EM TIC 3X Ion Beam Milling System

加工効率と柔軟性

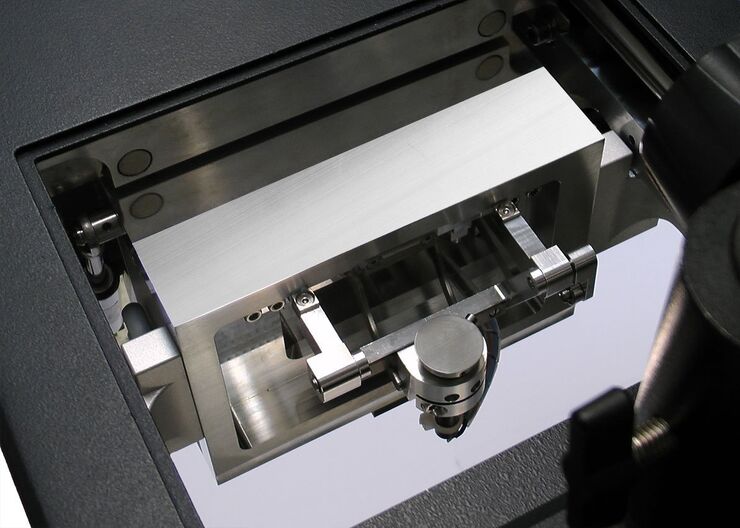

Rotary Stage

Rotary stage (retrofittable) has specially been designed for large area milling (flat milling). The ion beam prepared area is exceeding Ø 25 mm.

Download Brochure Rotary Stage

Standard Stage

Standard stage for routine applications and contrast enhancement of the prepared surface.

Multiple Sample Stage

Multiple sample stage is used if high throughput is desired. Three samples can be loaded and automatically processed in the Leica EM TIC 3X in one session (e.g. overnight) without any user interaction.

Cooling Stage

Cooling stage provides very low temperature processing. With temperatures of the sample holder and mask down to -160°C, extremely heat sensitive samples such as rubber, water soluble polymer fibers or even marshmallows (if desired) can be processed to a high quality.

Download Brochure Cooling Stage

Vacuum transfer docking station

Perfect for surfacing environmentally sensitive samples which can be subsequently transferred to coating and/or SEM systems under inert gas/vacuum conditions

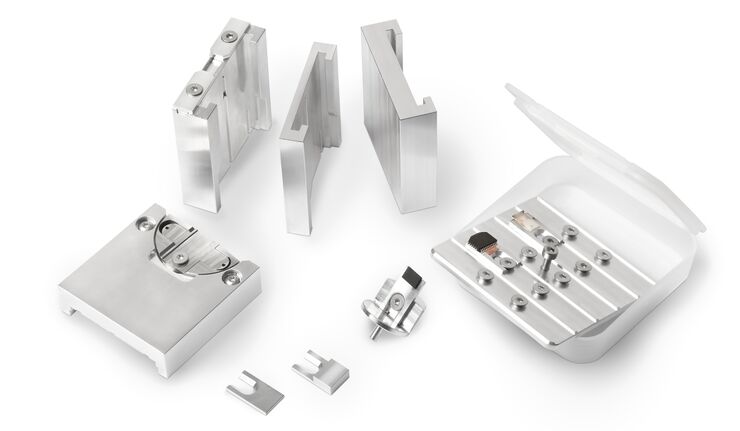

Various sample holders

Various sample holders for almost every sample size and a wide range of use are available e.g. one sample holder for the complete process from mechanical pre-preparation (Leica EM TXP) to ion beam slope cutting (Leica EM TIC 3X) to SEM investigation to the point of storage.

Sample holders for rotary stage

Sample holders for samples up to 12 mm height as well as adaptors for commercial available SEM stubs

Sample holders for high pressure frozen samples

Several holders are available for high pressure frozen samples.

Image left side - Cryo sample holder

Image right side - Cryo sample holder for samples up to 10 x 7 x 4 mm

Leica EM TIC 3X

Triple Ion-Beam Cutter

Rotary stage for Leica EM TIC 3X

Processing of a 25 mm Ø oil shale sample