Kay Scheffler , Dr.

Produkt Manager, Leica Microsystems CMS GmbH, Wetzlar

6-Inch Wafer Inspection Microscope for Reliably Observing Small Height Differences

A 6-inch wafer inspection microscope with automated and reproducible DIC (differential interference contrast) imaging, no matter the skill level of users, is described in this article. Manufacturing…

Visualizing Photoresist Residue and Organic Contamination on Wafers

As the scale of integrated circuits (ICs) on semiconductors passes below 10 nm, efficient detection of organic contamination, like photoresist residue, and defects during wafer inspection is becoming…

Key Factors for Efficient Cleanliness Analysis

An overview of the key factors necessary for technical cleanliness and efficient cleanliness analysis concerning automotive and electronics manufacturing and production is provided in this article.

Five Inverted-Microscope Advantages for Industrial Applications

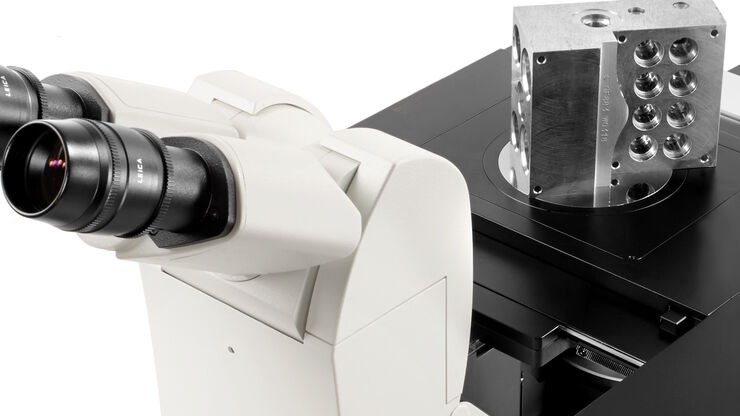

With inverted microscopes, you look at samples from below since their optics are placed under the sample, with upright microscopes you look at samples from above. Traditionally, inverted microscopes…

3 Factors Determine the Damage Potential of Particles

This article discusses the 3 factors for determining the potential of a particle to cause damage to parts and components in the automotive and electronic industry. These factors include the…

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

Effiziente Partikelzählung und -analyse

Dieser Bericht befasst sich mit der Partikelzählung und -analyse unter Verwendung der optischen Mikroskopie bei der technischen Sauberkeitsanalyse von Teilen und Komponenten. Die Partikelzählung und…

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Technische Sauberkeit von Automobilkomponenten und -teilen

In diesem Artikel werden die ISO-Norm 16232 und die VDA 19-Richtlinien erläutert und die Verfahren zur Partikelanalyse kurz zusammengefasst. Diese liefern wichtige Kriterien für die Sauberkeit von…

Keeping Particulate Contamination Under Control in Pharmaceutical Products

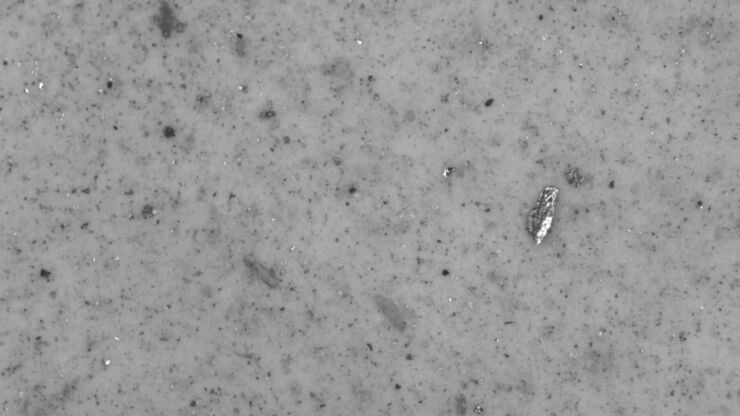

This article describes how a 2-methods-in-1 solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) can be utilized for identification of particulate contaminants in the…

