Science Lab

Science Lab

The knowledge portal of Leica Microsystems offers scientific research and teaching material on the subjects of microscopy. The content is designed to support beginners, experienced practitioners and scientists alike in their everyday work and experiments. Explore interactive tutorials and application notes, discover the basics of microscopy as well as high-end technologies – become part of the Science Lab community and share your expertise!

Filter articles

Tags

Story Type

Products

Loading...

3 Factors Determine the Damage Potential of Particles

This article discusses the 3 factors for determining the potential of a particle to cause damage to parts and components in the automotive and electronic industry. These factors include the…

Loading...

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

Loading...

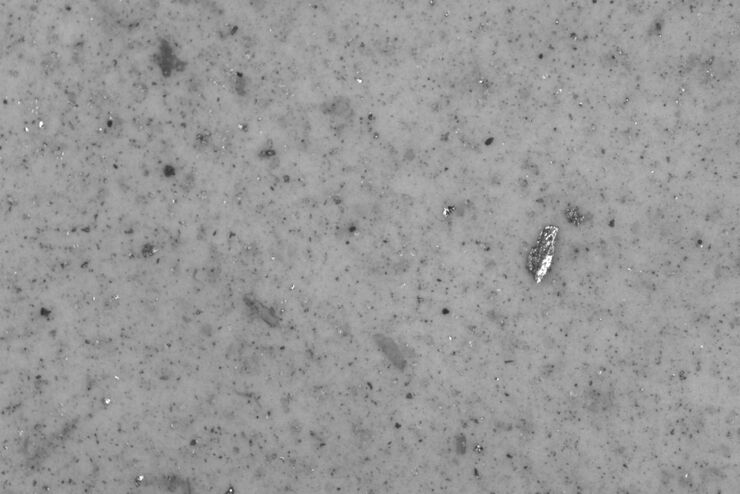

Cleanliness Analysis for Particulate Contamination

Devices, products, and their components fabricated in many industries can be quite sensitive to contamination and, as a result, have stringent requirements for technical cleanliness. Measurement…

Loading...

Efficient Particle Counting and Analysis

This report discusses particle counting and analysis using optical microscopy for cleanliness of parts and components. Particle counting and analysis is a critical part of quality assurance in the…

Loading...

Cleanliness of Automotive Components and Parts

This article discusses the ISO 16232 standard and VDA 19 guidelines and briefly summarizes the particle analysis methods. They give important criteria for the cleanliness of automotive parts and…

Loading...

Keeping Particulate Contamination Under Control in Pharmaceutical Products

This article describes how a 2-methods-in-1 solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) can be utilized for identification of particulate contaminants in the…

Loading...

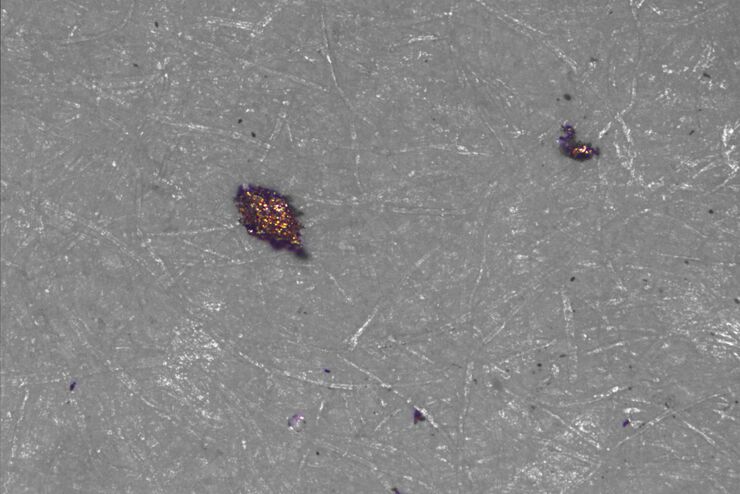

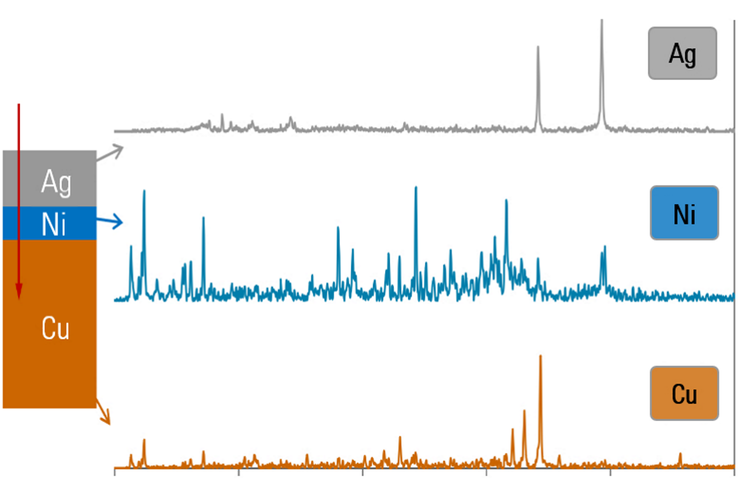

Depth Profiling and Layer Analysis for Inspection of Materials with a 2-In-1 Solution Combining Optical Microscopy and Laser Spectroscopy

In addition to simultaneous visual and chemical inspection, a 2-methods-in-1 materials analysis solution, which combines optical microscopy and laser induced breakdown spectroscopy (LIBS), can also be…

Loading...

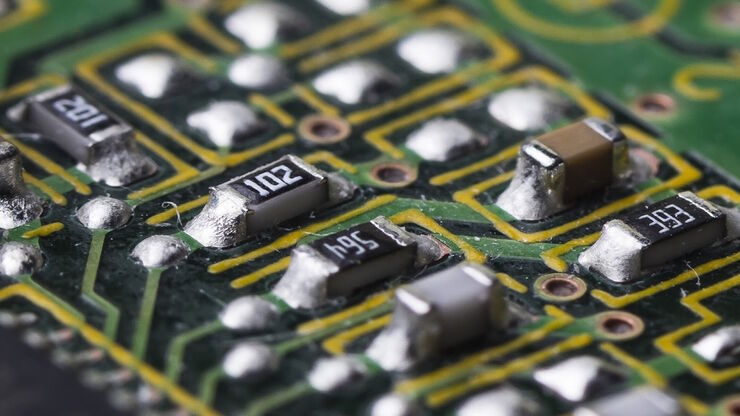

Performing Elemental Analysis down to the Micro Scale

If you work in electronic component analysis, you will be familiar with the many challenges posed. Whether you are identifying metallic particles or checking product authenticity, it’s important to…

Loading...

Introduction to Ion Beam Etching with the EM TIC 3X

In this article you can learn how to optimize the preparation quality of your samples by using the ion beam etching method with the EM TIC 3X ion beam milling machine. A short introduction of the…