DM6 M LIBS

Microscópios verticais

Microscópios óticos

Produtos

Página inicial

Leica Microsystems

DM6 M LIBS Solução de análise de composição de microestrutura

Economia de tempo de 90%: inspeção visual e química de materiais 2 em 1

Leia os nossos artigos mais recentes

Battery Particle Detection During the Production Process

How battery particle detection and analysis is enhanced with optical microscopy and laser spectroscopy for rapid, reliable, and cost-effective QC during battery production is explained in this…

Cross-section Analysis for Electronics Manufacturing

This article describes cross-section analysis for electronics concerning quality control and failure analysis of printed circuit boards (PCBs) and assemblies (PCBAs), integrated circuits (ICs), etc.

Structural and Chemical Analysis of IC-Chip Cross Sections

This article shows how electronic IC-chip cross sections can be efficiently and reliably prepared and then analyzed, both visually and chemically at the microscale, with the EM TXP and DM6 M LIBS…

Factors to Consider for a Cleanliness Analysis Solution

Choosing the right cleanliness analysis solution is important for optimal quality control. This article discusses the important factors that should be taken into account to find the solution that best…

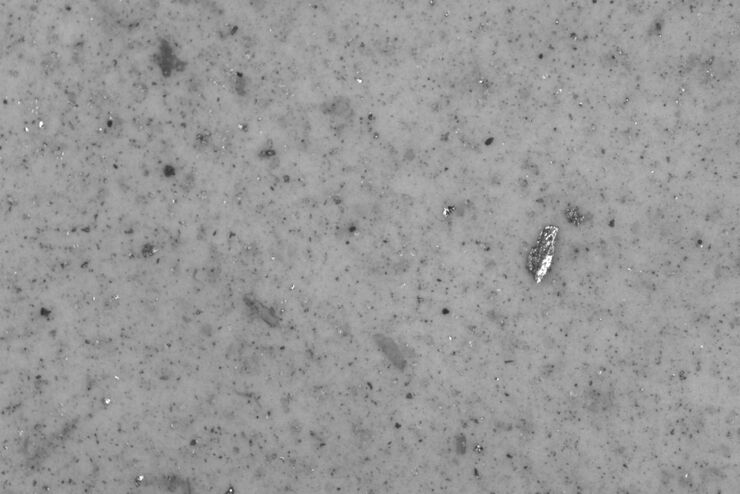

Efficient Particle Counting and Analysis

This report discusses particle counting and analysis using optical microscopy for cleanliness of parts and components. Particle counting and analysis is a critical part of quality assurance in the…

Quality Control Under the Microscope

Fast-rising demand for electric vehicles is one of the market’s main drivers, but there are other hotspots of growth, including the rise in renewable energy installations, such as photovoltaic panels,…

Cleanliness of Automotive Components and Parts

This article discusses the ISO 16232 standard and VDA 19 guidelines and briefly summarizes the particle analysis methods. They give important criteria for the cleanliness of automotive parts and…

Keeping Particulate Contamination Under Control in Pharmaceutical Products

This article describes how a 2-methods-in-1 solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) can be utilized for identification of particulate contaminants in the…

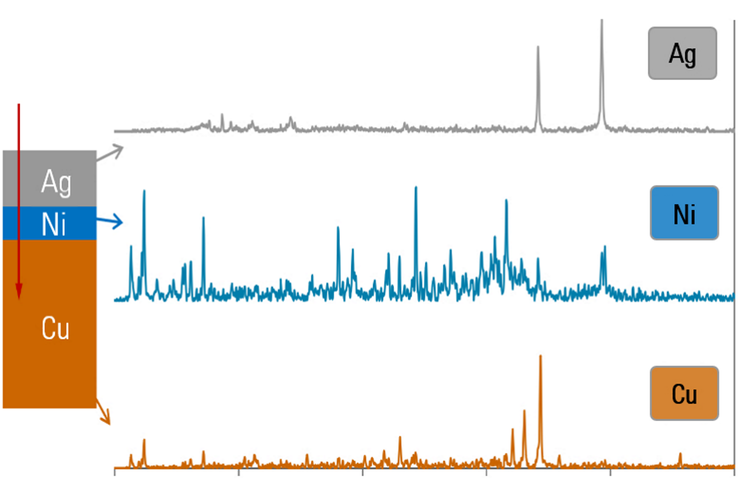

Depth Profiling and Layer Analysis for Inspection of Materials with a 2-In-1 Solution Combining Optical Microscopy and Laser Spectroscopy

In addition to simultaneous visual and chemical inspection, a 2-methods-in-1 materials analysis solution, which combines optical microscopy and laser induced breakdown spectroscopy (LIBS), can also be…

