LAS X Materials Science Modules Software for Metallography and Materials Analysis -

Form a powerful microscopy imaging environment

The Leica Application Suite X (LAS X) software has been designed with a focus on usability. It has been developed to guide you through any type of workflow via an explanatory user interface and direct navigation. The underlying capabilities of LAS X can be enhanced with a range of advanced modules and applications to form a powerful microscopy imaging environment. Each LAS X module provides the flexibility to customize a system solution to the users’ individual needs.

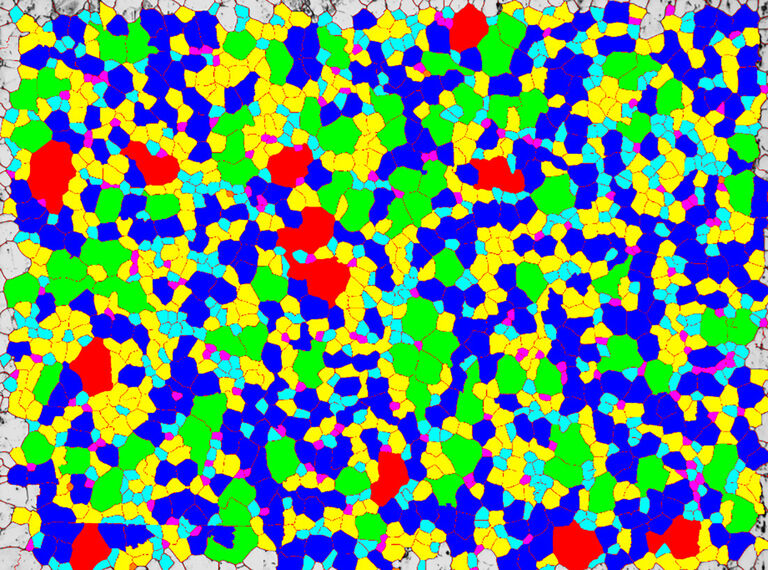

LAS X Grain Expert Software: Superior accuracy and reproducibility in grain analysis

LAS X Grain Expert module provides an environment allowing users to rapidly perform structural analysis of steel and other materials. A multitude of structures and sample types can be studied using highly accurate edge detection algorithms.

This software module also includes traditional stereological methods, such as the Heyn lineal intercept, Jeffries planimetric, and Abrams 3-Circle procedure. These methods are applied automatically, resulting in the direct calculation of grain size. Whereas traditional stereological methods suffer from a 1-dimensional approach to approximate grain size, LAS X Grain Expert applies specific 2-dimensional algorithms to directly measure the grain area. This exceptional approach results in superior accuracy compared to traditional, non-digital methods.

LAS X Grain Expert covers multiple international standards for metallographic grain size analysis, such as ASTM E112, DIN/EN/ISO 643, GOST 5639 and JIS G0551. Derived or related standards, e.g., ASTM E1382 or ASTM E930, which merely describe different technical approaches for grain size analysis are covered within the main standards noted above.