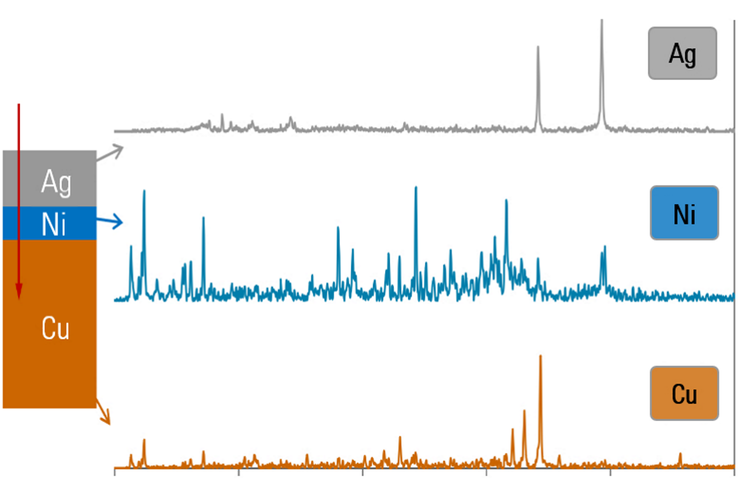

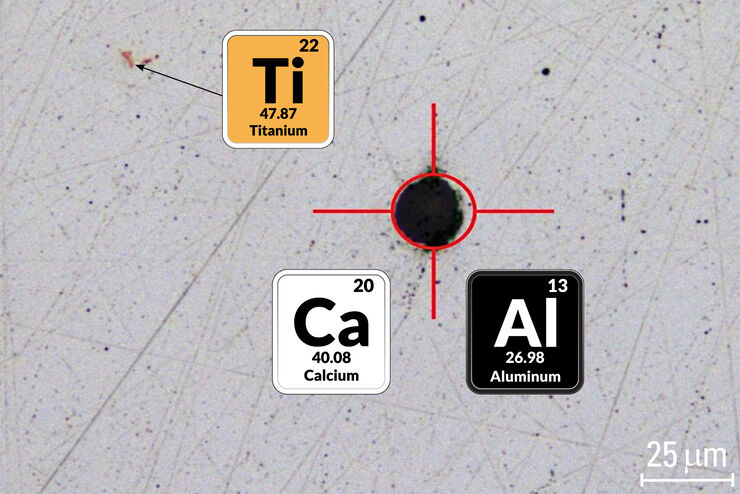

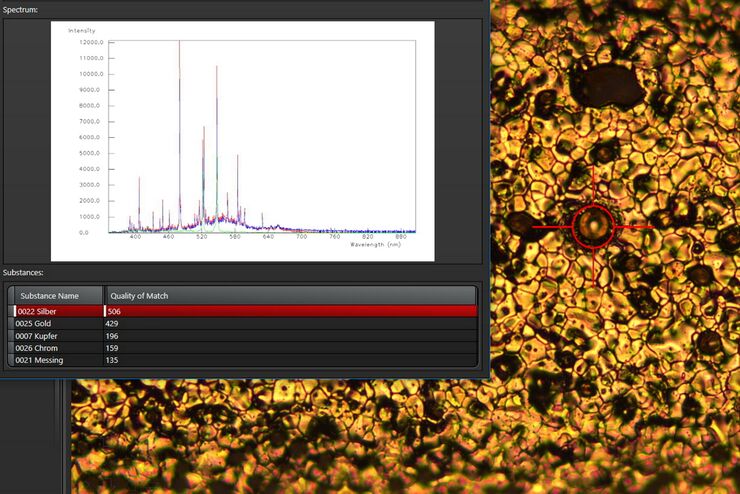

Depth Profiling and Layer Analysis for Inspection of Materials with a 2-In-1 Solution Combining Optical Microscopy and Laser Spectroscopy

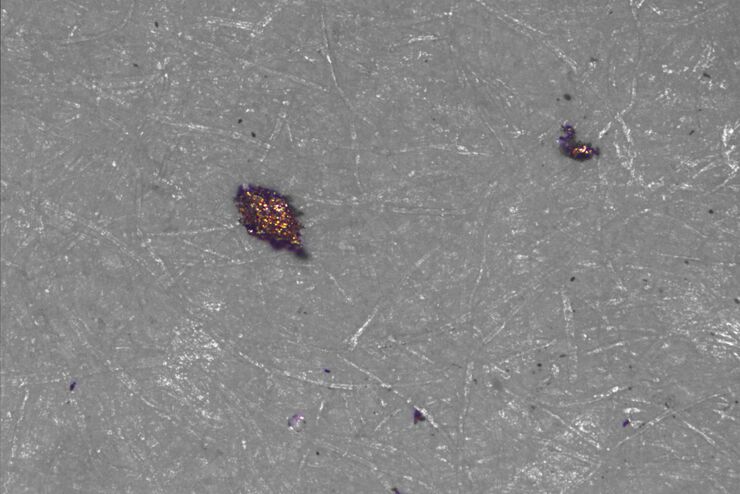

In addition to simultaneous visual and chemical inspection, a 2-methods-in-1 materials analysis solution, which combines optical microscopy and laser induced breakdown spectroscopy (LIBS), can also be…

Visual and Chemical Analysis of Steel Microstructure: Faster Rating of Steel Quality

Simultaneous visual and chemical analysis of steel non-metallic inclusions with a 2-methods-in-1 solution, using optical microscopy and laser induced breakdown spectroscopy (LIBS), is described in…

See the Structure with Microscopy - Know the Composition with Laser Spectroscopy

The advantages of a 2-in-1 materials analysis solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) for simultaneous visual and chemical inspection are described in…