LAS X Cleanliness Expert

Microscope Software

Products

Home

Leica Microsystems

LAS X Cleanliness Expert Software

Target contamination fast

Read our latest articles

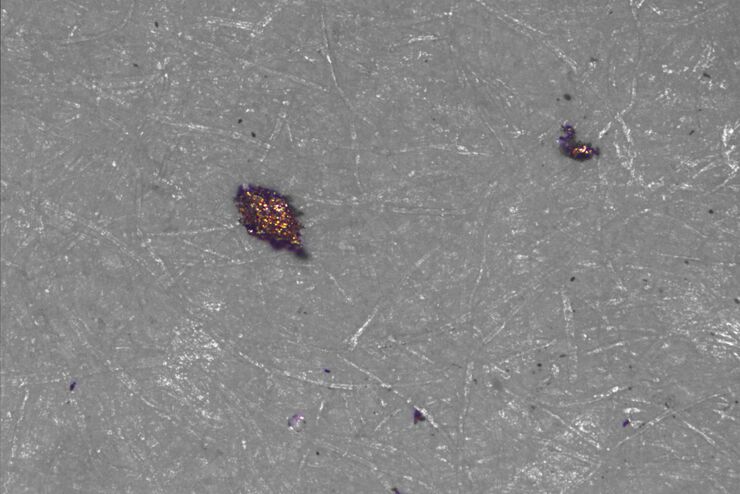

Battery Particle Detection During the Production Process

How battery particle detection and analysis is enhanced with optical microscopy and laser spectroscopy for rapid, reliable, and cost-effective QC during battery production is explained in this…

Key Factors for Efficient Cleanliness Analysis

An overview of the key factors necessary for technical cleanliness and efficient cleanliness analysis concerning automotive and electronics manufacturing and production is provided in this article.

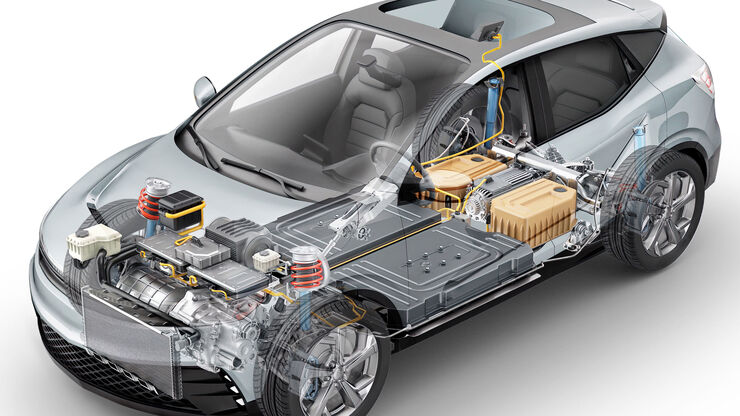

Technical Cleanliness in the Automotive Industry for Electromobility

This free on-demand webinar covers the increasing focus on technical cleanliness in the automotive industry for electromobility and the VDA 19.1 revision.

3 Factors Determine the Damage Potential of Particles

This article discusses the 3 factors for determining the potential of a particle to cause damage to parts and components in the automotive and electronic industry. These factors include the…

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

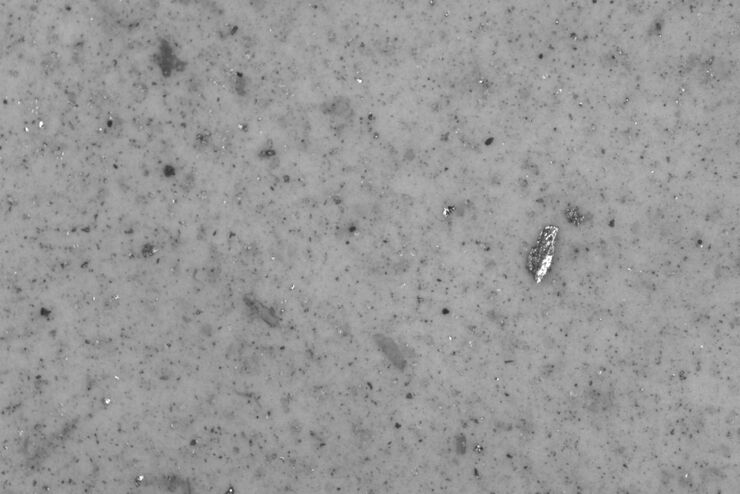

Cleanliness Analysis for Particulate Contamination

Devices, products, and their components fabricated in many industries can be quite sensitive to contamination and, as a result, have stringent requirements for technical cleanliness. Measurement…

Efficient Particle Counting and Analysis

This report discusses particle counting and analysis using optical microscopy for cleanliness of parts and components. Particle counting and analysis is a critical part of quality assurance in the…

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Cleanliness of Automotive Components and Parts

This article discusses the ISO 16232 standard and VDA 19 guidelines and briefly summarizes the particle analysis methods. They give important criteria for the cleanliness of automotive parts and…

Fields of Application

Automotive & Aerospace

Discover advanced microscopy solutions from Leica Microsystems for quality control, failure analysis, and innovation in automotive, aerospace, railway, and shipbuilding.

Technical Cleanliness

For industrial and electronics manufacturers as well as non-regulated pharma applications, solutions for an efficient technical cleanliness offer significant advantages.

Material Analysis Microscopes

Materials analysis requires microscope solutions for the imaging, measurement, and analysis of features across a variety of materials like metal alloys, semiconductors, glass and ceramics, as well as…

Industrial Microscopy Markets

Maximizing uptime and achieving targets efficiently help your bottom line. Leica microscope solutions can give you insights into the smallest sample details as well as analyze, document, and report…