LAS X Cleanliness Expert

製品紹介

Home

Leica Microsystems

LAS X Cleanliness Expert

汚染・コンタミネーション(コンタミ)を検査

最新の記事を読む

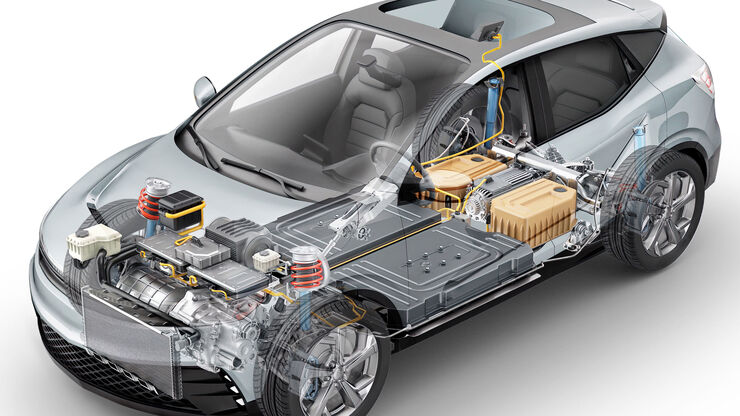

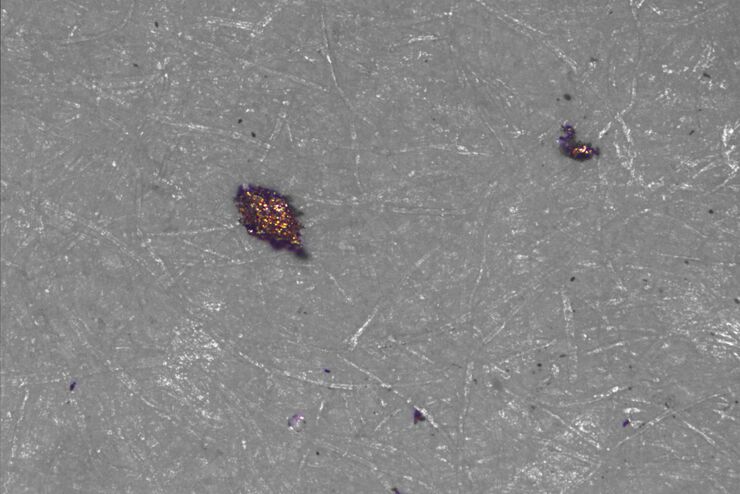

Battery Particle Detection During the Production Process

How battery particle detection and analysis is enhanced with optical microscopy and laser spectroscopy for rapid, reliable, and cost-effective QC during battery production is explained in this…

Key Factors for Efficient Cleanliness Analysis

An overview of the key factors necessary for technical cleanliness and efficient cleanliness analysis concerning automotive and electronics manufacturing and production is provided in this article.

Technical Cleanliness in the Automotive Industry for Electromobility

This free on-demand webinar covers the increasing focus on technical cleanliness in the automotive industry for electromobility and the VDA 19.1 revision.

3 Factors Determine the Damage Potential of Particles

This article discusses the 3 factors for determining the potential of a particle to cause damage to parts and components in the automotive and electronic industry. These factors include the…

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

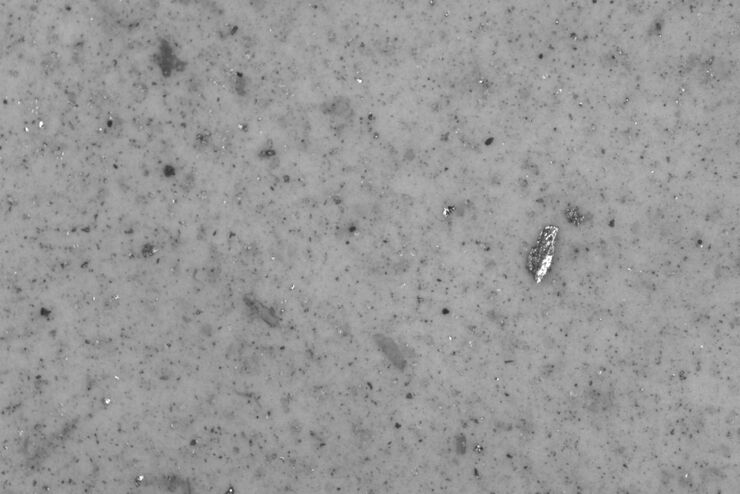

Cleanliness Analysis for Particulate Contamination

Devices, products, and their components fabricated in many industries can be quite sensitive to contamination and, as a result, have stringent requirements for technical cleanliness. Measurement…

Efficient Particle Counting and Analysis

This report discusses particle counting and analysis using optical microscopy for cleanliness of parts and components. Particle counting and analysis is a critical part of quality assurance in the…

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Cleanliness of Automotive Components and Parts

This article discusses the ISO 16232 standard and VDA 19 guidelines and briefly summarizes the particle analysis methods. They give important criteria for the cleanliness of automotive parts and…

応用分野

自動車&輸送機器業界

ライカのインテリジェントなイメージングソリューションは、現在および将来のニーズに対応し、お客様は技術革新に集中することができます。

清浄度評価

製品の機能と耐用期間は、粒子のコンタミネーションと関係し、粒子のコンタミネーションを定量的に検出することは、製造工程の改善につながります。

工業用光学顕微鏡

材料解析には、金属合金、半導体、ガラス、セラミック、プラスチック、ポリマーなど、さまざまな材料の画像処理、測定、分析のための顕微鏡ソリューションが必要です。

インダストリーマーケット別

稼働時間を最大化し、生産性向上により、お客様の収益に貢献します。ライカの顕微鏡(マイクロスコープ)ソリューションは、微細な異物や残渣なども見逃しなく、迅速かつ信頼性の高い分析、文書化、結果報告を実現します。ライカマイクロシステムズは、幅広いソリューションとエキスパートによるサポートを提供し、さまざまなアプリケーションのニーズにお応えします。