Microscopic Defects in Electroplating

How to identify root causes of defects during electroplating of components with optical microscopy and LIBS

About the webinar

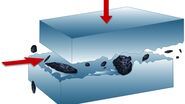

During electroplating, contamination, residues, or inclusions can quickly lead to a noticeable reduction in product quality or even failure of full batches. Similar types of contamination or defects can be found in production environments of the electronics and automotive industries.

In this webinar, it will be presented how Laser Induced Breakdown Spectroscopy (LIBS) is used in quality control to identify quickly the root cause of defects (contamination) during electroplating of products. Using typical examples from the field, it will be shown how these samples can be investigated with a 2-in1-solution combining optical microscopy and LIBS for visual and chemical analysis of materials.

What to expect in the webinar

Key learnings

- Find out more about typical surface defects which occur during electroplating of electronics

- Learn how typical defects or contamination can be quickly and efficiently analyzed using a 2-in1-solution for visual and chemical analysis

- Understand how to use LIBS (laser induced breakdown spectroscopy) to identify the root cause of contamination or defects