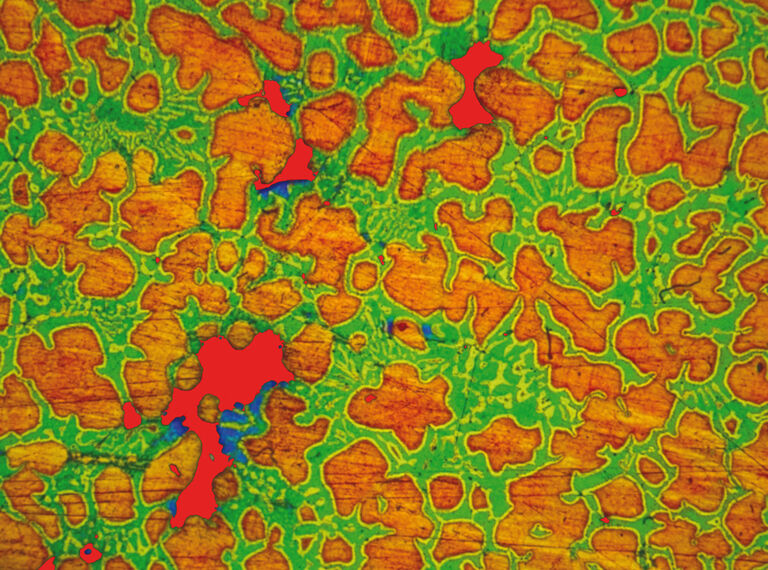

LAS X Phase Expert Software: Improve detection accuracy by up to 250 times

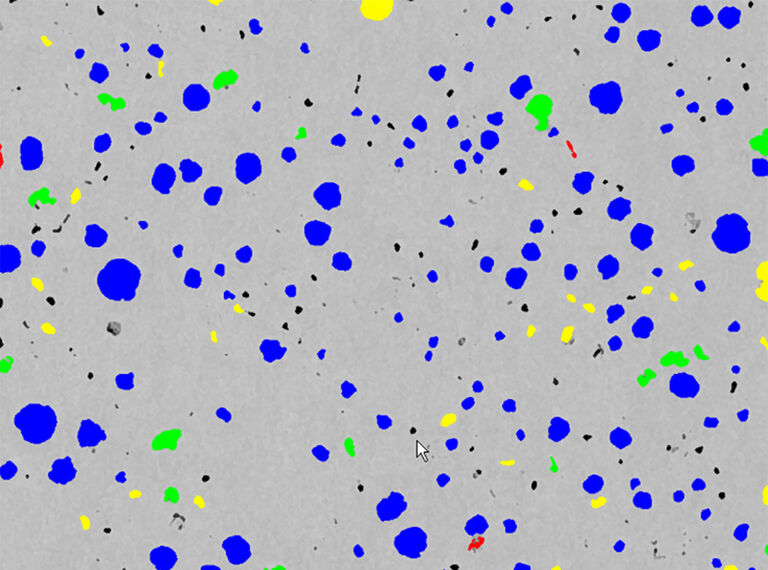

LAS X Phase Expert module enables the advanced analysis of multiple phases and microstructure components. It automatically and precisely measures the area percentage of metals, minerals, and other materials.

Using high bit-depth or HDR images, highly accurate detection algorithms allow for the investigation of phases which show faint differences in the acquired images. Where in traditional images the bit-depth detection resolution is limited to 256 intensity levels, LAS X Phase Expert allows an improvement in detection accuracy of more than 250 times.

Results are typically calculated as the percentage of individual phases in the observed microstructure. Beyond traditional phase analysis, the software also provides additional object measurement capabilities and evaluation of a wide variety of other geometrical and morphological parameters as well.

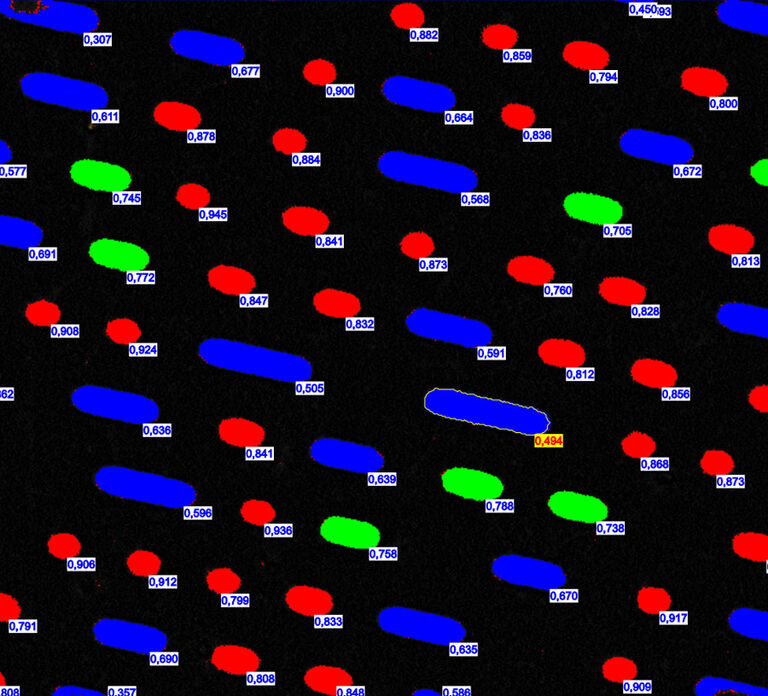

LAS X 2D Analysis Software: Sample classification trainable for your specific needs