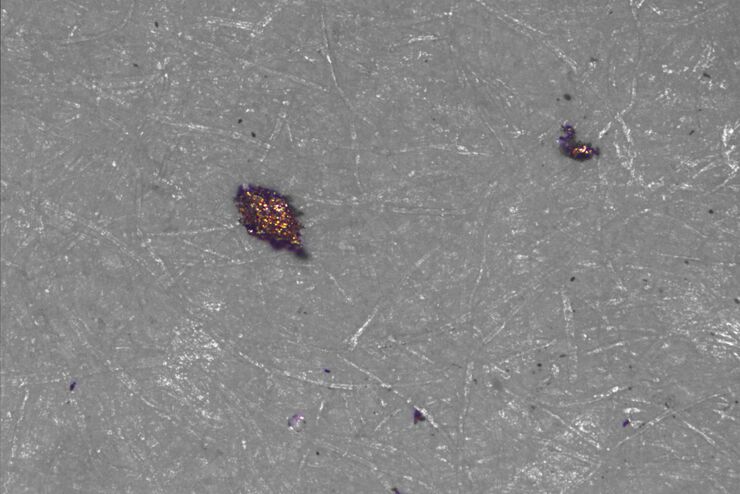

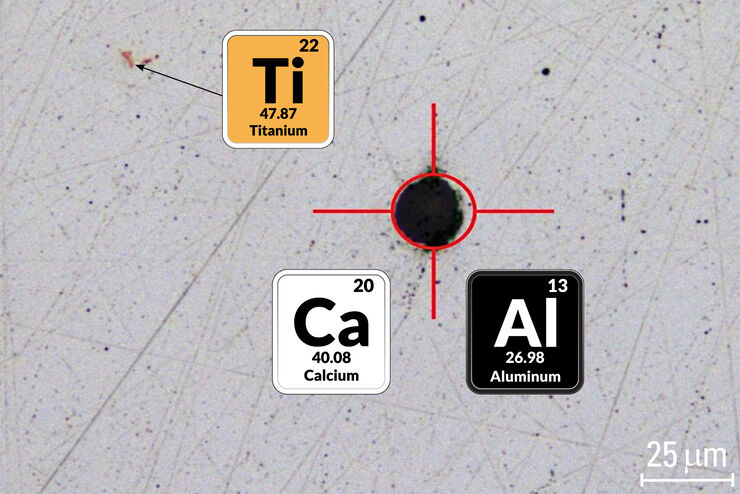

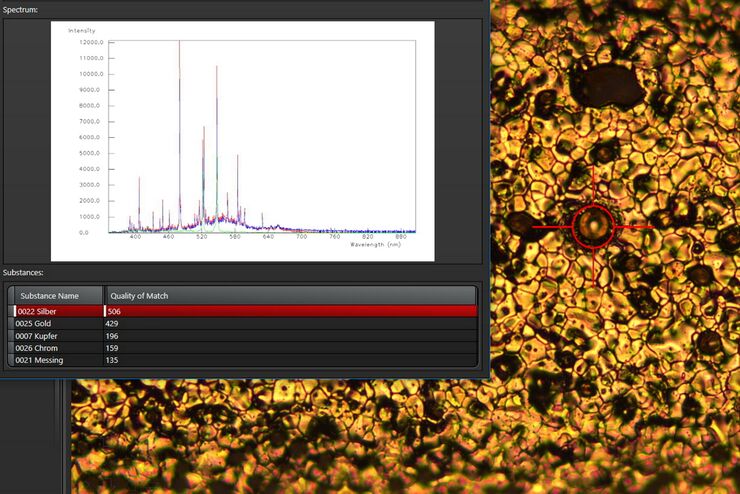

Visual and Chemical Analysis of Steel Microstructure: Faster Rating of Steel Quality

Simultaneous visual and chemical analysis of steel non-metallic inclusions with a 2-methods-in-1 solution, using optical microscopy and laser induced breakdown spectroscopy (LIBS), is described in…

See the Structure with Microscopy - Know the Composition with Laser Spectroscopy

The advantages of a 2-in-1 materials analysis solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) for simultaneous visual and chemical inspection are described in…

Fabricação de baterias

A fabricação de baterias tem vários desafios importantes relacionados à inspeção. São necessárias soluções para a preparação de amostras e para a análise microscópica visual e química.

Campos de aplicação

Metalografia

Os microscópios metalográficos da Leica são otimizados para a análise microestrutural de metais, ligas e outros materiais.

Automotivo e transporte microscópios

Nós, aqui na Leica, desejamos ser seu colaborador com o qual pode confiar, a fim de orientá-lo quanto às soluções ideais em captura e processamento de imagens, para que você possa estar à frente da…

Materiais & Ciências da Terra

Você precisa das ferramentas certas para imagens e análises confiáveis de alta qualidade. A Leica Microsystems é a fonte única para todas as suas necessidades de pesquisa. Juntamente com um suporte…

Limpeza técnica

Para fabricantes de produtos eletrônicos e industriais, bem como aplicações farmacêuticas não regulamentadas, as soluções para uma limpeza técnica eficiente oferecem vantagens significativas.

Microscópios de análise de materiais

A análise de materiais requer soluções de microscopia para a aquisição de imagens, medição e análise de recursos em diversos materiais, como ligas metálicas, semicondutores, vidro e cerâmica, bem como…

Mercados de microscopia industrial

Maximizar o tempo de atividade e atingir as metas de forma eficiente ajuda seu resultado final. As soluções de microscópio Leica podem fornecer uma visão dos menores detalhes da amostra, bem como…

Indústria metalúrgica

As soluções de microscopia da Leica para a indústria metalúrgica são úteis para avaliar a qualidade dos materiais e assegurar a conformidade com as normas aplicáveis.

Análise de cortes transversais para componentes eletrônicos

A análise de cortes transversais para componentes eletrônicos permite uma análise detalhada dos mecanismos de falha de componentes, como placas de circuito impresso (PCBs), conjuntos (PCBAs) e…

Indústria de eletrônicos e semicondutores

Para eletrônicos e semicondutores, soluções que permitem a inspeção eficiente, análise de seção transversal e limpeza, além da P&D de PCBs, wafers, chips IC e baterias são cruciais.

Fabricação de baterias

A fabricação de baterias tem vários desafios importantes relacionados à inspeção. São necessárias soluções para a preparação de amostras e para a análise microscópica visual e química.

Microscópios de medição

Os microscópios de medição são úteis para determinar as dimensões de detalhes das amostras durante o controle de qualidade, análise de falhas e P&D. Saiba mais sobre os microscópios de medição da…