Filter articles

标签

Story Type

Products

Loading...

Workflow Solutions for Sample Preparation Methods for Material Science

This brochure presents and explains appropriate workflow solutions for the most frequently required sample preparation methods for material science samples.

Loading...

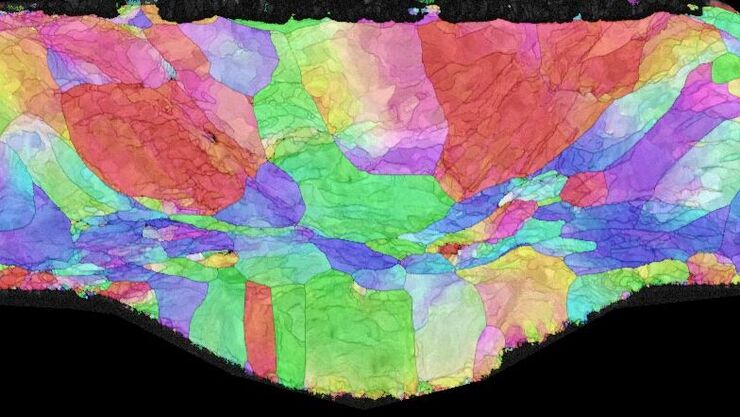

High-Quality EBSD Sample Preparation

This article describes a method for EBSD sample preparation of challenging materials. The high-quality samples required for electron backscatter diffraction are prepared with broad ion-beam milling.