The LAS X 2D Analysis module was specifically developed to combine accurate object and area measurements with high flexibility to tailor automated analyses to the user’s particular needs. Various objects and features, such as particles, powders, fibers, voids, porosity, and more, can be analyzed according to geometrical and morphological properties, as well as physical properties, like intensity or color.

The identified objects can be classified based on the parameters available in the LAS X 2D Analysis module. Beyond traditional methods, the software also provides a programmable classifier which allows you to create customized parameters. Simply select a few objects of one or more classes with a click of the mouse and the 2D Analysis module can determine automatically all relevant parameters. Once the specific classifiers are set up, user interaction for future analysis is reduced to a minimum.

The LAS X Multichannel Analysis option allows the detection and classification of objects in parallel and makes available a series of logical operators (AND, OR, XOR, etc.) that allow you to combine individual results to obtain multiple combinations of measurements.

This combined set of powerful analysis features makes the LAS X 2D Analysis/Multichannel Analysis modules the ideal tool for many jobs performed in quality control and advanced research.

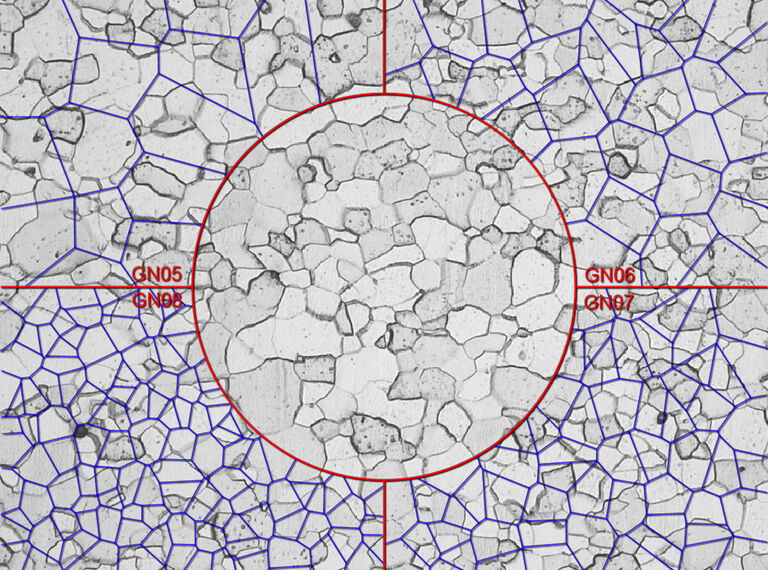

LAS X Reticule Software: Superior ergonomy by digital projection

For measurement and visual comparison based analysis, traditional eyepiece graticules can lead to eyestrain after many hours of use and results with poor accuracy. Digital reticules offer a significant improvement in ergonomics and aid users to maintain consistent accuracy in measurements over time. To document analyses conducted with LAS X Reticule, users can save them as electronic overlays in the respective analyzed image or region of interest.

A digital reticule projects the features of interest directly in the image displayed on the monitor. It can be exchanged with a simple mouse click instead of the need to physically alter optical components. Beyond the fact that it provides a more pleasurable and time-saving work environment, the LAS X Reticule module is also more cost effective than traditional solutions. There is no need to buy individual graticules or combinations of eyepieces and graticules. This application provides more than 50 digital reticule files, including specific solutions for Phase Analysis, Grain Size Analysis and Non-Metallic Inclusion Rating according to various international standards. The digital reticule files can be edited and additional files can be designed using open source drawing software.

