Emspira 3

デジタル顕微鏡

製品紹介

Home

Leica Microsystems

Emspira 3 デジタルマイクロスコープ

検査精度・速度をアップ

最新の記事を読む

Automotive Part Verification and Development according to Specifications

Automotive part verification during the development and production of parts and components by suppliers or manufacturers is important for ensuring that specifications are met. Specifications are…

顕微鏡を知る:被写界深度

顕微鏡において被写界深度は、凹凸の変化が⼤きい構造を持つ試料をピントがあったシャープに観察・撮像するために重要なパラメータです。被写界深度は、開⼝数、解像度、倍率の相関関係によって決定され、解像度とパラメータは反⽐例の関係にあります。被写界深度と解像度のバランスが最適になるように調整することができる顕微鏡もあります。

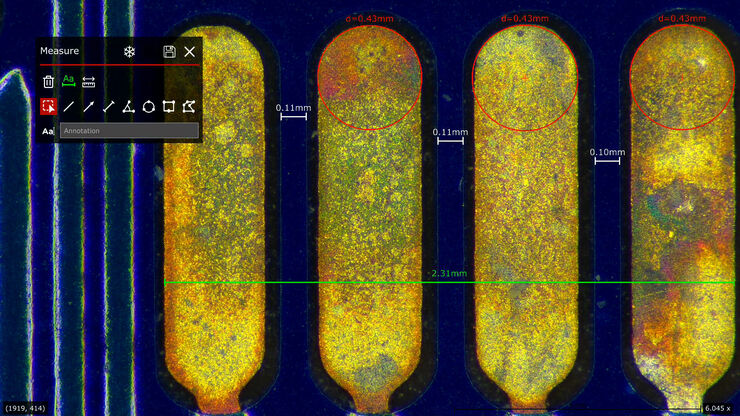

Burr Detection During Battery Manufacturing

See how optical microscopy can be used for burr detection on battery electrodes and determination of damage potential to achieve rapid and reliable quality control during battery manufacturing.

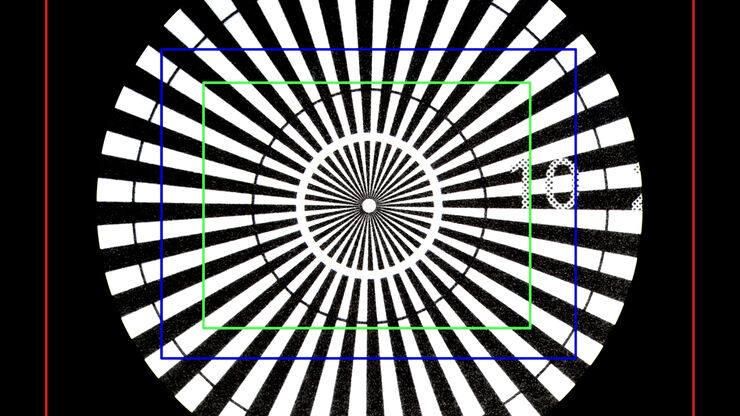

Understanding Clearly the Magnification of Microscopy

To help users better understand the magnification of microscopy and how to determine the useful range of magnification values for digital microscopes, this article provides helpful guidelines.

Digital Inspection Microscope for Industrial Applications

Factors users should consider before choosing a digital inspection microscope for industrial applications, including quality control (QC), failure analysis (FA), and R&D, are described in this…

Alternative Fuels and Why Sustainable Solutions are Important

This free on-demand webinar is about the role of alternative fuel vehicles and why sustainable solutions are of increasing importance to the automotive industry.

Top Challenges for Visual Inspection

This article discusses the challenges encountered when performing visual inspection and rework using a microscope. Using the right type of microscope and optical setup is paramount in order to…

How to Select the Right Solution for Visual Inspection

This article helps users with the decision-making process when selecting a microscope as a solution for routine visual inspection. Important factors that should be considered are described.

How to Use a Digital Microscope to Streamline Inspection Processes

Watch this webinar for inspiration and expert advice on how to make quality control simpler, quicker, and easier. Learn how to perform comprehensive visual inspection, including comparison,…

Is that Document Genuine or Fake? How do They Identify Fake Documents?

