DM6 M LIBS

Microscopi verticali

Microscopi ottici

Prodotti

Home

Leica Microsystems

DM6 M LIBS Soluzione per analisi della composizione delle microstrutture

Risparmio di tempo del 90%: ispezione visiva e chimica 2-in-1

Leggi gli articoli più recenti

Battery Particle Detection During the Production Process

How battery particle detection and analysis is enhanced with optical microscopy and laser spectroscopy for rapid, reliable, and cost-effective QC during battery production is explained in this…

Cross-section Analysis for Electronics Manufacturing

This article describes cross-section analysis for electronics concerning quality control and failure analysis of printed circuit boards (PCBs) and assemblies (PCBAs), integrated circuits (ICs), etc.

Structural and Chemical Analysis of IC-Chip Cross Sections

This article shows how electronic IC-chip cross sections can be efficiently and reliably prepared and then analyzed, both visually and chemically at the microscale, with the EM TXP and DM6 M LIBS…

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

Efficient Particle Counting and Analysis

This report discusses particle counting and analysis using optical microscopy for cleanliness of parts and components. Particle counting and analysis is a critical part of quality assurance in the…

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Cleanliness of Automotive Components and Parts

This article discusses the ISO 16232 standard and VDA 19 guidelines and briefly summarizes the particle analysis methods. They give important criteria for the cleanliness of automotive parts and…

Keeping Particulate Contamination Under Control in Pharmaceutical Products

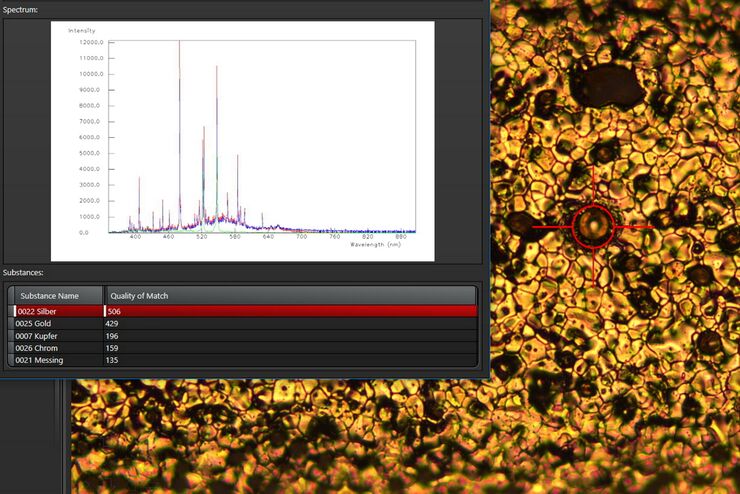

This article describes how a 2-methods-in-1 solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) can be utilized for identification of particulate contaminants in the…

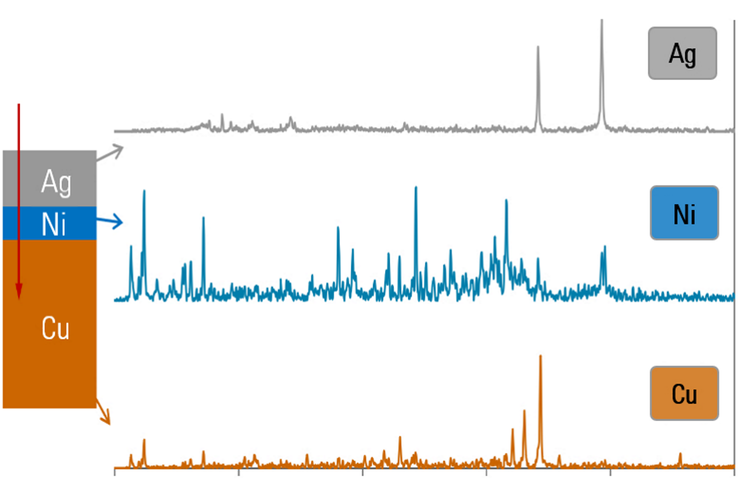

Depth Profiling and Layer Analysis for Inspection of Materials with a 2-In-1 Solution Combining Optical Microscopy and Laser Spectroscopy

In addition to simultaneous visual and chemical inspection, a 2-methods-in-1 materials analysis solution, which combines optical microscopy and laser induced breakdown spectroscopy (LIBS), can also be…

