DM6 M LIBS

Microscopios verticales

Microscopios ópticos

Productos

Inicio

Leica Microsystems

DM6 M LIBS Solución de análisis de composición microestructural

Ahorre un 90 % de tiempo: un solo sistema para la inspección química y visual del material

Lea nuestros últimos artículos

Battery Particle Detection During the Production Process

How battery particle detection and analysis is enhanced with optical microscopy and laser spectroscopy for rapid, reliable, and cost-effective QC during battery production is explained in this…

Cross-section Analysis for Electronics Manufacturing

This article describes cross-section analysis for electronics concerning quality control and failure analysis of printed circuit boards (PCBs) and assemblies (PCBAs), integrated circuits (ICs), etc.

Structural and Chemical Analysis of IC-Chip Cross Sections

This article shows how electronic IC-chip cross sections can be efficiently and reliably prepared and then analyzed, both visually and chemically at the microscale, with the EM TXP and DM6 M LIBS…

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

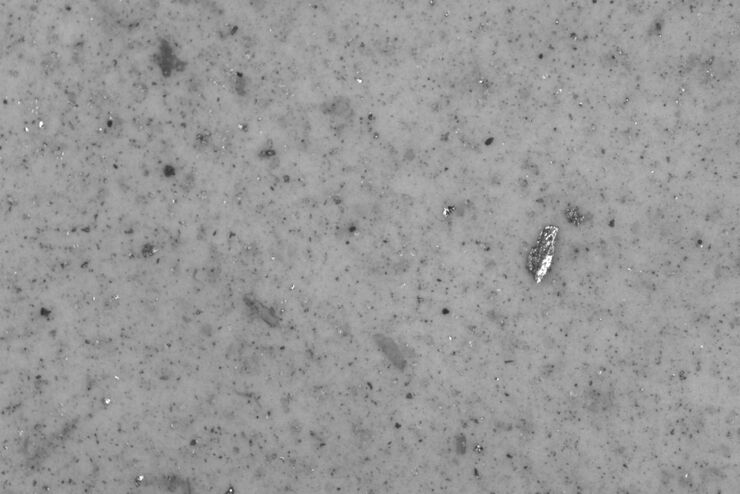

Efficient Particle Counting and Analysis

This report discusses particle counting and analysis using optical microscopy for cleanliness of parts and components. Particle counting and analysis is a critical part of quality assurance in the…

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Cleanliness of Automotive Components and Parts

This article discusses the ISO 16232 standard and VDA 19 guidelines and briefly summarizes the particle analysis methods. They give important criteria for the cleanliness of automotive parts and…

Keeping Particulate Contamination Under Control in Pharmaceutical Products

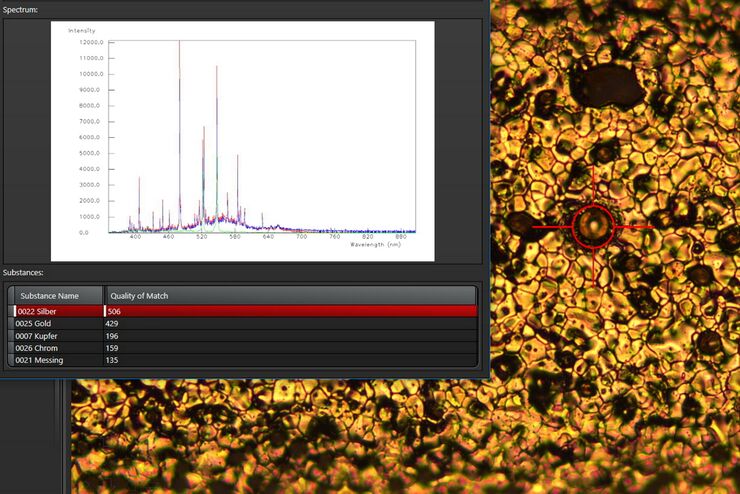

This article describes how a 2-methods-in-1 solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) can be utilized for identification of particulate contaminants in the…

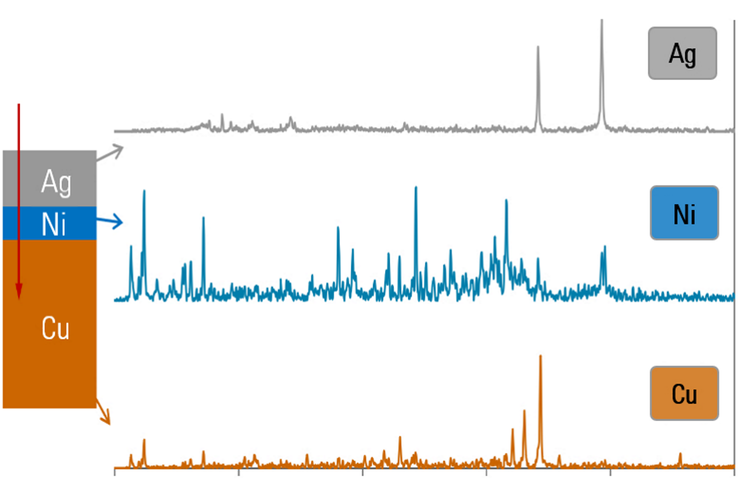

Depth Profiling and Layer Analysis for Inspection of Materials with a 2-In-1 Solution Combining Optical Microscopy and Laser Spectroscopy

In addition to simultaneous visual and chemical inspection, a 2-methods-in-1 materials analysis solution, which combines optical microscopy and laser induced breakdown spectroscopy (LIBS), can also be…