This article shows how forensic experts use microscopy for analysis to identify counterfeit, fake documents, such as ID cards, passports, visas, certificates, etc. Then they know if it is genuine or…

測定可能な顕微鏡

光学顕微鏡は、品質管理、故障解析、研究開発において、試料の形状寸法測定にも役立ちます。ライカの光学顕微鏡の詳細をご覧ください。

バッテリー製造

バッテリー製造には、検査に関するいくつかの主な課題があります。サンプル前処理と顕微鏡による外観検査および拡張分析用のソリューションが必要です。

デジタル顕微鏡

デジタル顕微鏡は、接眼レンズのない顕微鏡です。 デジタルカメラが内蔵されています。 ライブ像がモニター画面に表示され、複数人で共有、画像保存、レポート出力に適しています。

応用分野

外観検査用顕微鏡

ライカマイクロシステムズは、工業用途向けのさまざまな検査用の光学顕微鏡を提供しています。 ライカから最適なソリューションをご提案いたします。

インダストリー用途別

光学顕微鏡は、部品やコンポーネントの検査、リワークや組み立て、品質保証/品質管理、故障解析、研究開発などの産業用途に使用することができます。具体的な用途としては、清浄度検査、鋼材の品質評価、金属組織学(鉄鋼/鋳物製品)などがあります。 これらのアプリケーションは、自動車や運輸、機械製造、電子機器や半導体、金属合金、医療機器など、多くの産業分野で一般的に必要とされています

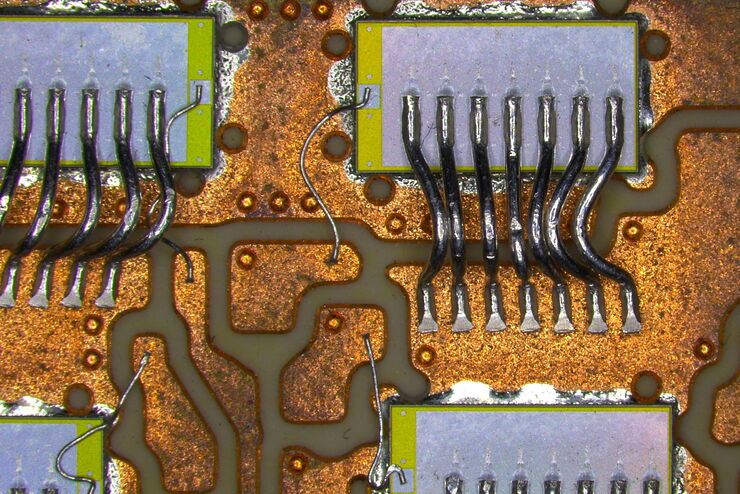

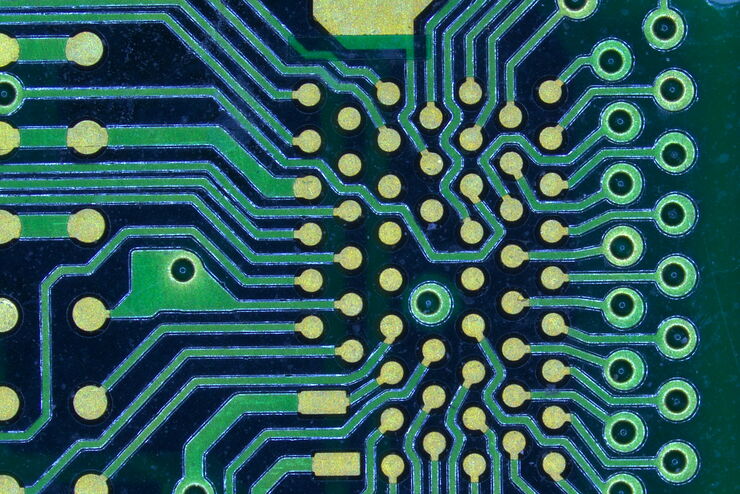

PCB検査

電子機器メーカーやサプライヤーは、迅速で信頼性の高いPCB検査のために、効率的な品質管理、断面解析、研究開発を可能にするソリューションを必要としています。

鉄鋼・金属

ライカの金属組織観察・分析ソリューションは、正確さと手軽さ、そしてスピード向上に寄与します

バッテリー製造

バッテリー製造には、検査に関するいくつかの主な課題があります。サンプル前処理と顕微鏡による外観検査および拡張分析用のソリューションが必要です。

測定可能な顕微鏡

光学顕微鏡は、品質管理、故障解析、研究開発において、試料の形状寸法測定にも役立ちます。ライカの光学顕微鏡の詳細をご覧ください。