quality…

Industrial Microscopy Markets

Maximizing uptime and achieving targets efficiently help your bottom line. Leica microscope solutions can give you insights into the smallest sample details as well as analyze, document, and report…

Metal Industry Microscopy Solutions

Leica microscope solutions for the metal industry are useful for assessing the quality of materials and ensuring compliance with applicable standards.

Cross-Section Analysis for Electronics

Cross-section analysis for electronics enables detailed analysis of failure mechanisms of components like printed circuit boards (PCBs), assemblies (PCBAs), and integrated circuits (ICs).

Electronics & Semiconductor Industry Microscopy Solutions

For electronics and semiconductors, solutions enabling efficient inspection, cross-section and cleanliness analysis, and R&D of PCBs, wafers, IC chips, and batteries are crucial.

Battery Manufacturing Microscopy Solutions

Battery manufacturing has several key challenges concerning inspection. Solutions for sample preparation and microscopic visual and chemical analysis are needed.

Material Science & Analysis

For materials science & analysis, microscopes play a key role. They are used to analyze metal alloys, ceramics, and polymers for research and quality control.