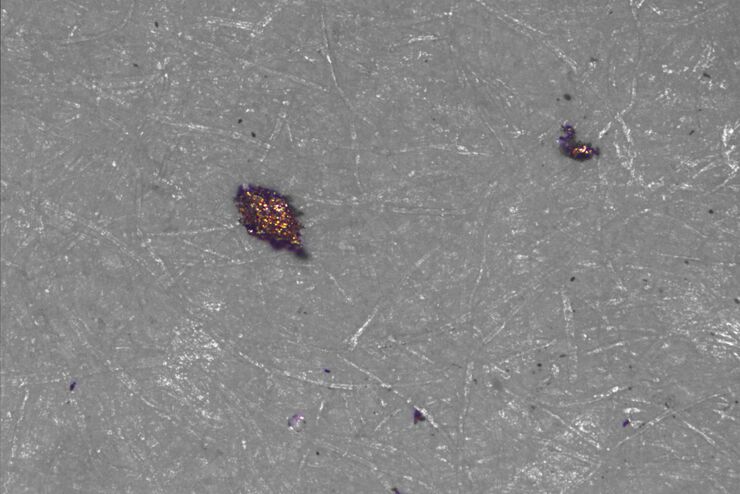

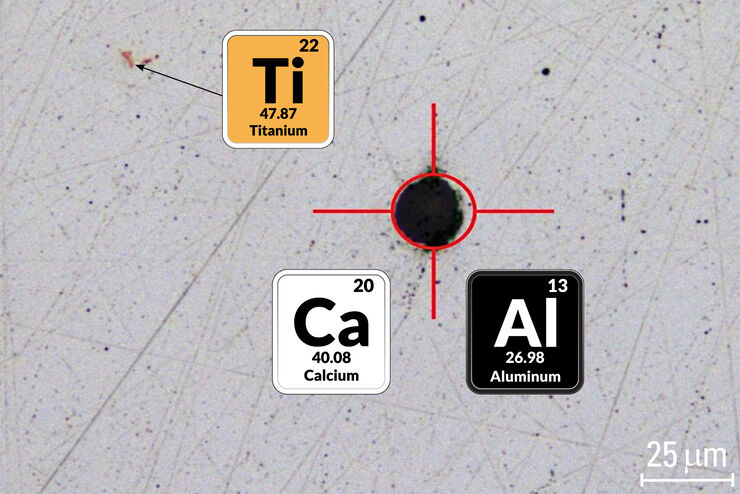

Visual and Chemical Analysis of Steel Microstructure: Faster Rating of Steel Quality

Simultaneous visual and chemical analysis of steel non-metallic inclusions with a 2-methods-in-1 solution, using optical microscopy and laser induced breakdown spectroscopy (LIBS), is described in…

See the Structure with Microscopy - Know the Composition with Laser Spectroscopy

The advantages of a 2-in-1 materials analysis solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) for simultaneous visual and chemical inspection are described in…

Fabricación de baterías

La fabricación de baterías presenta varios retos clave en lo que respecta a la inspección. Se necesitan soluciones para la preparación de muestras y el análisis microscópico visual y químico .

Campos de aplicación

Metalografía

Los microscopios metalográficos de Leica se han optimizado para analizar la microestructura de metales, aleaciones y otros materiales.

Microscopios para la industria del automóvil y el transporte

Nuestras soluciones inteligentes para la captura y procesamiento de imágenes le ayudan a dirigir aplicaciones especiales con las que satisfacer sus necesidades, tanto presentes como futuras, lo que le…

Ciencias de los materiales y geológicas

Necesita las herramientas adecuadas para obtener imágenes y análisis fiables y de alta calidad. Leica Microsystems es la única fuente para todas sus necesidades de investigación. Junto con el apoyo…

Limpieza técnica

For industrial and electronics manufacturers as well as non-regulated pharma applications, solutions for an efficient technical cleanliness offer significant advantages.

Microscopios para análisis de materiales

El análisis de materiales requiere microscopios para la obtención de imágenes, la medición y el análisis de características de diversos materiales, como aleaciones metálicas, semiconductores, vidrio y…

Mercados de microscopía industrial

Maximizar el tiempo de actividad y alcanzar los objetivos de forma eficiente ayudan a su cuenta de resultados. Las soluciones de microscopía de Leica le permiten conocer hasta el más mínimo detalle de…

Industria metalúrgica

Los microscopios de Leica para la industria metalúrgica son útiles para evaluar la calidad de los materiales y garantizar el cumplimiento con la normativa aplicable.

Análisis de cortes transversales para la microelectrónica

El análisis de sección transversal para la electrónica permite un análisis detallado de los mecanismos de fallo de componentes como placas de circuito impreso (PCB), montajes (PCBA) y circuitos…

Industria electrónica y de semiconductores

Para la electrónica y los semiconductores, las soluciones que permiten una inspección eficiente, el análisis de la sección transversal y de la limpieza, y la I+D de PCB, obleas, chips IC y baterías…

Fabricación de baterías

La fabricación de baterías presenta varios retos clave en lo que respecta a la inspección. Se necesitan soluciones para la preparación de muestras y el análisis microscópico visual y químico .

Microscopios de medición

Los microscopios de medición son útiles para determinar las dimensiones de características de la muestra durante controles de calidad, análisis de fallos e investigación y desarrollo. Averigüe más…