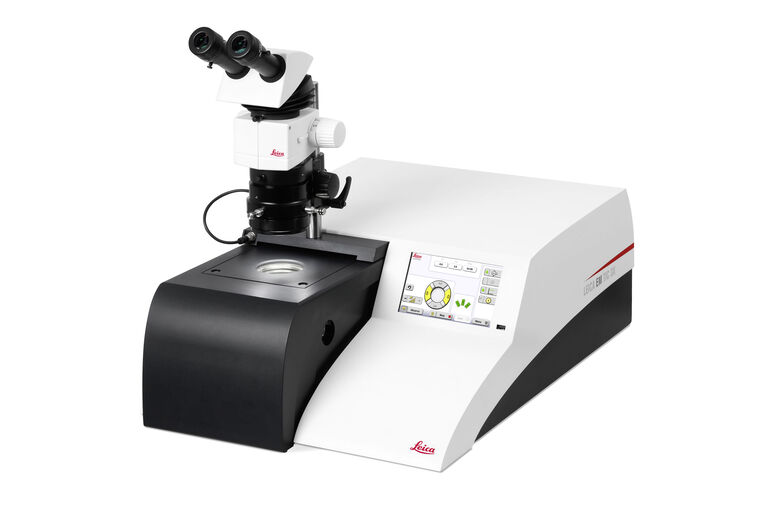

EM TIC 3X Ion Beam Milling System

Efficiency and flexibility

The updated version of the EM TIC 3X is based on our motto ‘with the user for the user’ in combining performance and flexibility in a practically-relevant way.

The doubled ion milling rate of the latest EM TIC 3X can be further enhanced with the option of five different stages adapted to your application requirements.

Reproducible results by Ion Milling

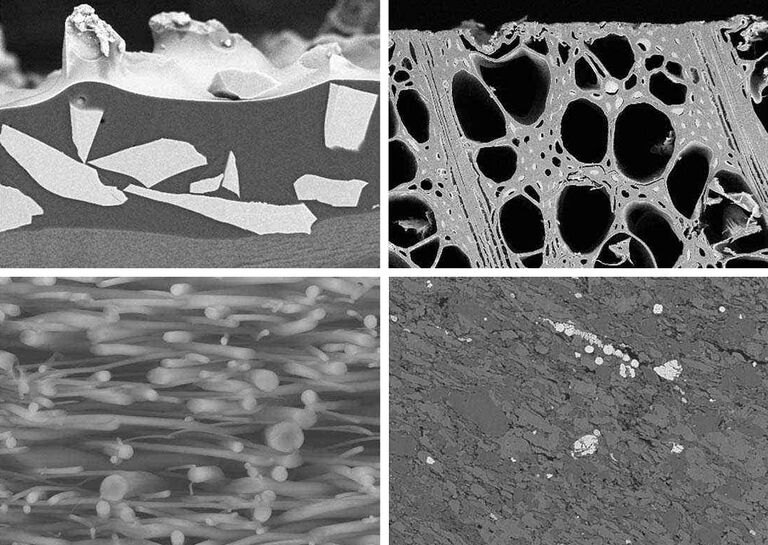

The Triple Ion Beam Milling System, EM TIC 3X allows production of cross sections and planar surfaces for Scanning Electron Microscopy (SEM), Microstructure Analysis (EDS, WDS, Auger, EBSD) and, AFM investigations.

With the EM TIC 3X you achieve high quality surfaces of almost any material at room temperature or cryo, revealing the internal structures of the sample in a near native state as possible.

As convenient as never before!

Efficiency

What really counts regarding the efficiency of an ion beam miller is excellent quality results with high throughput. It’s not enough that we could increase the milling rate by a factor of 2 compared to the previous version but the unique triple ion beam system optimizes the preparation quality and reduces working time.

Up to three samples can be processed in one session. Cross sectioning and polishing can be performed by one stage.

Workflow solutions provide safe and efficient transfer of samples to subsequent preparation instruments or analysis systems.

Flexible system – Adaptable to your needs at any time

The flexible choice of stages makes the EM TIC 3X a perfect instrument not only for high through-put but also for contract laboratories. Depending on your needs the EM TIC 3X can be configured individually using interchangeable stages:

- Standard stage

- Multiple sample stage

- Rotary stage

- Cooling stage or

- Vacuum Cryo Transfer Docking Station

for applications of standard preparation, high throughput processing, as well as the preparation of extremely heat sensitive samples such as polymers, rubbers or biological materials at low temperatures.

Environmentally controlled Workflow Solution

The VCT docking port in combination with the EM TIC 3X offers the perfect workflow for surfacing environmentally sensitive and/or cryogenic samples which can be

- biological,

- geological or

- industrial material.

They can be subsequently transferred to our coating systems EM ACE600 or EM ACE900 and/or SEM systems under inert gas/vacuum/cryo conditions.

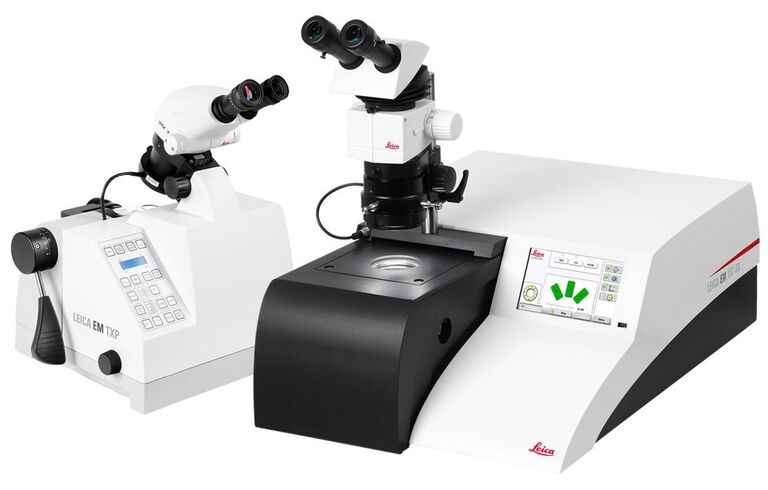

Standard Workflow Solution - Create synergies with the EM TXP

Prior to use of the EM TIC 3X, mechanical preparation is often required to get as close as possible to the area of interest. The EM TXP is a unique target surfacing system developed for cutting and polishing samples prior to follow-on techniques with instruments such as the EM TIC 3X.

The EM TXP is specially designed to pre-prepare samples by sawing, milling, grinding, and polishing. It excels with challenging specimens where pinpointing and preparing difficult targets becomes easy.