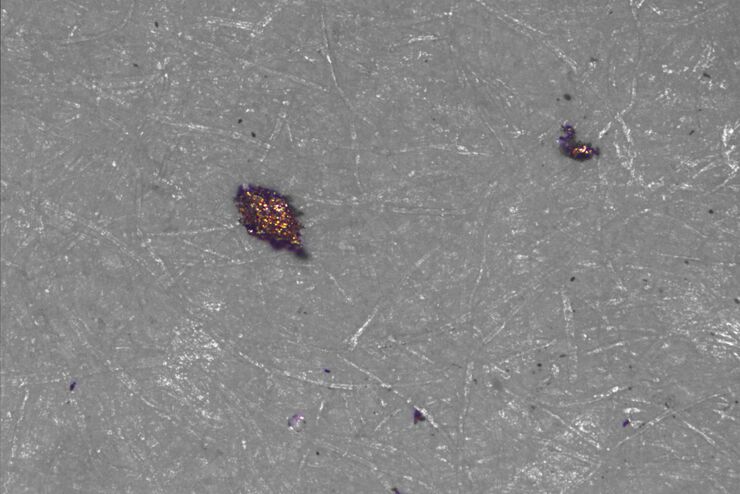

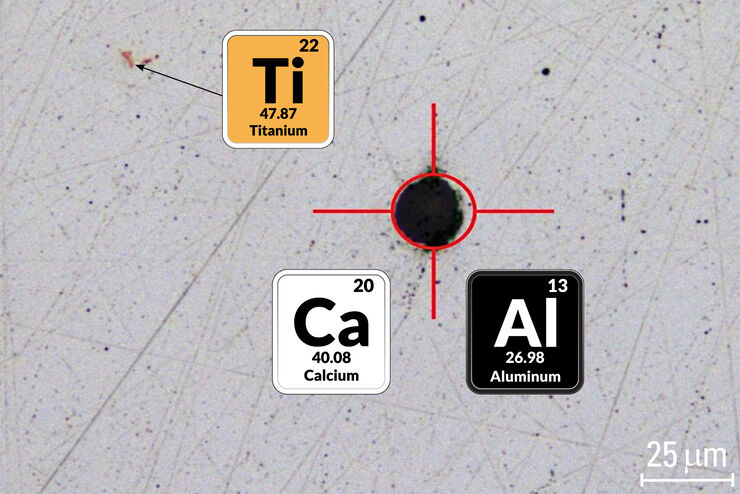

Visual and Chemical Analysis of Steel Microstructure: Faster Rating of Steel Quality

Simultaneous visual and chemical analysis of steel non-metallic inclusions with a 2-methods-in-1 solution, using optical microscopy and laser induced breakdown spectroscopy (LIBS), is described in…

See the Structure with Microscopy - Know the Composition with Laser Spectroscopy

The advantages of a 2-in-1 materials analysis solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) for simultaneous visual and chemical inspection are described in…

Produzione di batterie

La produzione di batterie presenta diverse sfide chiave per quanto riguarda l'ispezione. Sono necessarie soluzioni per la preparazione dei campioni e per l'analisi visiva e chimica…

Campi di applicazione

Metallografia

I microscopi metallografici Leica, sono ottimizzati per l'analisi microstrutturale di metalli, leghe e altri materiali.

Microscopi per le industrie automobilistica e dei trasporti

L’ obiettivo di Leica è essere il vostro affidabile collaboratore che vi guida verso le soluzioni di imaging migliori per le vostre esigenze, per consentirvi di essere sempre un passo avanti alla…

Scienze della terra e dei materiali

Avete bisogno degli strumenti giusti per un' immagine e un' analisi affidabili e di alta qualità. Leica Microsystems è la fonte unica per tutte le vostre esigenze di ricerca. Oltre al supporto locale…

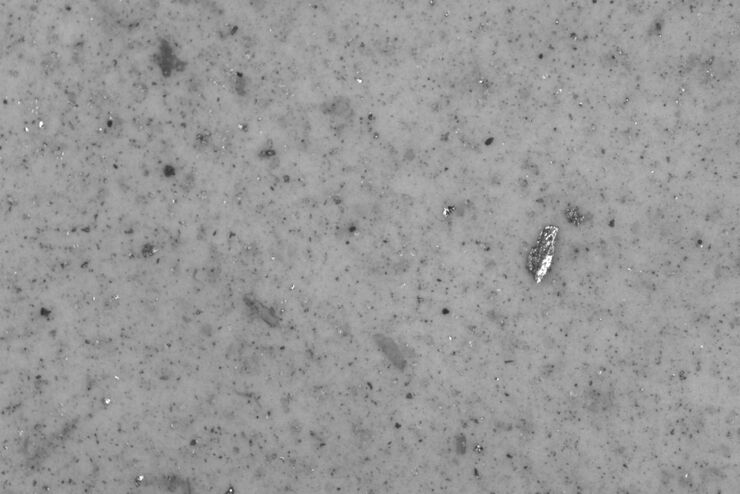

Pulizia tecnica

For industrial and electronics manufacturers as well as non-regulated pharma applications, solutions for an efficient technical cleanliness offer significant advantages.

Microscopi per l'analisi dei materiali

L'analisi dei materiali richiede soluzioni di microscopia per l'imaging, la misurazione e l'analisi delle caratteristiche di una varietà di materiali come leghe metalliche, semiconduttori, vetro e…

Mercati della microscopia industriale

Negli ambienti industriali la tendenza attuale è di migliorare i tempi e raggiungere gli obiettivi in modo veloce per aumentare i profitti. Le soluzioni dedicate alle analisi microscopiche Leica, sono…

Industria metallurgica

Le soluzioni per la microscopia ottica di Leica per l'industria metallurgica sono utilizzate per valutare la qualità dei materiali e garantire la conformità agli standard internazionali.

Analisi in sezione dei componenti elettronici

L'analisi in sezione dei componenti elettronici permette di controllare in modo approfondito i meccanismi che causano i guasti di componenti quali schede a circuito stampato (PCB), gruppi (PCBA) e…

Industria dell'elettronica e dei semiconduttori

Per l'elettronica e i semiconduttori, le soluzioni che consentono un'ispezione veloce sono fondamentali per esempio per l'analisi della sezione trasversale, del grado di pulizia per la ricerca e…

Produzione di batterie

La produzione di batterie presenta diverse sfide chiave per quanto riguarda l'ispezione. Sono necessarie soluzioni per la preparazione dei campioni e per l'analisi visiva e chimica…

Misurazioni al microscopio

I microscopi per misurazioni sono utili per determinare le dimensioni dei campioni durante il controllo qualità, l'analisi dei guasti e la ricerca e sviluppo. Ulteriori informazioni sui microscopi per…