Filter articles

标签

Products

Loading...

Automotive Part Verification and Development according to Specifications

Automotive part verification during the development and production of parts and components by suppliers or manufacturers is important for ensuring that specifications are met. Specifications are…

Loading...

Visualizing Photoresist Residue and Organic Contamination on Wafers

As the scale of integrated circuits (ICs) on semiconductors passes below 10 nm, efficient detection of organic contamination, like photoresist residue, and defects during wafer inspection is becoming…

Loading...

Burr Detection During Battery Manufacturing

See how optical microscopy can be used for burr detection on battery electrodes and determination of damage potential to achieve rapid and reliable quality control during battery manufacturing.

Loading...

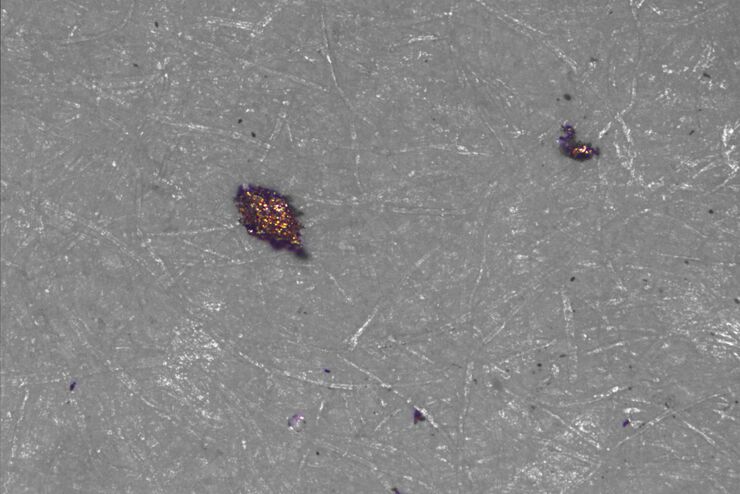

Battery Particle Detection During the Production Process

How battery particle detection and analysis is enhanced with optical microscopy and laser spectroscopy for rapid, reliable, and cost-effective QC during battery production is explained in this…

Loading...

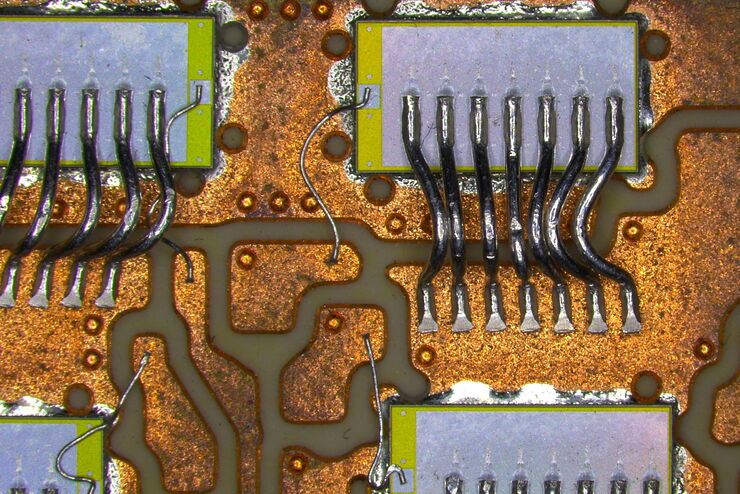

Structural and Chemical Analysis of IC-Chip Cross Sections

This article shows how electronic IC-chip cross sections can be efficiently and reliably prepared and then analyzed, both visually and chemically at the microscale, with the EM TXP and DM6 M LIBS…

Loading...

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

Loading...

Top Challenges for Visual Inspection

This article discusses the challenges encountered when performing visual inspection and rework using a microscope. Using the right type of microscope and optical setup is paramount in order to…

Loading...

Why is Manual Visual Inspection of Medical Devices so Challenging?

This article discusses how manual visual inspection, which is prevalent in the medical device industry, can lead to inconsistent results. It also addresses the challenges quality managers and…

Loading...

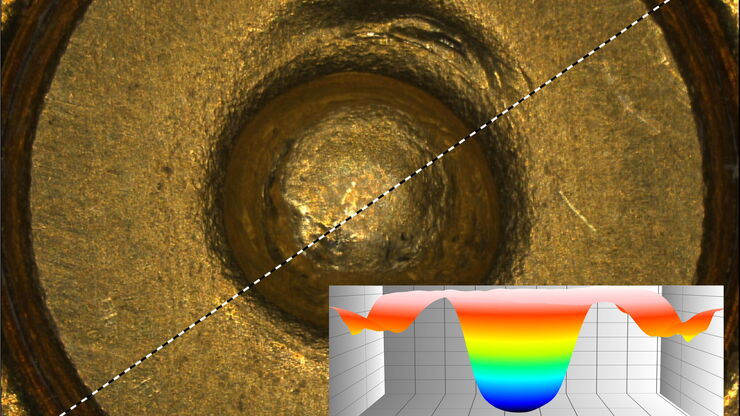

Topographic Analysis of Firing Pin Impressions on Cartridge Cases

The analysis of fired cartridges for primer cup morphology and flattening and firing pin impression (crater) depth using topographic data is discussed in this article. Topographical analysis of the…