LAS X Cast Iron Expert Software: Structural analysis of nodular/ductile or compacted cast iron

LAS X Cast Iron Expert module provides an environment for the quick analysis of graphite microstructures in cast iron, such as ductile/nodular or compacted.

Unlike traditional comparison based approaches, LAS X Cast Iron Expert determines type, shape, size and distribution of graphite nodules automatically. Analyses performed with the module conform to procedures described in various international standards. Results obtained can also be expressed according to these same international standards (ASTM A247, ISO 945-2, JIS G 5502).

Besides the analysis of graphite nodules on etched samples, the software also assists in determining the ferrite/pearlite ratio. Utilizing high bit depth or HDR images and advanced contrast methods, the unique detection algorithms of the LAS X Cast Iron Expert module allow for the rapid analysis of graphite, ferrite and pearlite in parallel. This software can also be used to assess a wide variety of other geometrical and morphological parameters.

LAS X Metallography Toolbox: Flexible-to-use tools for stereology-based structural analysis

The add-on, LAS X Metallography Toolbox, enhances the capabilities of the LAS X 2D Measurement module making it a versatile toolbox for stereological analysis of metallographic/metallurgical samples. In addition, it can be turned into a dedicated tool for a wide variety of applications in metallography and materials science.

It simplifies the manual tasks involved when defining parameters for calibrated measurements, such as baseline lengths, lineal intercepts, point counting, segments of circles, or multi-layer coating thickness.

Both assigning individual classes to measurements and comparative analysis of the related parameters are made possible. Thus, component and phase specific results can be generated.

LAS X Decarburization Expert Module: Structural analysis of surface carbon depletion in heat treated steel

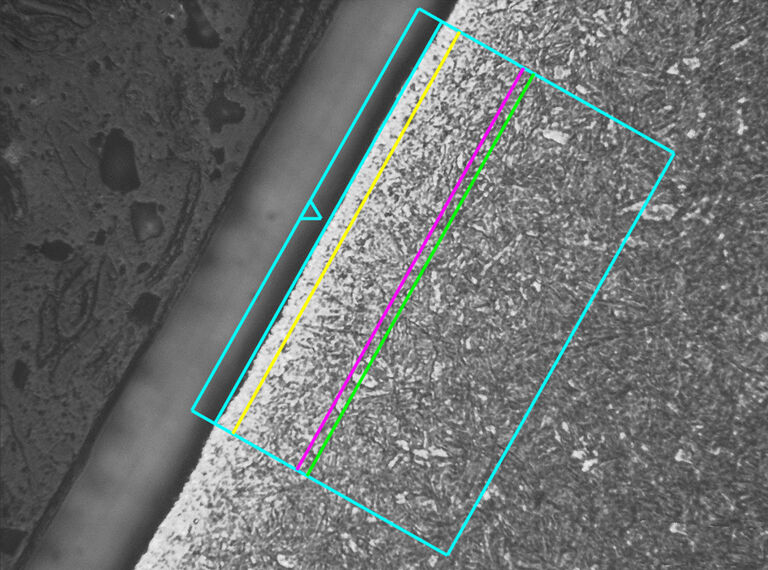

LAS X Decarburization Expert module is a dedicated environment for the analysis of carbon depletion due to tempering in air or thermal hardening of steel. Carbon depletion - or decarburization - affects the properties and hence the quality of the tempered steel. LAS X Decarburization Expert analyses for the functional decarburization depth, the depth at which the original material properties are unaffected.

A selection of advanced image pre-processing filters can additionally aid the user to overcome artifacts originating from sample preparation and etching.

Advanced analysis algorithms automatically correlate the parameters provided for the material and product specifications and calculate the final result. The software works completely automatically but the operator constantly has the ability to interact with it.

LAS X Decarburization Expert software covers multiple international standards used for determining the decarburization depth of steel (ASTM 1077, DIN 50192, ISO/DIN/EN 3887, JIS G0558, etc.).